Laser diode chips, bars stacks are the key components in laser pumping, industrial laser processing and advanced machining. We can provide various chips, bars and stacks in the wavelengths 0.75-1.06um, single emitters and chips at single mode and mult

Laser diode chips, bars & stacks are the key components in laser pumping, industrial laser processing and advanced machining. We can provide various chips, bars and stacks in the wavelengths 0.75-1.06um, single emitters and chips at single mode and multi-mode, a few hundred watts, COS/COC/MCC packages. Customized products are available upon request. These products are widely used in laser industrial material processing, medical application, communications, safety protection, intelligent sensing, and scientific research.

(1) High-power Single Emitter Laser Chips – BC Series

| Optical | |||||

| Center Wavelength | nm | 915 | 915 | 976 | 976 |

| Wavelength Tolerance | nm | ±10 | ±10 | ±3 | ±3 |

| Output Power | W | 25 | 30 | 25 | 30 |

| Operating Mode | # | CW | CW | CW | CW |

| Fast-axis Divergence | Deg | 55 | 55 | 55 | 55 |

| Slow-axis Divergence | Deg | 9.5 | 9.5 | 9.5 | 9.5 |

| Spectral Width (FWHM) | nm | 4 | 4 | 4 | 4 |

| Wavelength Temp Coefficient | nm/℃ | 0.3 | 0.3 | 0.33 | 0.33 |

| TE Polarization | % | 97 | 97 | 97 | 97 |

| Electrical | |||||

| Emitter Width | μm | 195 | 230 | 195 | 230 |

| Cavity Length | mm | 4.5 | 4.5 | 4.5 | 4.5 |

| Width | μm | 400 | 400 | 400 | 400 |

| Thickness | μm | 145 | 145 | 145 | 145 |

| Geometric | |||||

| Electro-optic Conversion Eff. | % | 62 | 62 | 63 | 63 |

| Slope Efficiency | W/A | 1.15 | 1.15 | 1.1 | 1.1 |

| Thershold Current | A | 1.5 | 1.8 | 1.1 | 1.5 |

| Operating Current | A | 25 | 30 | 25 | 30 |

| Operating Voltage | V | 1.65 | 1.65 | 1.55 | 1.55 |

(2) High-power Diode Bar – BB Series

| Optical | |||||||

| Center Wavelength | nm | 808 | 808 | 808 | 808 | 940 | 940 |

| Wavelength Tolerance | nm | ±10 | ±10 | ±10 | ±3 | ±3 | ±3 |

| Output Power | W | 50 | 60 | 100 | ≥500 | 200 | ≥700 |

| Fast-axis Divergence | Deg | ≤65 | ≤65 | ≤65 | ≤65 | ≤55 | ≤55 |

| Slow-axis Divergence | Deg | ≤8.5 | ≤8.5 | ≤8.5 | ≤8.5 | ≤8.5 | ≤8.5 |

| Spectral Width (FWHM) | nm | ≤2.5 | ≤2.5 | ≤3 | ≤3.5 | ≤3 | 5 |

| TE Polarization | TM/TE | TE | TE | TE | TE | TE | TE |

| Wavelength Temp Coefficient | nm/℃ | 0.28 | 0.28 | 0.28 | 0.28 | 0.3 | 0.3 |

| Electrical | |||||||

| Electro-optic Conversion Eff | % | ≥55 | ≥55 | ≥55 | ≥58 | ≥63 | ≥63 |

| Slope Efficiency | W/A | 1.25 | 1.25 | 1.25 | 1.25 | 1 | 1.15 |

| Threshold Current | A | 8 | 12 | 15 | 25 | 25 | 25 |

| Operating Current | A | 50 | 60 | 105 | ≤430 | 220 | 650 |

| Operating Voltage | V | 1.8 | 1.8 | 1.8 | 2.0 | 1.55 | 1.7 |

| Pulse Width | us | - | - | - | 200 | - | 500 |

| Pulse frequency | Hz | - | - | - | 400 | - | 160 |

| Pulse duty cycle | % | - | - | - | 8 | - | 8 |

| Geometric | |||||||

| Number of Emitters | # | 19 | 49 | 49 | 34 | 24 | 34 |

| Emitter Width | μm | 150 | 100 | 100 | 232 | 200 | 232 |

| Emitter Pitch | μm | 500 | 200 | 200 | 290 | 400 | 290 |

| Fill Factor | % | 30 | 50 | 50 | 80 | 50 | 80 |

| Cavity Length | mm | 1.0 | 1.0 | 1.5 | 1.5 | 3 | 2 |

| Bar Thickness | μm | 145 | 145 | 145 | 115 | 115 | 115 |

| Bar Length | mm | 10 | 10 | 10 | 10.25 | 10.25 | 10.25 |

| Thermal | |||||||

| Operating Temperature | ℃ | 25 | 25 | 25 | 25 | 20 | 25 |

| Storage Temperature | ℃ | 40~80 | -40~80 | 40~80 | 40~80 | -40~80 | 40~80 |

| Flow Velocity | L/min | / | 0.25 | 0.25 | 0.20 | 0.25 | 0.25 |

(3) High-power Diode VCSEL Chips – TOF series

| Optical | |||||

| Center Wavelength@Iop | nm | 808 | 850 | 940 | 940 |

| Spectral width (half width) | nm | 2 | 2 | 2 | 2 |

| Wavelength shift / temperature | nm/℃ | 0.07 | 0.07 | 0.07 | 0.07 |

| Emitter aperture | μm | 10 | 10 | 10 | 10 |

| Emitter minimum pitch | μm | 44 | 47 | 33 | 40 |

| Emitter number | / | 621 | 1216 | 305 | 364 |

| Output Power | W | 3.1 | 4 | 2.1 | 3.1 |

| Operating current | A | 3.5 | 5 | 2.8 | 3.5 |

| Power consumption | W | 7 | 10 | 5.6 | 7 |

| Operating Voltage | V | 2 | 2 | 2 | 2 |

| Operating efficiency | % | 35 | 40 | 40 | 40 |

| Threshold current | A | 0.7 | 1.2 | 0.38 | 0.47 |

| Divergence angle | ° | 22 | 22 | 20 | 20 |

| Geometric | |||||

| Emitter length | μm | 916 | 1535 | 525 | 916 |

| Emitter width | μm | 901 | 1560 | 615 | 610 |

| Chip length | μm | 1206 | 1845 | 695 | 996 |

| Chip width | μm | 1006 | 1670 | 795 | 890 |

| Chip thickness | μm | 100 | 100 | 100 | 100 |

(4) High-power Diode VCSEL Chips – SL Series

| Optical | ||||

| Center Wavelength@Iop | nm | 934 | 940 | 946 |

| Spectral width (half width) | nm | 2 | ||

| Wavelength shift / temperature | nm/℃ | 0.07 | ||

| Emitter aperture | μm | 8 | ||

| Emitter minimum pitch | μm | 21 | ||

| Emitter number(Area A) | - | 377 | ||

| Emitter number(Area B) | - | 6 | ||

| Output Power(Area A) | W | 1.3 | 1.5 | 1.7 |

| Output Power(Area B) | W | 0.024 | ||

| Single point power | W | 0.004 | ||

| Operating current(Area A) | A | 3.6 | ||

| Operating current(Area B) | A | 0.06 | ||

| Power consumption(Area A) | W | 3.6 | ||

| Power consumption(Area B) | W | 0.06 | ||

| Operating Voltage | V | 2 | ||

| Operating efficiency | % | 40 | 45 | |

| Threshold current(Area A) | A | 0.38 | ||

| Threshold current(Area B) | A | 0.006 | ||

| Divergence angle | ° | 20 | ||

| Geometric | ||||

| Luminous zone length | μm | 523 | ||

| Light-emitting area width | μm | 548 | ||

| Chip length | μm | 758 | 778 | 798 |

| Chip width | μm | 701 | 721 | 741 |

| Chip thickness | μm | 90 | 100 | 110 |

(5) High-power Diode VCSEL Chips – LI Series

| Optical | |||

| Center Wavelength | nm | 905 | 940 |

| Spectral width (half width) | nm | 2 | 2 |

| Wavelength shift / temperature | nm/℃ | 0.07 | 0.07 |

| Emitter aperture | μm | 12 | 12 |

| Emitter minimum pitch | μm | 22 | 22 |

| Emitter number | / | 136 | 136 |

| Output Power | W | 60 | 60 |

| Operating current | A | 15 | 15 |

| Power consumption | W | 300 | 300 |

| Operating Voltage | V | 25 | 25 |

| Operating efficiency | % | 20 | 20 |

| Threshold current | A | 0.2 | 0.2 |

| Divergence angle | ° | 20 | 20 |

| Geometric | |||

| Emitter length | μm | 273 | 273 |

| Emitter width | μm | 288 | 288 |

| Chip length | μm | 520 | 520 |

| Chip width | μm | 401 | 401 |

| Chip thickness | μm | 100 | 100 |

(6) High-power Diode Laser Device – COS Series

| Optical | |||||

| Center Wavelength | nm | 915 | 915 | 976 | 976 |

| Wavelength Tolerance | nm | ±10 | ±10 | ±3 | ±3 |

| Output Power | W | 25 | 30 | 25 | 30 |

| Operating Mode | # | CW | CW | CW | CW |

| Fast-axis Divergence | Deg | 55 | 55 | 55 | 55 |

| Slow-axis Divergence | Deg | 9.5 | 9.5 | 9.5 | 9.5 |

| Spectral Width (FWHM) | nm | 4 | 4 | 4 | 4 |

| Wavelength Temperature Coefficient | nm/℃ | 0.3 | 0.3 | 0.33 | 0.33 |

| TE Polarization | % | 97 | 97 | 97 | 97 |

| Electrical | |||||

| Electrio-optic Conversion Eff | % | 62 | 62 | 63 | 63 |

| Slope Efficiency | W/A | 1.15 | 1.15 | 1.1 | 1.1 |

| Thershold Current | A | 1.5 | 1.8 | 1.1 | 1.5 |

| Operating Current | A | 25 | 30 | 25 | 30 |

| Operating Voltage | V | 1.65 | 1.65 | 1.55 | 1.55 |

| Geometric | |||||

| Emitter Width | μm | 195 | 230 | 195 | 230 |

| Cavity Length | mm | 4.5 | 4.5 | 4.5 | 4.5 |

| Width | μm | 400 | 400 | 400 | 400 |

| Thickness | μm | 145 | 145 | 145 | 145 |

(7) High-power Diode Laser Devices – MCC Series

| Optical | |||||||

| Center Wavelength | nm | 808 | 808 | 808 | 808 | 940 | 940 |

| Wavelength Tolerance | nm | ±10 | ±10 | ±10 | ±10 | ±3 | ±3 |

| Output Power | W | 50 | 60 | 100 | ≥500 | 200 | 200 |

| Fast-axis Divergence | Deg | ≤65 | ≤65 | ≤65 | ≤65 | ≤55 | ≤55 |

| Slow-axis Divergence | Deg | ≤8.5 | ≤8.5 | ≤8.5 | ≤8.5 | ≤8.5 | ≤8.5 |

| Spectral Width (FWHM) | nm | ≤2.5 | ≤2.5 | ≤3 | ≤3.5 | ≤3 | ≤3 |

| Polarization Mode | TM/TE | TE | TE | ||||

| Wavelength Temperature Coefficient | nm/℃ | 0.28 | 0.28 | 0.28 | 0.28 | 0.3 | 0.3 |

| Electrical | |||||||

| Electrio-optic Conversion Eff | % | ≥55 | ≥55 | ≥55 | ≥58 | ≥63 | ≥63 |

| Slope Efficiency | W/A | 1.25 | 1.25 | 1.25 | 1.25 | 1 | 1.15 |

| Thershold Current | A | 8 | 12 | 15 | 25 | 25 | 25 |

| Operating Current | A | 50 | 60 | 105 | ≤430 | 220 | 650 |

| Operating Voltage | V | 1.8 | 1.8 | 1.8 | 2.0 | 1.55 | 1.7 |

| Pulse Width | us | - | - | - | 200 | - | 500 |

| Pulse frequency | Hz | - | - | - | 400 | - | 160 |

| Pulse Duty Cycle | % | - | - | - | 8 | - | 8 |

| Geometric | |||||||

| Number of Emitters | # | 19 | 49 | 49 | 34 | 24 | 34 |

| Emitter Width | μm | 150 | 100 | 100 | 232 | 200 | 232 |

| Emitter Pitch | μm | 500 | 200 | 200 | 290 | 400 | 290 |

| Fill Factor | % | 30 | 50 | 50 | 80 | 50 | 80 |

| Cavity Length | mm | 1.0 | 1.0 | 1.5 | 1.5 | 3 | 2 |

| Bar Thickness | μm | 145 | 145 | 145 | 115 | 115 | 115 |

| Bar Length | mm | 10 | 10 | 10 | 10.25 | 10.25 | 10.25 |

| Thermal | |||||||

| Operating Temp. | ℃ | 25 | 25 | 25 | 25 | 20 | 25 |

| Storage temp. | ℃ | -40~80 | -40~80 | -40~80 | -40~80 | -40~80 | -40~80 |

| Water Flow Rate | L/min | / | 0.25 | 0.25 | 0.20 | 0.25 | 0.25 |

(8) High-power Diode Laser Stacks – MCP Series

| Optical | ||||

| Center Wavelength | nm | 808 | 808 | 808 |

| Wavelength Tolerance | nm | ±10 | ±10 | ±3 |

| Output Power | W | 60 | 100 | 300 |

| Number of Bars | # | 2 ~ 60 | 2 ~ 60 | 2 ~ 60 |

| Spectral Width (FWHM) | nm | ≤8 | ≤8 | 4 |

| Operating Mode | # | CW | CW | QCW |

| Fast-axis Divergence | Deg | ≤42 | ≤42 | 40 |

| Slow-axis Divergence | Deg | ≤10 | ≤10 | 10 |

| Wavelength Temp Coefficient | nm/℃ | 0.28 | 0.28 | 0.28 |

| Electrical | ||||

| Power Conversion Efficiency | % | 50 | 50 | 50 |

| Slope Efficiency/Bar | W/A | ≥1.1 | ≥1.1 | 1.1 |

| Threshold Current | A | 4.5 | 4.5 | 4.5 |

| Operating Current | A | 0.16 | 0.16 | 290 |

| Operating Voltage/Bar | V | ≤2 | ≤2 | 1.8 |

| Thermal | ||||

| Operating Temperature | ℃ | 15 ~ 35 | 15 ~ 35 | 25 |

| Storage Temperature | ℃ | 0~55 | 0~55 | 0~55 |

| Bar/Water Velocity/Bar | l/m | 0.3~0.5 | 0.3~0.5 | 0.3 |

| Entrace Maximum Pressure | psi | 55 | 55 | 55 |

| Water Type | - | DI Water | DI Water | DI Water |

| Deionized Water Resistivity(DI) | kΩ·cm | 200~500 | 200~500 | 200~500 |

| Pure Water Filter Particles | μm | <20 | <20 | <20 |

(9) High-power Diode Laser Stacks – QCP Series

| Optical | |||

| Center Wavelength | nm | 808 | 808 |

| Wavelength Tolerance | W | ±3 | ±10 |

| Bar Output Power/Bar | % | 300 | 40 |

| Number of Bars | % | 2 ~ 24 | 60 |

| Total Output Power | μm | - | 2400 |

| Bar-to-Bar Spacing | - | 0.4 ~ 1.8 | 0.9 |

| Spectral Width (FWHM) | - | 4 | 8 |

| Pulse Width | m | 50-500 | 10-100 |

| Repetition Rate | 1-200 | 1-10 | |

| Fast-axis Divergence(FWHM) | nm | 40 | 40 |

| Slow-axis Divergence(FWHM) | mW | 10 | 10 |

| Wavelength Temp Coefficient | 0.28 | 0.28 | |

| Electrical | |||

| Electro-optic Conversion Eff | % | 50 | 50 |

| Slope Efficiency/Bar | W/A | 1.1 | 1.1 |

| Threshold Current | A | 20 | 10 |

| Operating Current | A | 300 | 50 |

| Operating Voltage/Bar | V | 2 | 1.8 |

| Thermal | |||

| Water Type | - | Pure Water | Pure Water |

| Operating Temperature | ℃ | 25 | 25 |

| Storage Temperature | ℃ | -40-85 | -40-85 |

(10) High-power Diode Laser Devices – TO Series

| Optical | ||||

| Min | Typical | Max | ||

| Center Wavelength | nm | 820 | 830 | 840 |

| Wavelength Tolerance | nm | ±10 | ||

| Output Power | W | 1.0 | ||

| Spectral Width(FWHM) | nm | 3.0 | 4.0 | |

| Wavelength Temp Coefficient | nm/℃ | 0.3 | ||

| Electrical | ||||

| Electro-optic Conversion Eff | % | 36 | 42 | |

| Slope Efficiency | W/A | 1.05 | 1.1 | |

| Threshold Current | A | 0.38 | 0.45 | |

| Operating Current | A | 1.28 | 1.40 | |

| Operating Voltage | V | 1.8 | 2.2 | |

| Thermal | ||||

| Operating Temperature | ℃ | 0 | 25 | 40 |

| Storage Temperature | ℃ | -20~70 |

We, a diode laser company, manufacture high-power diode lasers and systems in a wide range of output powers and wavelengths Including wafer growth and slicing, fiber coupling and bar stacking laser. More than 1000 models are for your choice. Established in 2011, over 60 technicians and 2 scientists, 20 of them are PHD degree. Production site is 1000Class Lab Clean Room with 5000sqm. Our current turnover per year is about 20million US Dollars with 30% growth year on year. Our strengths are in talent employees, quality engineering, process control, product development and volume manufacturing.

Optical

| Central Wavelength | 755nm,808nm,830nm,905nm,940nm,976nm,1550nm |

| Wavelength Tolerance | ±10nm, ±5nm, ±3nm |

| Output Power | 2W,10W,20W,50W,100W,150W,200W,300W,500W,1000W |

| Working Mode | CW/QCW/Single Mode |

| Number of Emitter | 1~60 |

| Filling Factor | 30%~75% |

| Cavity Length | 1000um/1500um/2000um/3000um/4000um |

Electrical

| Working Current | 1~300A |

| Threshold Current | 0.5~50A |

| Working Voltage | 1.8~2.1V |

| Power Conversion Eff | 30%~60% |

Thermal

| Working Temp | 25℃ |

| Storage Temp | -30-80℃ |

| Wavelength Temp Coefficient | ~0.3nm/℃ |

Optical

| Central Wavelength | 755nmm, 808nm, 915nm, 940nm, 976nm, 1064nm |

| Wavelength Tolerance | ±10nm, ±5nm, ±3nm |

| Output Power Per Bar | 20W/40W/80W/100W/200W/300W~30000W |

| Number of Bars | 1~60pcs |

| Working Mode | CW/QCW |

Electrical

| Working Current | 1~300A |

| Threshold Current | 0.5~50A |

| Working Voltage | 1~40V |

| Power Conversion Eff | 30%~60% |

Optional functions: FAC lens, SAC lens.

Thermal

| Working Temp | -20~70℃ |

| Storage Temp | -30-80℃ |

| Wavelength Temp Coefficient | ~0.3nm/℃ |

| Cooling Way | Water Cooled/TEC/Conduction Cooled/Air Cooled |

Semiconductor lasers are one of most of today’s industrial lasers. Whether direct material processing or optical pumping of solid-state lasers, fiber lasers or disc lasers, the unmounted single emitters and bars are the key component for the initial conversion of electrical energy into light.

Semiconductor lasers are one of most of today’s industrial lasers. Whether direct material processing or optical pumping of solid-state lasers, fiber lasers or disc lasers, the unmounted single emitters and bars are the key component for the initial conversion of electrical energy into light.

We have been focusing on the semiconductor wafer technology from 1998, delivers the multimode high power at wavelengths between 808 and 1064nm.

High Power multimode unmounted bars up to 40W CW and 200W QCW output

Unmounted single emitters up to 2W CW Power

Available wavelengths include 808nm and 980nm

| Part No. | Wavelength | Output Power | Emitter Width | Cavity Length | Width |

| STHT-CLDM-0808-0500-02 | 808±5nm | 500mW | 50µm | 600µm | 500µm |

| STHT-CLDM-0808-1000-02 | 808±5nm | 1W | 100µm | 900µm | 500µm |

| STHT-CLDM-0808-2000-02 | 808±5nm | 2W | 100/150µm | 1500/1000µm | 500µm |

| STHT-CLDM-0980-0500-02 | 980±10nm | 500mW | 50µm | 600µm | 500µm |

| STHT-CLDM-0980-1000-02 | 980±10nm | 1W | 100µm | 900µm | 500µm |

| STHT-CLDM-0980-2000-02 | 980±10nm | 2W | 150µm | 1000µm | 500µm |

| Unmounted Bars | Wavelength | Output Power | Operation Mode | Fill Factor | Number of single emitters |

| STHT-LDAC1-0808-0020 | 808±5nm | 20W | CW | 20% | 19 |

| STHT-LDAC1-0808-0040 | 808±5nm | 40W | CW | 30% | 19 |

| STHT-LDAQ1-0808-0100 | 808±5nm | 100W | QCW | 87% | 100 |

| STHT-LDAQ1-0808-0200 | 808±5nm | 200W | QCW | 71% | 58 |

LDM series packaged single emitters are Fabry-Perot cavity semiconductor lasers based on Quantum-well epitaxy and ridge waveguide structure design. Sintec packaged single emitters provide excellent reliability and performance.

LDM series packaged single emitters are Fabry-Perot cavity semiconductor lasers based on Quantum-well epitaxy and ridge waveguide structure design. Sintec packaged single emitters provide excellent reliability and performance.

Center wavelength includes 635nm, 650nm, 670nm, 785nm, 808nm, 830nm, 9xxnm and 1064 nm

Package designs include TO mounts, COS mounts, C-mounts and F-mounts

Provide beam shaping services like fast-axis compression according to customer demands

| Part No. | Wavelength nm | Output Power(20°C) | Operating Current | Operating Voltage | Package |

| STHT-LDM-0635-500m | 635 | 500mW | ≤1.35A | ≤2.3V | C-Mount / TO3 |

| STHT-LDM-0650-300m | 650 | 300mW | ≤1.0A | ≤2.3V | C-Mount / TO3 |

| STHT-LDM-0670-300m | 670 | 300mW | ≤1.0A | ≤2.3V | C-Mount / TO3 |

| STHT-LDM-0808-200m | 808 | 200mW | ≤220mA | ≤2.0V | TO56 |

| STHT-LDM-0808-300m | 808 | 300mW | ≤330mA | ≤2.0V | TO56 |

| STHT-LDM-0808-500m | 808 | 500mW | ≤560mA | ≤2.0V | TO9 |

| STHT-LDM-0808-001W | 808 | 1W | ≤1.24A | ≤2.0V | TO9 |

| STHT-LDM-0808-002W | 808 | 2W | ≤2.1A | ≤2.0V | CoS/ F-Mount /C-Mount |

| STHT-LDM-0808-003W | 808 | 3W | ≤3.3A | ≤2.0V | CoS/ F-Mount/ C-Mount |

| STHT-LDM-0808-005W | 808 | 5W | ≤5.5A | ≤2.0V | CoS/ F-Mount/ C-Mount |

| STHT-LDMP-0808-007W | 808 | 7W (ms pulse) | ≤7.8A | ≤3.0V | TO56 |

| STHT-LDM-0808-008W | 808 | 8W | ≤10A | ≤2.0V | CoS/ F-Mount/ C-Mount |

| STHT-LDM-0830-001W | 830 | 1W | ≤1.3A | ≤2.0V | CoS/ C-Mount |

| STHT-LDMP-0830-005W | 830 | 5W (ms pulse) | ≤5.30A | ≤3.0V | TO56 |

| STHT-LDM-0915-010W | 915 | 10W | ≤11A | ≤2.2V | CoS/ F-Mount |

| STHT-LDM-0940-003W | 940 | 3W | ≤3.2A | ≤2.0V | CoS/ F-Mount/ C-Mount |

| STHT-LDM-0980-500m | 980 | 500mW | ≤700mA | ≤2.0V | TO9 |

| STHT-LDM-0980-001W | 980 | 1W | ≤1.3A | ≤2.0V | TO9 |

| STHT-LDM-0980-002W | 980 | 2W | ≤2.3A | ≤2.0V | CoS/ C-Mount |

| STHT-LDM-0980-003W | 980 | 3W | ≤3.6A | ≤2.0V | CoS/ C-Mount |

| STHLDMP-980-005W | 980 | 5W (ms pulse) | ≤5.8A | ≤3.0V | TO56 |

LDA series high power packaged bars provide OEM customers with scalable power up to kilowatts for pumping, industrial, medical and applications. The packaged laser bars can be configured for enhanced brightness through stacking, scaled linearly or vertically for optimized light and material integration. LDA series offer:

LDA series high power packaged bars provide OEM customers with scalable power up to kilowatts for pumping, industrial, medical and applications. The packaged laser bars can be configured for enhanced brightness through stacking, scaled linearly or vertically for optimized light and material integration. LDA series offer:

Wavelengths at 808nm to 1100nm range

Modular and Compact design for ease of integration

Up to 100W CW and 300W QCW laser diode bars for high brightness

Packaged 10mm laser diode bar, various standard bar configurations (custom bar configurations available on request)

| Packaged Bars | Center Wavelength | Output Power | Operation Mode | Cooling |

| STHT-LDAC1-0808-020W | 808nm | 20W | CW | Conduction-cooled |

| STHT-LDAC1-0808-040W | 808nm | 40W | CW | Conduction-cooled |

| STHT-LDAC1-0808-060W | 808nm | 60W | CW | Conduction-cooled |

| STHT-LDAC1-09xx-060W | 9xxnm | 60W | CW | Conduction-cooled |

| STHT-LDAC1-1064-040W | 1064nm | 40W | CW | Conduction-cooled |

| STHT-LDAC1-0808-040W | 808nm | 40W | CW | Microchannel-cooled |

| STHT-LDAC1-0808-060W | 808nm | 60W | CW | Microchannel-cooled |

| STHT-LDAC1-0808-100W | 808nm | 100W | CW | Microchannel-cooled |

| STHT-LDAC1-09xx-060W | 9xxnm | 60W | CW | Microchannel-cooled |

| STHT-LDAC1-1064-040W | 1064nm | 40W | CW | Microchannel-cooled |

| STHT-LDAQ1-0808-100W | 808nm | 100W | QCW | Conduction-cooled |

| STHT-LDAQ1-0808-200W | 808nm | 200W | QCW | Conduction-cooled |

| STHT-LDAQ1-0808-300W | 808nm | 300W | QCW | Conduction-cooled |

| Vertical Arrays | Center Wavelength | Power per bar | Operation Mode | Cooling |

| STHT-LDAC2-0808-xxx | 808nm | 40-100W | CW | Microchannel-cooled |

| STHT-LDAC2-09xx-xxx | 9xxnm | 40-100W | CW | Microchannel-cooled |

| STHT-LDAC2-1064-040W | 1064nm | 40W | CW | Microchannel-cooled |

| STHT-LDAQ2-0808-xxx | 808nm | 100-300W | QCW | Conduction-cooled |

| STHT-LDAQ2-0940-xxx | 940nm | 100-200W | QCW | Conduction-cooled |

| Horizontal Arrays | Center Wavelength | Power per bar | Operation Mode | Cooling |

| STHT-LDAC3-0808-xxx | 808nm | 40-100W | CW | Microchannel-cooled |

| STHT-LDAC3-09xx-xxx | 9xxnm | 40-100W | CW | Microchannel-cooled |

| STHT-LDAC3-1064-040W | 1064nm | 40W | CW | Microchannel-cooled |

| STHT-LDAC3-0808-xxx | 808nm | 40-100W | CW | Macrochannel-cooled |

| STHT-LDAC3-09xx-xxx | 9xxnm | 40-100W | CW | Macrochannel-cooled |

| STHT-LDAC3-1064-040W | 1064nm | 40W | CW | Macrochannel-cooled |

| STHT-LDAQ3-0808-xxx | 808nm | 100-300W | QCW | Macrochannel-cooled |

| STHT-LDAQ3-0940-xxx | 940nm | 100-200W | QCW | Macrochannel-cooled |

9xxnm center wavelength includes 915nm/940nm/980nm.

Please contact us to discuss your specific requirements.

The vertical arrays specially designed for hair removal application, can stack up to 10 packaged laser bars to form a high power diode laser assembly. Each of these laser bars individually provides up to 100watts in CW mode. The small gaps between the laser bars make the module obtain maximum brilliance from the arrays, enabling the module to work with high efficiency

The vertical arrays specially designed for hair removal application, can stack up to 10 packaged laser bars to form a high power diode laser assembly. Each of these laser bars individually provides up to 100watts in CW mode. The small gaps between the laser bars make the module obtain maximum brilliance from the arrays, enabling the module to work with high efficiency

Power up to 1000W

Compact designs

Reliable package with hard solder

| Part No. | STHT-LDAQ2-0808-300 | STHT-LDAQ2-0808-500 | STHT-LDAQ2-0808-800 | STHT-LDAQ2-0808-1000 |

| Operation Mode | QCW | QCW | QCW | QCW |

| Center Wavelength nm | 808 ± 10 | 808 ± 10 | 808 ± 10 | 808 ± 10 |

| Output Power W | 300 | 500 | 800 | 1000 |

| Bar Numbers | 5/ 6 | 10 | 8 | 10 |

| Operating Current A | ≤50 | ≤50 | ≤100 | ≤100 |

| Operating Voltage V/bar | ≤2 | ≤2 | ≤2 | ≤2 |

| Pulse Width ms | ≤400 | ≤400 | ≤200 | ≤200 |

| Duty Cycle % | ≤40 | ≤40 | ≤20 | ≤20 |

| Bar pitch mm | 2 | 2 | 2.8 | 2.8 |

| Emitting Area mm | 10×11 | 10×19.5 | 10x20 | 10x25.5 |

| Operating Temp. ℃ | 15~35 | 15~35 | 15~35 | 15~35 |

| Storage Temp. ℃ | -10~50 | -10~50 | -10~50 | -10~50 |

| Flow Rate L/min | >4 | >4 | >4 | >4 |

Single-emitter laser diode (SE) chips are the basic built block for high-power and high-brightness semiconductor laser modules. We manufacture single chips with a variety of output powers and wavelengths.

| Part number | Wavelength, nm | Output power | Current/voltage | Emitting width, um | Divergence, deg | Size, um |

| STR-638A-110-1-1.5-SE | 638 | 1W | 1.4A/2.1V | 110 | 8/35 | 1500x400x150 |

| STR-755A-350-8-2.5-SE | 755 | 8W | 8A/1.9V | 350 | 9/38 | 2500x500x150 |

| STR-808A-150-3-1-SE | 808 | 3W | 3A/1.9V | 150 | 8/24 | 1000x500x150 |

| STR-808A-190-10-4-SE | 808 | 10W | 10A/1.8V | 190 | 10/38 | 4000x500x150 |

| STR-808A-350-10-2.5-SE | 808 | 10.5W | 10A/1.8V | 350 | 8/36 | 2500x500x150 |

| STR-880A-190-10-4-SE | 880 | 10W | 12A/1.8V | 190 | 8/32 | 2500x500x150 |

| STR-880A-350-10-2.5-SE | 880 | 9.8W | 10A/1.8V | 350 | 8/34 | 2500x500x150 |

| STR-905A-74-25-0.75-SE | 905 | 25W | 7A/7.2V | 74 | 13/30 | 750x400x150 |

| STR-905A-150-50-0.75-SE | 905 | 50W | 14A/7.6V | 150 | 12/31 | 750X400X150 |

| STR-905A-200-75-0.75-SE | 905 | 75W | 20A/8.4V | 200 | 12/30 | 750X400X150 |

| STR-905B-200-25-0.75-SE | 905 | 25W | 20A/3.8V | 200 | 14 | 750X600X150 |

| STR-905-38-15-0.75-SE | 905 | 15W | 5A/9.2V | 38 | 35/30 | 750X400X150 |

| STR-905C-70-25-0.75-SE | 905 | 25W | 8A/8.2V | 70 | 17/30 | 750X400X150 |

| STR-905C-300-75-0.75-SE | 905 | 75W | 22A/9.5V | 300 | 12/30 | 750x400x150 |

| STR-905D-300-100-0.75-SE | 905 | 100W | 22A/11V | 300 | 13/30 | 750x400x150 |

| STR-915A-96-12-4.8-SE | 915 | 12W | 12A/1.6V | 96 | 10/26 | 4800x500x150 |

| STR-915A-190-20-4-SE | 915 | 20W | 20A/1.7V | 190 | 10/26 | 4000x500x150 |

| STR-940A-96-12-4.8-SE | 940 | 12W | 12A/1.6V | 96 | 10/26 | 4800x500x150 |

| STR-940A-190-20-4-SE | 940 | 20W | 20A/1.7V | 190 | 10/26 | 4000x500x150 |

| STR-976A-96-10-4.8-SE | 976 | 10W | 10A/1.8V | 96 | 9/27 | 4800x500x150 |

| STR-976A-96-12-4.8-SE | 976 | 12W | 12A/1.6V | 96 | 10/26 | 4800x500x150 |

| STR-976A-96-13-4-SE | 976 | 13W | 12.5A/1.5V | 96 | 8/28 | 4000x500x150 |

| STR-976A-190-15-4-SE | 976 | 15.5W | 15A/1.6V | 190 | 10/29 | 4000x500x150 |

| STR-976A-190-20-4-SE | 976 | 20W | 20A/1.7V | 190 | 10/26 | 4000x500x150 |

| STR-1064A-190-10-4-SE | 1064 | 10W | 14A/0.9V | 190 | 10/30 | 4000x500x150 |

| STR-1064A-350-10-2.5-SE | 1064 | 10W | 13A/1.6V | 350 | 10/29 | 2500x500x150 |

| STR-1470A-96-1.5-1-SE | 1470 | 1.5W | 4A/1.4V | 96 | 11/31 | 1000x500x150 |

| STR-1470A-96-3-2-SE | 1470 | 3W | 9A/1.5V | 96 | 11/28 | 2000x500x150 |

| STR-1550A-96-1.5-1-SE | 1550 | 1.5W | 4A/1.4V | 96 | 11/31 | 1000x500x150 |

| STR-15500A-96-3-2-SE | 1550 | 3W | 9A/1.5V | 96 | 11/28 | 2000x500x150 |

Bare bar is an array of individual semiconductor laser chips, with combined output power from dozens of Watts to a few hundred Watts. Our proprietary facet passivation process ensures the reliability required by the most stringent applications.

In the following table, WL means wavelength, I/V means operation current/voltage, N means the numbers of emitters, P/width means period (um)/emitter width (um), L/W/T means length/width/thickness of the bar.

| Part number | WL nm | Mode | Power | I/V | N | P/Width um | Filling | L/W/T um |

| STR-755A-48-80-23-1.5-BAR | 755 | QCW | 80W | 86A/1.9V | 23 | 499/190 | 48% | 1500x10000x150 |

| STR-808A-30-50-19-1-BAR | 808 | CW | 50W | 45A/1.7V | 19 | 500/150 | 30% | 1000x98000x150 |

| STR-808A-48-100-23-1.5-BAR | 808 | CW | 100W | 88A/1.75V | 23 | 400/190 | 48% | 1500x9800x150 |

| STR-808A-72-300-34-1.5-BAR | 808 | QCW | 300W | 190A/1.85V | 34 | 290/210 | 72% | 1500x10000x150 |

| STR-940A-30-100-19-2-BAR | 940 | CW | 100W | 95A/1.65V | 19 | 500/150 | 30% | 2000x10000x150 |

| STR-940A-50-200-24-3-BAR | 940 | CW | 200W | 195A/1.63V | 24 | 400/200 | 50% | 3000x10200x150 |

| STR-940A-76-600-40-2-BAR | 940 | QCW | 600W | 600A/1.8V | 40 | 250/190 | 76% | 2000x10400x150 |

| STR-976A-10-35-5-4-BAR | 976 | CW | 35W | 35A/1.7V | 5 | 1000/100 | 10% | 4000x5000x150 |

| STR-1470A-18-8-6-2-BAR | 1470 | CW | 8W | 24A/1.4V | 6 | 400/96 | 18% | 2000x3000x150 |

High electrical-optical conversion efficiency

>20000 hours lifetime

Customized products available

Short lead time

Quick response

| Part number | Wavelength | Structure | Operation | Power | Operation current/voltage |

| STL-UMC-190-915-TE-18-4.0 | 915nm | Single chip | CW | 18W | 19.5A/1.8V |

| STL-UMC-95-915-TE-10-4.0 | 915nm | Single chip | CW | 10W | 11A/1.7V |

| STL-UMC-28-915-TE-0.5-0.5 | 915nm | Single chip | CW | 500mW | 0.55A/2V |

| STL-UMC-200-905-TE-75-1.0 | 905nm | Single chip | QCW | 75W | 30A/6.3V |

| STL-UMC-135-905-TE-50-1.0 | 905nm | Single chip | QCW | 50W | 23A/6.3V |

| STL-UMC-70-905-TE-25-1.0 | 905nm | Single chip | QCW | 25W | 10A/6.3V |

| STL-UMC-28-896-TE-0.5-1.0 | 896nm | Single chip | CW | 0.5W | 0.55A/1.8V |

| STL-UMC-200-880-TE-10-4.0 | 880nm | Single chip | CW | 10W | 10A/1.65V |

| STL-UMC-100-880-TE-6-4.0 | 880nm | Single chip | CW | 6W | 6.5A/1.65V |

| STL-UMC-47-830-TE-2.0-2.0 | 830nm | Single chip | CW | 2W | 2A/1.8V |

| STL-UMC-200-808-TE-10-4.0 | 808nm | Single chip | CW | 10W | 10A/1.75V |

| STL-UMC-390-808-TE-10-2.0 | 808nm | Single chip | CW | 10W | 10A/1.75V |

| STL-UMC-200-808-TE-8-4.0 | 808nm | Single chip | CW | 8W | 8.5A/1.75V |

| STL-UMC-200-808-TE-5-2.0 | 808nm | Single chip | CW | 5W | 4.8A/1.75V |

| STL-UMC-100-808-TE-3-2.0 | 808nm | Single chip | CW | 3W | 2.8A/1.75V |

| STL-UMC-100-785-TE-2-2.0 | 785nm | Single chip | CW | 2W | 2.2A/1.75V |

| STL-UMC-190-976-TE-20-4.0 | 976nm | Single chip | CW | 20W | 23A/1.8V |

| STL-UMC-95-976-TE-12-4.0-D2 | 976nm | single chip | CW | 12W | 13A/1.65V |

| STL-UMC-95-976-TE-12-4.0 | 980nm | Single chip | CW | 12W | 13A/1.75V |

| STL-UMC-190-940-TE-20-4.0 | 940nm | Single chip | CW | 20W | 23A/1.8V |

| STL-UMC-95-940-TE-12-4.0 | 940nm | Single chip | CW | 12W | 13A/1.75V |

| STL-UMC-390-808-TE-10-2.0 | 808nm | Single chip | CW | 10W | 10A/1.75V |

| STL-UMC-100-785-TE-2-2.0 | 785nm | Single chip | CW | 2W | 2.2A/1.75V |

| STL-UMB-10-5-976-TE-40-4.0 | 976nm | bar | CW | 40W | 41A/1.6 |

| STL-UMB-80-37-940-TE-1000-4.0 | 940nm | bar | QCW | 1000W | 550A/3.6V |

| STL-UMB-35-24-940-TE-200-3.0 | 940nm | bar | QCW | 200W | 212A/1.65V |

| STL-UMB-75-60-808-TE-500-1.5 | 808nm | bar | QCW | 500W | 460A/2.1V |

| STL-UMB-75-30-808-TE-150-1.5 | 808nm | bar | QCW | 150W | 145A/1.9V |

| STL-UMB-50-47-808-TE-100-1.5 | 808nm | bar | CW | 100W | 105A/1.8V |

| STL-UMB-50-47-808-TE-60-1.0 | 808nm | bar | CW | 60W | 63A/1.8V |

| STL-UMB-50-47-808-TE-100-1.5-2 | 808nm | bar | CW | 100W | 100A/1.8V |

| STL-UMB-75-30-808-TE-150-1.5 | 808nm | bar | QCW | 150W | 145A/1.9V |

| STL-UMB-75-60-808-TE-300-1.5 | 808nm | bar | QCW | 300W | 280A/1.9V |

| STL-UMB-75-60-808-TE-300-1.5-D1 | 808nm | bar | QCW | 300W | 280A/1.9V |

| STL-UMB-75-60-808-TE-200-1.0 | 808nm | bar | QCW | 200W | 190A/1.9V |

| STL-UMB-30-19-808-TE-50-1.0 | 808nm | bar | CW | 50W | 48.5A/1,8v |

Features:

High output power

High electrical-optical conversion efficiency

High brightness

High reliability

Technical Advantages:

High efficient epitaxial structure design

High-quality epitaxial material growth

Special passivation method for cavity surface

| Part number | Wavelength | Power | Operation current/voltage | Remark |

| STD-UMC-100-808-TE-6-4.0 | 808nm | 6W | 5.7A/1.75V | CW single chip |

| STD-UMC-190-808-TE-10-4.0 | 808nm | 10W | 9.5A/1,75 | CW single chip |

| STD-UMC-190-808-TE-12-4.0 | 808nm | 12W | 10.5A/1.75V | CW single chip |

| STD-UMC-100-915-TE-12-4.5 | 915nm | 12W | 10.5A/1.62V | CW single chip |

| STD-UMC-160-915-TE-18-5.0 | 915nm | 18W | 17.5A/1.65V | CW single chip |

| STD-UMC-190-915-TE-22-5.0 | 915nm | 22W | 20.0A/1.68V | CW single chip |

| STD-UMC-230-915-TE-25-5.0 | 915nm | 25W | 24.5A/1.70V | CW single chip |

| STD-UMC-100-945-TE-12-4.5 | 945nm | 12W | 11.5A/1.70V | CW single chip |

| STD-UMC-160-945-TE-18-5.0 | 945nm | 18W | 17.5A/1.70V | CW single chip |

| STD-UMC-190-945-TE-22-5.0 | 945nm | 22W | 21.5A/1.70V | CW single chip |

| STD-UMC-230-945-TE-25-5.0 | 945nm | 25W | 25.0A/1.70V | CW single chip |

| STD-UMC-100-975-TE-12-4.5 | 975nm | 12W | 12.5A/1.52V | CW single chip |

| STD-UMC-100-975-TE-15-4.5 | 975nm | 15W | 16.0A/1.55V | CW single chip |

| STD-UMC-190-975-TE-22-5.0 | 975nm | 22W | 23.5A/1.55V | CW single chip |

| STD-UMC-230-975-TE-25-5.0 | 975nm | 25W | 27.0A/1.55V | CW single chip |

| STD-UMC-230-975-TE-30-5.5 | 975nm | 30W | 33.0A/1.55V | CW single chip |

| STD-UMB-30-19-808-TE-50-1.5 | 808nm | 50W | 42.0A/1.80V | CW bar |

| STD-UMB-50-47-808-TE-100-1.5 | 808nm | 100W | 92.0A/1.80V | CW bar |

| STD-UMB-50-47-940-TE-120-2.0 | 940nm | 120W | 115A/1.65V | CW bar |

| STD-UMB-50-47-976-TE-200-4.0 | 976nm | 200W | 195A/1.55V | CW bar |

| STD-UMB-75-37-808-TE-300-1.5 | 808nm | 300W | 250A/2.00V | QCW bar |

AuSn hard solder packaging construction

High duty cycle, high energy density

Filtered water, alternative cooling fluids

Small pitch, compact size

Optional seal band optical waveguide assemble

Optional fast collimation

Used for laser pumping, hair removal etc.

| Part number | Structure | Laser power | Laser wavelength |

| STD-HS12 | Macro channel stack | 600W-16500W | 760nm-1100nm |

| STD-GS20 | Conduction cooling stack | 4000W-1000W | 760nm-1100nm |

| STD-L5 | Macro channel horizontal stack | 300W-3000W | 760nm-1100nm |

| STD-E27 | Macro channel stack | 4000W-10000W | 760nm-1100nm |

| STD-MA | Micro channel stack | 2500W-15000W | 760nm-1100nm |

| STD-HM7 | Whole micro channel stack | 700W-3500W | 760nm-1100nm |

AuSn hard solder packaging construction

High duty cycle, high energy density

Filtered water, alternative cooling fluids

Small pitch, compact size

Optional seal band optical waveguide assemble

Optional fast collimation

Used for laser pumping, hair removal etc.

| Wavelength | 760-1100nm | ||||

| Peak power, W | 600 | 1200 | 7200 | 10000 | 16500 |

| Operation mode | QCW | ||||

| Operation current, A | 50 | 95 | 550 | 450 | 450 |

| Duty cycle up to, % | 25 | 15 | 5 | 1 | 0.4 |

| Number of bars | 12 | 12 | 12 | 20 | Up to 33 |

| Bar to bar pitch, mm | 1.2 | 1.2 | 1.2 | 0.93 | 0.4 |

| Electric/optic conversion efficiency, % | 58 | Up to 60 | 56 | 56 | 56 |

| Fast axis divergence FWHM, deg | 35, optional FAC<4 | 35 | |||

| Slow axis divergence FWHM. deg | 10 | ||||

| Dimension, mm | 28.6x24x11.5mm | ||||

Typical pulse energy:

| Pulse width | Frequency (Hz) | Iop | |||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| 10 ms | 13 | 13 | 12.7 | 12.75 | 13 | 12.7 | 13 | 13 | 12.9 | 12.9 | 95A |

| 20 ms | 21 | 21 | 21.7 | 21.5 | 21.4 | 21.7 | 21 | 21.4 | 20 | 20.9 | 85A |

| 30 ms | 31 | 31.5 | 32 | 32 | - | - | - | - | - | - | 60A |

| 40 ms | 43 | 41 | 42 | - | - | - | - | - | - | - | 60A |

| 50 ms | 53 | 51 | - | - | - | - | - | - | - | - | - |

| 60 ms | 61 | 59.5 | - | - | - | - | - | - | - | - | - |

| 70 ms | 70 | - | - | - | - | - | - | - | - | - | - |

| 80 ms | 50 | - | - | - | - | - | - | - | - | - | - |

| 90 ms | 54 | - | - | - | - | - | - | - | - | - | - |

| 100ms | 60 | - | - | - | - | - | - | - | - | - | - |

Remark: cooling water: T 25deg, flow rate 4.5-5.0L/min

AuSn hard solder packaging construction

High power density

Optional fast-axis collimation

Small pitch, compact size

Optional seal protection

Multi-wavelength in a single array

Used for laser pumping, hair removal etc.

| Wavelength | 760-1100nm | ||

| Peak power, W | 4000 | 6000 | 10000 |

| Operation mode | QCW | QCW | QCW |

| Operation current, A | 200 | 280 | 450 |

| Duty cycle up to, % | 1.2 | 1 | 0.4 |

| Pulse width, us | Up to 1000 | 600 | 200 |

| Number of bars | 20 | ||

| Bar to bar pitch, mm | 0.73 | ||

| Electric/optic conversion efficiency, % | 52 | 56 | 58 |

| Fast axis divergence FWHM, deg | 35, optional FAC < 4 | ||

| Slow axis divergence FWHM. deg | 10 | ||

| Dimension, mm | 37.5x10x9 | ||

AuSn hard solder packaging construction

High power density

Contact size

Used for pumping

| Wavelength | 760-1100nm | ||

| Peak power, W | 300 | 1500 | 3000 |

| Operation mode | CW | QCW | QCW |

| Operation current, A | 55 | 280 | 550 |

| Number of bars | 5 | ||

| Bar to bar pitch, mm | 0.73 | ||

| Electric/optic conversion efficiency, % | 56 | 56 | 58 |

| Fast axis divergence FWHM, deg | 35 | ||

| Slow axis divergence FWHM. deg | 10 | ||

| Dimension, mm | 70x14x10 | ||

AuSn hard solder packaging construction

High power density

Optional fast axis collimation

Small pitch, compact size

Optional seal protection

Multi-wavelength in a single array

Used for laser pumping

| Wavelength | 760-1100nm | ||

| Peak power, W | 4000 | 6000 | 10000 |

| Operation mode | QCW | QCW | QCW |

| Operation current, A | 200 | 280 | 450 |

| Duty cycle up to, % | 8 | 5 | 0.4 |

| Pulse width, us | Up to 1000 | 600 | 200 |

| Number of bars | 20 | ||

| Bar to bar pitch, mm | 2.21 | ||

| Electric/optic conversion efficiency, % | 52 | 56 | 58 |

| Fast axis divergence FWHM, deg | 35, optional FAC < 4 | ||

| Slow axis divergence FWHM. deg | 10 | ||

| Dimension, mm | 37.5x12x13.4 | ||

AuSn hard solder packaging construction

High power density

Narrow spectrum

Filtered water, alternative cooling fluids

Used for laser pumping & hair removal

| Wavelength | 760-1100nm | ||

| Peak power, W | 700 | 2100 | 3500 |

| Operation mode | QCW | QCW | QCW |

| Operation current, A | 100 | 280 | 450 |

| Duty cycle up to, % | 40 | 8 | 4 |

| Pulse width, us | Up to 1000 | 600 | 200 |

| Number of bars | 7 | ||

| Bar to bar pitch, mm | 2.0 | ||

| Electric/optic conversion efficiency, % | 60 | 56 | 58 |

| Fast axis divergence FWHM, deg | 35 | ||

| Slow axis divergence FWHM. deg | 10 | ||

| Dimension, mm | 30x13x4.95 | ||

| Part number | Structure | Laser power | Laser wavelength |

| STD-HH05 | Macro channel stack | 300W/500W | 760nm-1100nm |

| STD-HL07 | Macro channel stack | 300W-700W | 760nm-1100nm |

| STD-HS12 | Macro channel stack | 600W-1200W | 760nm-1100nm |

AuSn hard solder packaging construction

Suitable for long pulse width operation

Filtered water, alternative cooling fluids

Seal protection

High duty cycle

Used for hair removal & laser pumping

Typical Specifications

| Wavelength | 760-1100nm | |

| Peak power, W | 300 | 500 |

| Operation mode | QCW | QCW |

| Operation current, A | 95 | 95 |

| Duty cycle up to, % | 20 | 10 |

| Pulse width, us | 200 | 100 |

| Number of bars | 3 | 5 |

| Bar to bar pitch, mm | 5 | 2.9 |

| Electric/optic conversion efficiency, % | 58 | 58 |

| Fast axis divergence FWHM, deg | 35 | |

| Slow axis divergence FWHM. deg | 10 | |

| Dimension, mm | 42x25.27x20 | |

Operation Conditions

| STD-HH05-808 | STD-HH03-300-808 | |||

| Peak power per bar, W | 100 | 80 | 60 | 100 |

| Operation current, A | 95 | 80 | 65 | 95 |

| Pulse width, ms | Max. frequency, Hz | |||

| 10 | 30 | 40 | 40 | 40 |

| 20 | 10 | 15 | 20 | 20 |

| 30 | 10 | 12 | 13 | 13 |

| 40 | 10 | 10 | 10 | 10 |

| 50 | 5 | 6 | 8 | 8 |

| 60 | 4 | 5 | 6 | 6 |

| 80 | 3 | 4 | 5 | 4 |

| 100 | 2 | 3 | 4 | 2 |

| 200 | - | 1 | 2 | 1 |

| 400 | - | - | 1 | - |

AuSn hard solder packaging construction

Suitable for long pulse width operation

Filtered water, alternative cooling fluids

Seal protection

High duty cycle

Used for hair removal & laser pumping

Typical Specifications

| Wavelength | 760-1100nm | |||

| Peak power, W | 300 | 500 | 600 | 700 |

| Operation mode | QCW | QCW | QCW | QCW |

| Operation current, A | 50 | 50 | 95 | 95 |

| Duty cycle up to, % | 40 | 40 | 10 | 10 |

| Pulse width, us | Up to 400 | Up to 400 | 100 | 100 |

| Number of bars | 60 | 10 | 6 | 7 |

| Bar to bar pitch, mm | 2.2 | 2.2 | 3.4 | 2.9 |

| Electric/optic conversion efficiency, % | 58 | 58 | 58 | 58 |

| Fast axis divergence FWHM, deg | 35 | |||

| Slow axis divergence FWHM. deg | 10 | |||

| Dimension, mm | 39x40x36 | |||

Operation Conditions

| STD-HL06-600-808 STD-HL07-700-808 | STD-HL06-300-808 STD-HL10-500-808 | |||

| Peak power per bar, W | 100 | 80 | 60 | 50 |

| Operation current, A | 95 | 80 | 65 | 50 |

| Pulse width, ms | Max. frequency, Hz | |||

| 10 | 30 | 40 | 40 | 440 |

| 20 | 10 | 15 | 20 | 20 |

| 30 | 10 | 12 | 13 | 13 |

| 40 | 10 | 10 | 10 | 10 |

| 50 | 5 | 6 | 8 | 8 |

| 60 | 4 | 5 | 6 | 6 |

| 80 | 3 | 4 | 5 | 5 |

| 100 | 2 | 3 | 4 | 4 |

| 200 | - | 1 | 2 | 2 |

| 400 | - | - | 1 | 1 |

AuSn hard solder packaging construction

High duty cycle, high energy density

Filtered water, alternative cooling fluids

Small pitch, compact size

Optional seal band optical waveguide assembly

Optional fast-axis collimation

Used for hair removal & laser pumping

| Wavelength | 760-1100nm | ||||

| Peak power, W | 600 | 1200 | 7200 | 10000 | 16500 |

| Operation mode | QCW | ||||

| Operation current, A | 50 | 95 | 550 | 450 | 450 |

| Duty cycle up to, % | 25 | 15 | 5 | 1 | 0.4 |

| Pulse width, us | 25 | 10 | 0.6 | 0.4 | 0.2 |

| Number of bars | 12 | 12 | 12 | 20 | Up to 33 |

| Bar to bar pitch, mm | 1.2 | 1.2 | 1.2 | 0.73 | 0.4 |

| Electric/optic conversion efficiency, % | 58 | Up to 60 | 56 | 56 | 56 |

| Fast axis divergence FWHM, deg | 35, optional FAC<4 | 35 | |||

| Slow axis divergence FWHM. deg | 10 | ||||

| Dimension, mm | 28.6x24x11.5mm | ||||

STD-HS12-1200-808 typical pulse energy (J/cm2):

| Pulse width | Frequency (Hz) | Iop | |||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| 10 ms | 13 | 13 | 12.7 | 12.75 | 13 | 12.7 | 13 | 13 | 12.9 | 12.9 | 95A |

| 20 ms | 21 | 21 | 21.7 | 21.5 | 21.4 | 21.7 | 21 | 21.4 | 20 | 20.9 | 85A |

| 30 ms | 31 | 31.5 | 32 | 32 | - | - | - | - | - | - | 60A |

| 40 ms | 43 | 41 | 42 | - | - | - | - | - | - | - | 60A |

| 50 ms | 53 | 51 | - | - | - | - | - | - | - | - | - |

| 60 ms | 61 | 59.5 | - | - | - | - | - | - | - | - | - |

| 70 ms | 70 | - | - | - | - | - | - | - | - | - | - |

| 80 ms | 50 | - | - | - | - | - | - | - | - | - | - |

| 90 ms | 54 | - | - | - | - | - | - | - | - | - | - |

| 100ms | 60 | - | - | - | - | - | - | - | - | - | - |

Remark: cooling water: T 25deg, flow rate 4.5-5.0L/min

| Model | STO-CS20 | STO-CS40 | STO-CS60 | STO-CS100Q | STO-CS200Q | STO-CS300Q |

| Output Power | 20W | 40W | 60W | 100W | 200W | 300W |

| Wavelength | 808 / 880 / 915 / 976 / 980 nm | 808 / 880 / 915 / 976 / 980 nm | 808 / 880 / 915 / 976 / 980 nm | 808 / 880 / 915 / 976 / 980 nm | 808 / 880 / 915 / 976 / 980 nm | 808 / 880 / 915 / 976 / 980 nm |

| Operation Mode | CW | CW | CW | QCW | QCW | QCW |

| Duty Circle | CW | CW | CW | ≤5% | ≤5% | ≤5% |

| Pulse Width | CW | CW | CW | ≤300μs | ≤300μs | ≤300μs |

| Typical Current | 25A | 40A | 60A | 100A | 180A | 260A |

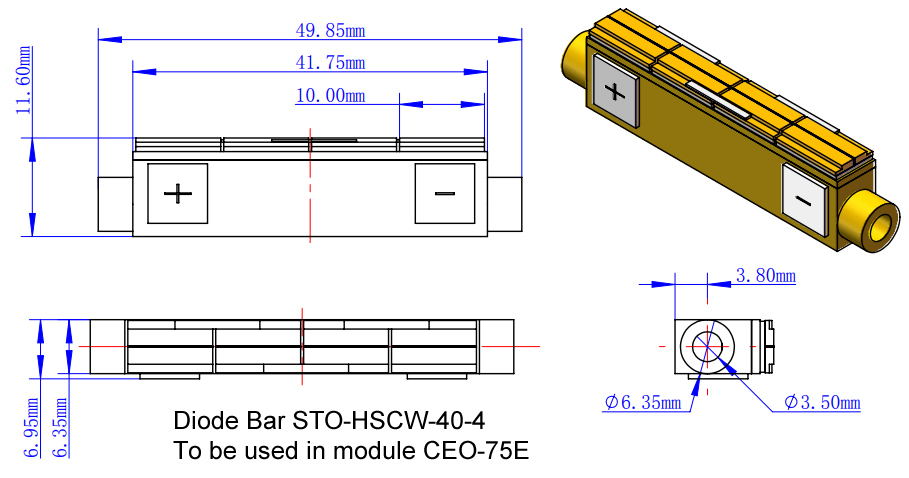

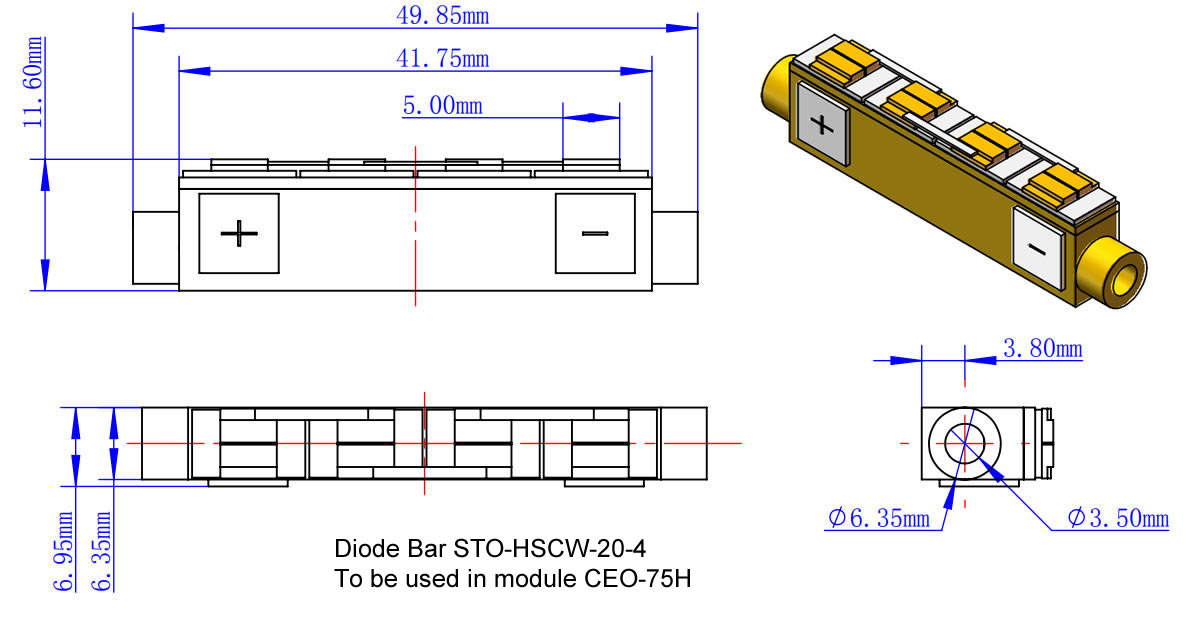

STO-HSCW Series, CW Laser Diode Horizontal Stacks

| Model | STO-HSCW-20-3 | STO-HSCW-20-4 | STO-HSCW-40-3 | STO-HSCW-40-4 |

| Output Power | 60W | 80W | 120W | 160W |

| Typical Current | 25A | 25A | 38A | 38A |

| Operation Voltage | <6V | <8V | <6V | <8V |

Note: STO-HSCW-20/40-N can be customized with N≤20. The total output power is 20/40 times N.

STOU-HSQCW Series QCW Laser Diode Horizontal Stacks

| Model | STO-HSQCW-100~300-N |

| Output Power | QCW 100W~300W*N |

| Repetition Rate | 0-1000Hz |

| Pulse Width | 50-300μs |

| Duty Circle | ≤10% or ≤20% |

Note: STO-HSQCW-100~300-N can be customized. Single unit can be mounted with 1, 2 or 3 pcs of laser diode bar. Typical wavelength of the diode bar is 805+/-3nm. However, the wavelength must be specified according to the special pulse width, repetition rate and heat sink designs.

Specifications of Diode Bar STO-HSCW-40-4

Output power (W): 80W

Center Wavelength at 25 °C (nm): 808±3

Power per bar (W): 40

Number of bars in one stack(N): 4

Working mode: CW

Operation Current (A): ≤22

Operating Voltage (V): ≤8

Cooling: water

Bar arrangement: linear 4bars

Operation Temperature(°C): 25±1

Applications: to be used in the diode pump laser module CEO-75E

Specifications of Diode Bar STO-HSCW-20-4:

Output power (W): 80W

Center Wavelength at 25 °C (nm): 808±3

Power per bar (W): 20

Number of bars in one stack(N): 4

Working mode: CW

Operation Current (A): £18

Operating Voltage (V): £8

Cooling: water

Bar arrangement: linear 4bars

Operation Temperature(°C): 25±1

Applications: to be used in the diode pump laser module CEO-75H

| STO-VSQCW-MI/MA-100~300-N | STO-VSCW-MI/MA-40~100-N | |

| Single Bar Power | 100W,150W,200W,300W QCW | 40W,60W,100W CW |

| Bar Total / Stack | N=1~20 | N=1~20 |

| Bar Pitch | 0.5mm~2mm | 1.8mm |

| Wavelength | 808nm | 808nm |

Note: STO-VSQCW/CW-MI/MA-100~300-N can be customized. We provide micro channel water cooling technology and high reliability macro channel water cooling technology. Typical wavelength of the diode bar is 808+/-3nm. However, the wavelength must be specified according to the special pulse width, repetition rate and heat sink designs.

We make the QCW laser into an arc, which is beneficial to the lightweight design of the pump structure. Au-Sn packaging technology makes the laser have high reliability even in harsh working environment.

Feature

Wavelength: 808nm or up on requirement

Output power: 500 - 4800W

Operation mode: QCW

Cooling: actively cooled / passively cooled

Benefits

Efficient:High output power up into the 4800W.

Compact:Arc and lightweight design are easily integrated into pump module.

Robust:Shock and vibration resistant.

Reliable and high-quality: Gold and Tin (hard solder) mounting. Works even under the most demanding climatic conditions.

Wavelength combination: beneficial for full temperature pumping design.

Application

High energy research: QCW pumping sources for solid-state lasers.

Medical technology: Long-pulse operation, use in esthetics (epilation) and dermatology.

Excitation light source for solid-state lasers in the 1320 nm range for parenchyma surgery.

Defense: Short-pulse operation, use as a pumping source, for lighting or in LIDAR systems.

Industry: pump source for solid-state and fiber lasers.

| Model | STO-ARCQCW-MA-100~500-N |

| Optical parameters | |

| Output power (W) | QCW 100~500*N |

| Center wavelength at 25 °C (nm) | 808 |

| Number of bars in one stack | 1~20 |

| Bar pitch (mm) | 0.8~3 |

| Center wavelength variation at 25 °C (nm) | ±3/±10 |

| Typical spectral bandwidth (FWHM) | <3 |

| Divergence (degree) (FWHM) | <39⊥<10‖ |

| Polarization | TE |

| Wavelength shift (nm/℃) | ~0.28 |

| Electrical parameters | |

| Working mode | QCW |

| Maximum duty cycle (%) | £2% |

| Pulse length (us) | 50~1000 |

| Frequency (Hz) | 1~1000 |

| Operation current (A) | <=100~500 |

| Operating voltage (V) | <=2*N |

| Typical slope (W/A) | >1.1 |

| Electro-optic conversion efficiency (%) | >50 |

| Thermal parameters | |

| Operation temperature (℃) | -40~60 |

| Storage temperature (℃) | -50~85 |

| Storage humidity (%) | <70 |

| Cooling | TEC/air cooling |

Note:

STO-ARCQCW-MA-100~500-N represent N*100-500W laser stack which is mounted on an arc heatsink. The laser power of single bar is 100W, 200W, 300W or 500W.

The wavelengths of each bar in a single device can be arranged and combined according to the heat dissipation conditions.

The above parameters are measured at the heat sink temperature of 25oC.

Heat sink structure can be customized according to customer's special requirements

The QCW laser is made into a ring, which improves the uniformity of the pump while making use of the lightweight design of the pump structure. Au-Sn packaging technology makes the laser have high reliability even in harsh working environment.

Feature

Wavelength: 808nm or up on request

Output power: 500W up to 10kW

Operation mode: QCW

Cooling: actively cooled / passively cooled

Benefits

Efficient: High output power up to 4800W.

Compact: Arc and lightweight design is easily integrated into pump module.

Robust: Shock and vibration resistant.

Reliable and high-quality: Gold and Tin (hard solder) mounting. Works even under the most demanding climatic conditions.

Wavelength combination: beneficial for full temperature pumping design.

Application

High energy research: QCW pumping sources for solid-state lasers.

Medical technology: Long-pulse operation, use in esthetics (epilation) and dermatology.

Pump source for solid-state lasers in the 1320nm range for parenchyma surgery.

Defense: Short-pulse operation, use as a pumping source, for lighting or in LIDAR systems.

Industry: Pump source for solid-state and fiber lasers.

| Model | STO-ARCQCW-MA-100~500-N |

| Optical parameters | |

| Output power(W) | QCW 100~500*N |

| Center wavelength at 25 °C(nm) | 808 |

| Number of bars in one stack | 1~40 |

| Bar pitch(mm) | 0.8~3 |

| Center wavelength variation at 25 °C(nm) | ±3/±10 |

| Typical spectral bandwidth (FWHM) | <3 |

| Divergence(degree)(FWHM) | <39⊥<10‖ |

| Polarization | TE |

| Wavelength shift(nm/℃) | ~0.28 |

| Electrical parameters | |

| Working mode | QCW |

| Maximum duty cycle(%) | £2% |

| Pulse length(us) | 50~1000 |

| Frequency(Hz) | 1~1000 |

| Operation current(A) | <=100~500 |

| Operating voltage(V) | <=2*N |

| Typical slope(W/A) | >1.1 |

| Electro-optic conversion efficiency(%) | >50 |

| Thermal parameters | |

| Operation temperature(℃) | -40~60 |

| Storage temperature(℃) | -50~85 |

| Storage humidity(%) | <70 |

| Cooling | passively cooled/actively cooled |

| Flow rate per bar(L/min) | 0.3-0.8 |

Note:

STO-ARCQCW-MA-100~500-N represents N*100-500W laser stack which is mounted on an annular heatsink. The laser power of single bar is 100W, 200W, 300W or 500W.

The wavelengths of each bar in a single device can be arranged and combined according to the heat dissipation conditions.

The above parameters are measured at the heat sink temperature of 25oC.

Heat sink structure can be customized according to customer's special requirements

The duty cycle is usually less than 2%. In case of special high duty cycle requirements, the laser structure can be customized. Then duty circle up to 20%.

We use Gold and Tin to assemble our vertical QCW stacks. This technology makes the laser have high reliability even in harsh working environment.

Feature

Wavelength: 808nm or up on request

Output power: 500W up to 10kW

Operation mode: QCW

Cooling: actively cooled / passively cooled

FAC available

Benefits

Customized upon request to adjust pumping structure.

Robust: Shock and vibration resistant.

Reliable and high-quality: Gold and Tin (hard solder) mounting. Works even under the most demanding climatic conditions.

Wavelength combination: beneficial for full temperature pumping design.

Duty circle up to 20%.

Application

High energy research: QCW pumping sources for solid-state lasers.

Medical technology: Long-pulse operation, use in esthetics (epilation) and dermatology.

Pump source for solid-state lasers in the 1320 nm range for parenchyma surgery.

Defense: Short-pulse operation, used as a pumping source, for lighting or in LIDAR systems.

Industry: Pump source for solid-state and fiber lasers.

| Model | STO-VSQCW-MI-MA-100~500-N | STO-VSQCW-MI-MA-100~500-N-FAC |

| Optical parameters | ||

| Output power(W) | QCW 100~500*N | |

| Output power after collimation(W) | 90~450*N | |

| Center wavelength at 25 °C(nm) | 808 | 808 |

| Number of bars in one stack | 1~20 | 1~20 |

| Bar pitch(mm) | 0.8~3 | 0.8~3 |

| Center wavelength variation at 25 °C(nm) | ±3/±10 | ±3/±10 |

| Typical spectral bandwidth (FWHM) | <3 | <3 |

| Typical fast axis divergence 95 %(°) | 66 | |

| Typical slow axis divergence 95 %(°) | 10 | 10 |

| Fast axis divergence (full power)(°) | <0.5 | |

| Polarization | TE | TE |

| Wavelength shift(nm/℃) | ~0.28 | ~0.28 |

| Electrical parameters | ||

| Working mode | QCW | QCW |

| Maximum duty cycle(%) | £20% | £20% |

| Pulse length(us) | 50~1000 | 50~1000 |

| Frequency(Hz) | 1~1000 | 1~1000 |

| Operation current(A) | <=100~500 | <=100~500 |

| Operating voltage(V) | <=2*N | <=2*N |

| Typical slope(W/A) | >1.1 | >1.1 |

| Electro-optic conversion efficiency(%) | >50 | >50 |

| Thermal parameters | ||

| Operation temperature(℃) | -40~60 | -40~60 |

| Storage temperature(℃) | -50~85 | -50~85 |

| Storage humidity(%) | <70 | <70 |

| Cooling | passively cooled/actively cooled | passively cooled/actively cooled |

| Flow rate per bar(L/min) | 0.3-0.8 | 0.3-0.8 |

Note:

STO-VSQCW-MI/MA-100~500-N. MI means micro channel cooler as a heatsink which needs deionized water. MA means passively cooled or pure water cooled heatsink.

STO-VSQCW-MI/MA-100~500-N. 100~500 represents that the laser power per bar can be 100W, 200W, 300W or 500W.

The above parameters are measured at the heat sink temperature of 25oC.

The wavelengths of each bar in a single device can be arranged and combined according to the heat dissipation conditions.

Heat sink structure can be customized according to customer's special requirements

Our vertical stacks can be used to increase the optical output power of your diode lasers To do so, we stack up to 12 mounted laser bars to form a diode laser stack or an assembly. Each of these laser bars individually supplies up to 100W in CW mode. Because of the small gaps between the laser bars, you obtain maximum brightness from the stacks, enabling you to work highly effectively. You can choose between laser diode stacks with a fast-axis (FA) or without collimation.

Feature

High optical output power of 100W CW per bar

Wavelength: 808 nm ±3nm

High efficiency, low divergence

Lifetime >10,000 hours, high reliability

Collimation: fast axis / without

Application

Material processing

Medical technology

Pumping source for fiber lasers and solid-state lasers.

| Model | STO-VSCW-MI-40~100-N | STO-VSCW-MI-40~100-N-FAC |

| Optical parameters | ||

| Output power(W) | CW 40~100*N | |

| Output power after collimation(W) | 36~90*N | |

| Center wavelength at 25 °C(nm) | 808 | 808 |

| Number of bars in one stack | 1~12 | 1~12 |

| Bar pitch(mm) | 1.8/0.8~3 | 1.8/0.8~3 |

| Center wavelength variation at 25 °C (nm) | ±3/±10 | ±3/±10 |

| Typical spectral bandwidth (FWHM) | <3 | <3 |

| Typical fast axis divergence 95 %(°) | 66 | |

| Typical slow axis divergence 95 %(°) | 10 | 10 |

| Fast axis divergence (full power)(°) | <0.5 | |

| Polarization | TE | TE |

| Wavelength shift(nm/℃) | ~0.28 | ~0.28 |

| Electrical parameters | ||

| Operation current(A) | <=40~100 | <=40~100 |

| Operating voltage(V) | <=2*N | <=2*N |

| Typical slope(W/A) | >1.1 | >1.1 |

| Electro-optic conversion efficiency(%) | >50 | >50 |

| Thermal parameters | ||

| Operation temperature(℃) | 20~30 | 20~30 |

| Storage temperature(℃) | 0~55 | 0~55 |

| Storage humidity(%) | <70 | <70 |

| Cooling | deionized water | deionized water |

| Flow rate per bar(L/min) | 0.3-0.8 | 0.3-0.8 |

Note:

STO-VSCW-MI-40~100-N. MI represents we use micro channel cooler as a heatsink which needs deionized water.

STO-VSCW-MI-40~100-N. 40~100 represents the laser power per bar can be 40W, 60W or 100W. 100W bar only can be used in cosmetic applications.

We supply various diode stacks for laser hair removal. These stacks can custom-designed and –made according to your specific requirements.

| Model No. | STO-VS-Ml-100-N |

| Application | Laser hair removal handpiece |

| Operation mode | CW |

| Bar numbers in one stack | N=1-20 bars |

| Power per sub-mounts | 100W |

| Central wavelength at 25℃ | 810nm/755nm/1064nm |

| Typical Operation current | 90A |

| Maximum Operation current | 100A |

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 18 South Liu Fang Yuan Road, Sintec Industrial Park, Optics Valley of China, Wuhan Hubei, 430205 PR China

Mobile/Wechat: +86 19913132317

Whatsapp: +86 19913132317

E-mail: sales@SintecOptronics.cn