From Stamping to Laser: How Flexible Cutting Works Like Transformers?

Changing production lines used to be like rerailing trains – now laser cutting lets tracks reshape themselves. Discover how this "shape-shifting" tech boosts efficiency by 90%.

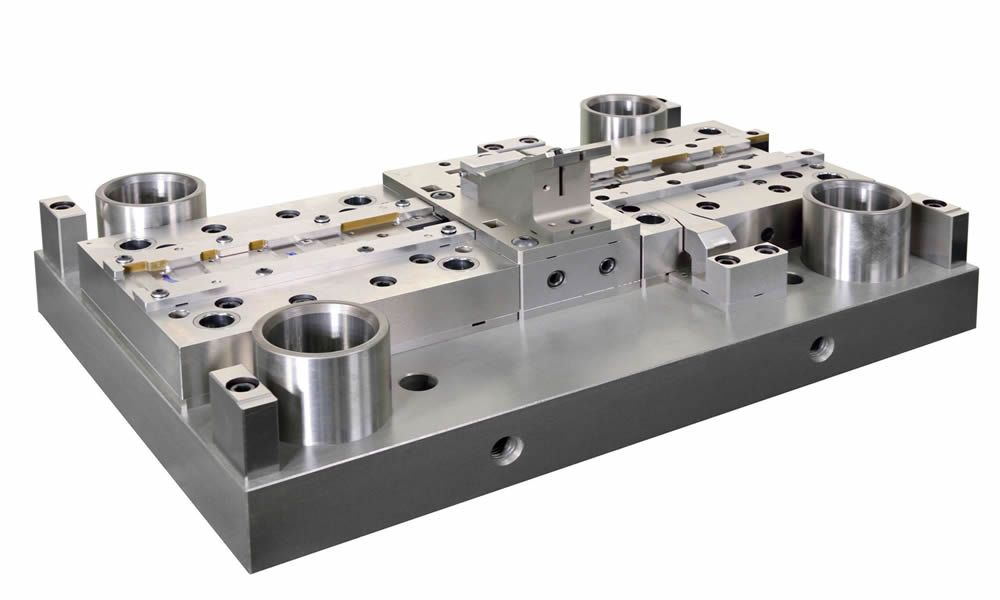

1. The "Mold Prison" of Stamping

Scene (Mexican Auto Parts Plant):

Changeover Nightmare:

8AM: New EV battery tray order received

10AM: Locate 3-ton mold in warehouse

2PM: Crane setup with 3mm error

Result: $8,000 daily loss

Global Pain (BCG Data):

1 mold = 1 Tesla Model 3 ($35k)

Annual changeover time = 1.5 NBA seasons

Mold storage = 2 basketball courts

2. Laser's Shape-Shifting Magic

Core Tech Explained:

Smart Focus:

Works like smartphone face ID – adapts to material in 0.1s

AI Vision:

Process: Snap photo → AI recognition → Cutting path ready (faster than coffee break)

Robotic Dance:

6-axis arm + rotary table = metalworking ballerina

Mexico result: 153 products from phone holders to truck parts

3. Global Factory Makeovers

Factory | Traditional | Laser | Savings |

German Stamp | 2 changeovers/day | 22 changeovers/day | Saved Christmas vacation |

Indian Supplier | 2000㎡ mold storage | Converted to gym | Space for 20 trucks |

Chinese EV Maker | 3-day urgent response | 3-hour new part launch | 1-year market lead |

4. 3-Step Transformation

1) Upload Designs: Easy as food delivery apps

2) Smart Scheduling: AI outsmarts veteran managers

3) Global Monitoring: Check production from Maldives beach

User Testimonial:

"Changing molds used to be heart surgery – now it's like changing phone wallpapers!" – Toyota Mexico Manager

For more further information, pls click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்