High precision 3-dimensional 5-axis small size metal laser cutting machine combines with many years of experience of producting laser equipments and accumualation of using cases in automitive industry. The main part refer to CNC design concept, has compact structure,high stability,can realize high precision stable cutting. Equipped with gantry, th m laser machine can realize dual driving.

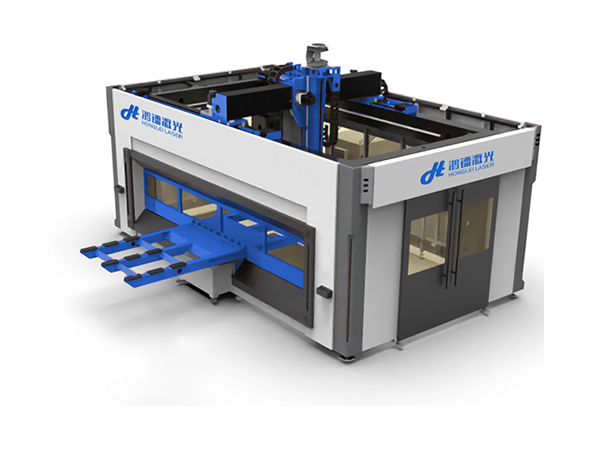

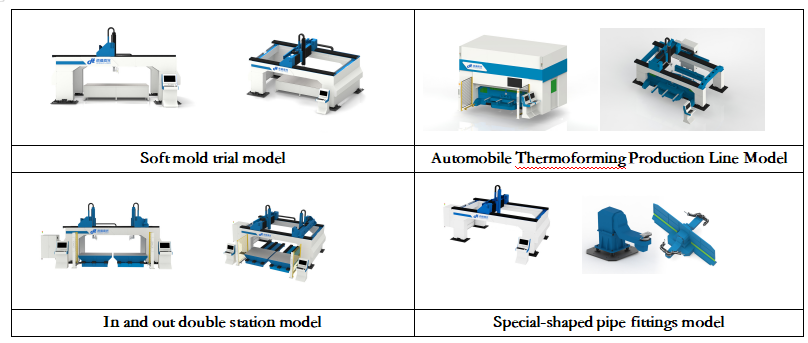

The High precision 3-dimensional 5-axis small size metal laser cutting machine is a new machine that Sintec independently researches and develops combine with many years of experience of producing laser equipment and accumulation of application cases in automotive industry.The main part refer to CNC machine design concept, compact structure,high stability,can realize high precision stable cutting. The gantry is double-drive structure, the worktable adopts a beam which is formed by integrated welding and has high-rigidity, high-dynamic response and a dedicated guide rail base, double-sided gear rack and double motor driver for linear guides, and a fully enclosed hard optical path to ensure the cleanliness and dust-freeness of the optical path system; it is standardly equipped with n×360° rotating three-dimensional cutting head and ±125° swing, which can realize free switching between three-dimensional and plane cutting, the CNC system with a good human-machine interface can control six axes (XYZACB axes) in real time; it can also control peripheral equipment such as lasers, fixtures, turntables, safety protection, etc. in real time to achieve remote monitoring and diagnosis. The machine tool safety protection complies with CE international safety standards. The whole machine has completely independent intellectual property rights, and all major core components are domestically produced, breaking the core monopoly of foreign companies on three-dimensional five-axis laser cutting machines.The processing format has two specifications: 3m×1.5m and 4m×2.2m. Other formats can be customized. The workbench can be selected according to customer needs, such as rotary, translational or fixed workbench, and can be applied to a wide range of applications. It mainly solves the hole cutting and trimming problems of automotive high-strength steel hot-formed parts, and meets the beat requirements of the automotive industry.Cutting with this equipment is economical and efficient, long-term stable and has excellent processing quality. It can be customized according to production needs, greatly shortening the new product development cycle and reducing manufacturing costs.Laser replaces traditional punching and shearing processing methods, reducing mold investment, and has a high cost-effectiveness. The investment in new product development is 30% of punching and shearing, and the processing cost is 10% of punching and shearing. The cutting speed and efficiency are more than 3 to 5 times that of robots, which greatly shortens the development cycle of automobile manufacturers and parts suppliers, improves processing efficiency and workpiece accuracy, and reduces production costs.

1. Highly stable mechanical structure: The gantry dual-drive structure is designed and installed, and the steel bed is welded to ensure the excellent rigidity and stability of the overall equipment;

2. First-class dynamic performance: The X-axis adopts imported brand dual-motor servo synchronous drive, and the Z-axis adopts aviation cast aluminum material to ensure that the equipment can run stably at high speed and high precision;

3. Intelligent CNC system: The system has super computing power, a clear human-computer interaction interface and a powerful expert laser process database, making the generation and debugging of cutting programs simple and convenient;

4. Excellent cutting technology: thanks to the n×360° rotating three-dimensional cutting head, it has super high dynamic performance and running accuracy, ensuring high-quality cutting;

5. Higher capacity mass production: equipped with a rotating worktable to achieve semi-automation, which can maximize processing efficiency and shorten production cycle;

6. Compact structure saves space: the equipment has a compact structure, optimized layout, and very small footprint, and multiple equipment can be arranged according to the production workshop;

7. Green, environmentally friendly, safe and reliable: green, environmentally friendly and safe design concept, fully enclosed machine tool cover, double grating protection, protective doors are all with interlocking protection, video monitoring machine tools, to ensure human and machine safety;

8. Completely localized, breaking through foreign technology blockades, with independent intellectual property rights, can be customized according to more sustainable needs.

X-axis travel | standard:3000m,Optional: 4000 mm ~6000 mm |

Y-axis travel | standard:1500mm,Optional:2000mm ~ 2500 mm |

Z-axis travel | standard:650mm,Optional: 750mm ~ 800mm |

A-axis travel(swing axis) | ±125° |

C-axis travel(rotating axis) | ±360° |

Follower axis travel (floating axis) | ±13.5mm |

X/Y/Z axis maximum speed | 100/100/100m/min |

X/Y/Z axis comprehensive speed | 173 m/min |

A/CX/Y/Z axis maximum speed | 90r/min |

X/Y/Z axis maximum acceleration | 1.0G |

A/C axis maximum acceleration | 200rad/s2 |

X/Y/Z axis positioning accuracy | ±0.03mm |

X/Y/Z axis repeat positioning accuracy | ±0.02mm |

A/C axis positioning accuracy | ±0.015° |

A/C axis repeat positioning accuracy | ±0.005° |

Turntable load(one side) | 500KG |

Turntable rotation radius | 4200mm |

Fastest rotation time of turntable | 2.5s |

Maximum laser power | 6000W |

Power parameters | Three-phase 380V/ 50Hz |

Total power protection level | IP54 |

Machine weight | standard:≈20 T |

Floor space dimensions (length x width x height) | standard:6600×6400×3970mm,optional:6600×7100×3970mm,6750×5300×4300mm,8250×5300×4300mm |

Widely used in automobile manufacturing, mold manufacturing, engineering machinery manufacturing, elevator manufacturing, home appliance manufacturing, medical equipment and other industries, such as automobile hot forming parts, 3D metal forming parts, curved parts, special-shaped pipes and three-dimensional precision high-speed cutting (hole cutting, edge cutting) for other metal materials

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 18 South Liu Fang Yuan Road, Sintec Industrial Park, Optics Valley of China, Wuhan Hubei, 430205 PR China

Mobile/Wechat: +86 19913132317

Whatsapp: +86 19913132317

E-mail: sales@SintecOptronics.cn