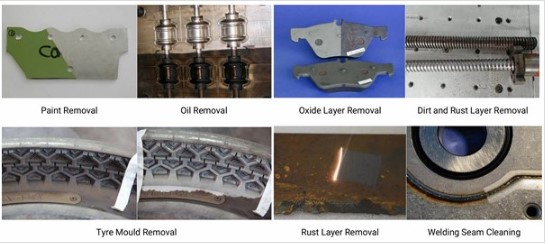

SXM Series Laser Cleaning MachinesOur laser cleaning machines are mainly used for cleaning various metal surfaces with localized rust, paint, coatings, oil stains, oxide films, and other pollutants. It can also be used for cleaning the surfaces of non-metallic substrates such as ceramics, glass, and

Our laser cleaning machines are mainly used for cleaning various metal surfaces with localized rust, paint, coatings, oil stains, oxide films, and other pollutants. It can also be used for cleaning the surfaces of non-metallic substrates such as ceramics, glass, and composite materials. Typical applications include cleaning of natural oxide film on aluminum alloy before welding, cleaning of black and gray oxide on battery trays after welding, cleaning of welds on train bogies before non-destructive testing, cleaning of automotive sheet metal parts before refurbishment, and cleaning of parts of steel components such as small holes and grooves that cannot be reached by wire brushes.

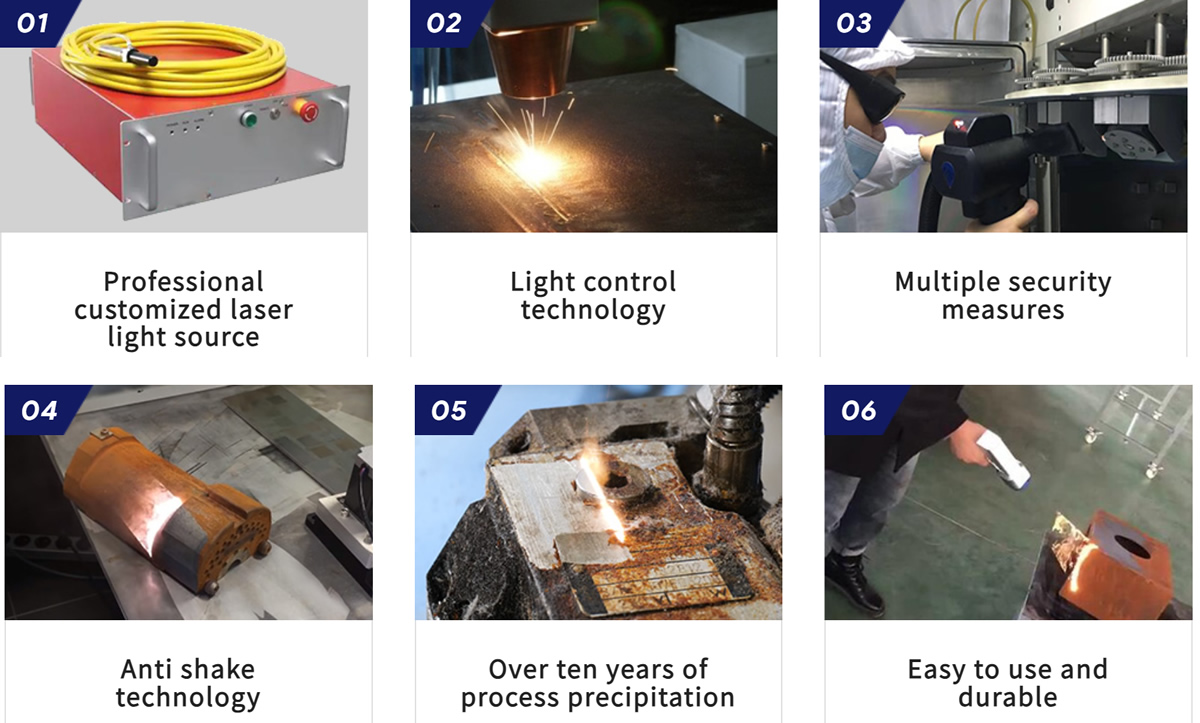

Product Advantages:

Product Specifications:

Part number | SXM-H-100W | SXM-H-200W SXM-H-300W | SXM-H-500W SXM-H-1000W |

Laser power | 100W | 200W/300W | 500W/1000W |

Machine weight | 22kg | 60kg | 180kg |

Cleaning head weight | 1.3kg | 1.3kg | 4.5kg (single mode) 2kg (multiple mode) |

Fiber length | 5m | 5m | 10m |

External dimensions | 603*258*481mm | 783*300*784mm | 913*573*881mm |

Cooling method; | Air cooling | Air cooling | Water cooling |

Laser wavelength | 1064nm | 1064nm | 1064nm |

Pulse energy | Max. 1.5mJ | Max. 1.5mJ (single mode), 5mJ | |

Scanning width | 5-150mm adjustable | 5-100mm adjustable | 5-150mm adjustable |

Power consumption @25℃ | <500W | <1000W/<1500W | <4000W/<6000W |

Supply gas pressure | 0.4MPa clean air | 0.4MPa clean air | 0.4MPa clean air |

Cleaned Samples:

The high-power CW laser cleaning machines are mainly used in such as rust removal of steel structures, rust removal of steel plates, rust removal of ships, paint removal of steel structures, paint removal of ships and components, oil removal, etc. Suitable for the refurbishment of marine vessel components, rail transit components, steel structure rust removal, steel structure refurbishment, etc.

Part number | SXM-CW-H-1000W SXM-CW-H-1500W SXM-CW-H-2000W | SXM-CW-H-3000W |

Laser power | 1000/1500/200W | 3000W |

Machine weight | 170kg | 220kg |

Cleaning head weight | Lightweight cleaning head | 1.5kg |

Fiber length | 10m | 10m |

External dimensions | 980*420*712mm | 1264*779*1287mm |

Cooling method; | Internal water circulation | Internal water circulation |

Laser wavelength | 1080nm | 1080nm |

Scanning width | 5-150mm adjustable | 5-150mm adjustable |

Our laser cleaning machine is a new generation product that is used for the purpose of material surface cleaning applications. It can be easily set up, operated and automated to remove surface dirt layers, which can be rust, grease, paint, primer, etc. Precise cleaning of specific areas and selective cleaning of selective dirt layers can be achieved by optimising beam parameters. Minimal consumables are required for the cleaning process – only electricity to power the equipment and water for the chiller – meaning the process is environmentally friendly and low in operating costs.

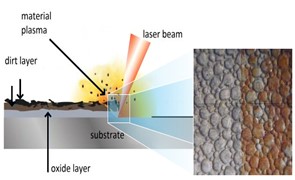

Principle:

Use of a high-power-density laser beam. When the laser beam contacts a surface, light/heat is absorbed by the surface.

Upon hitting the ablation threshold, molecular bonds in the surface are broken and ejected from the substrate (“vaporized”)

The dirt layer usually has a lower ablation threshold than the substrate material. As such, it will vaporize earlier, with little damage caused to the substrate layer.

Advantages:

Non-contact cleaning, little damage to the base substrate layer.

Precise cleaning: Able to clean specific areas using pre-defined beam parameters.

Selective cleaning: Able to remove different dirt layers individually based on the ablation threshold.

High cleaning efficiency.

Stable and compact design, with minimal maintenance efforts.

Easy to operate by operator or integrated with a robotic arm for automated cleaning.

No need to use chemicals, dry ice or other cleaning mediums. Few consumables, safe and environmentally friendly.

Sample Applications:

Parameter | STX-QX100 | STX-QX200 | STX-QX300 | STX-QX500 |

Ave. Laser Power (W) | 100 | 200 | 300 | 500 |

Wavelength | 1064 +/-5nm | |||

Pulse Frequency (kHz) | 20-200 | 10-50 | 20-50 | 20-50 |

Cable Length (m) | 3 | 5 | 5 | 10 |

Cooling Method | Air-Cooled | Water-Cooled | Water-Cooled | Water-Cooled |

Beam Width (mm) | 10-10 | |||

Speed (mm/s) | 1000-8000 | |||

Cleaning Head Weight (kg) | 3 | |||

Total Power (W) | 1000 | 2700 | 3900 | 4700 |

Machine Weight (kg) | 125 | 200 | 200 | 240 |

Operating Voltage | Single phase 220VAC/50-60Hz | |||

Parameter | STX-CW1500W | STX-CW2000W | STX-CW3000W |

Laser Power (W) | 1500 | 2000 | 3000 |

Modulation Frequency (Hz) | 1 – 20,000 | ||

Wavelength (nm) | 1080 +/- 5 | ||

Cooling Method | Water-cooled | ||

Power Required | 220V±20%/AC/50Hz | 380V±20%/AC/50Hz | 380V±20%/AC/50Hz |

Power Consumption (kW, per hr) | 7 | 9.5 | 13.3 |

Fiber Length (m) | 8 | ||

Fiber Core Diameter (um) | 50 | ||

Cleaning Head Weight (kg) | < 1 | ||

Beam Width (mm) | Up to 300 | ||

Machine Dimensions (mm) | 1000 x 530 x 725 | 1000 x 530 x 725 | 1120 x 580 x 1020 |

Machine Net Weight (kg) | Up to 150 | ||

1. 200W/300W Cart Laser Cleaning Machine

Product Introduction

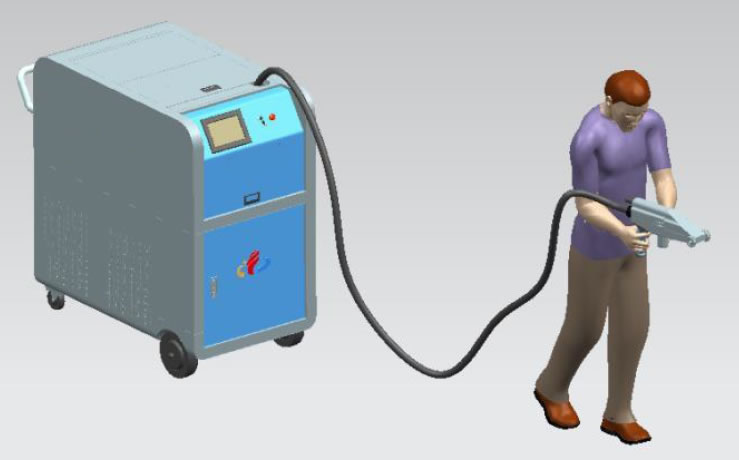

l Cart design ,easy to move

l Pulse fiber laser: 200W/300W water cooling

l Voltage of the power supply: 220VAC

l Cabinet integrated with chiller & dust extractor

l Top hat beam profile

Advantages

l Cart cabinet: equipped with wheels and convenient to move in the workshop.

l Touch screen: easily to modify and save the parameters.

l Integrated dust extraction port on cleaning head: No extra dust extraction pipe needed.

l Integrated chiller & dust extraction system inside.

l Adopted spiral cleaning method: to avoid damage on the surface of parts

l Top hat beam mode: with high efficiency and no damage on the substrate surface. a good choice on cleaning mould, paint, floating rust, saponification liquid and oil stain.

l High tolerance technology: focus height tolerance can be up to 40 mm range, it is beneficial to improve the cleaning efficiency under the condition of uneven surface and reduce the focusing requirements of hand-held operation.

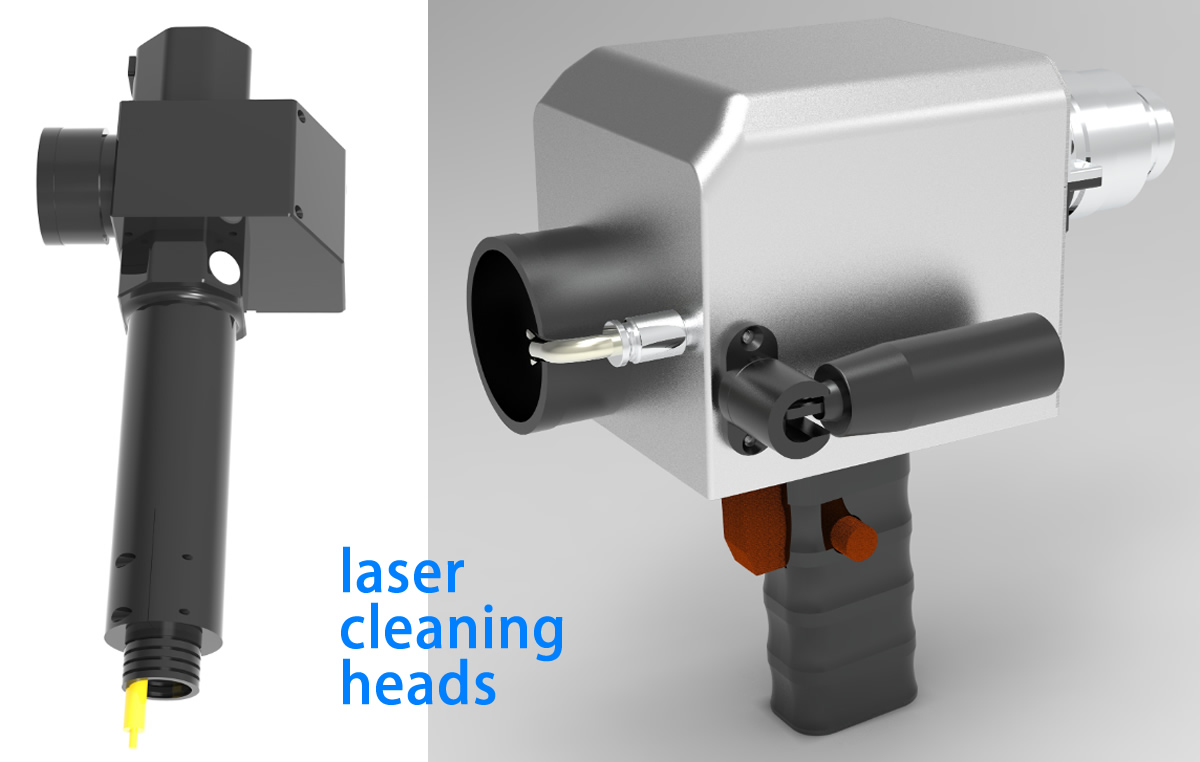

Laser cleaning machine consists of two parts: cart cleaning control system and laser cleaning head.

Cart Cleaning Control System

It’s easy to manually move to the work area to achieve target selection and positioning cleaning. The product has high average power (200W), high single pulse energy (10mJ), high average power (200W), high single pulse energy (10mJ), top hat mode, high beam uniformity; uniform distribution of spot energy, good bottom processing effect, no damage to substrate, high cleaning efficiency, easy to use and maintenance.

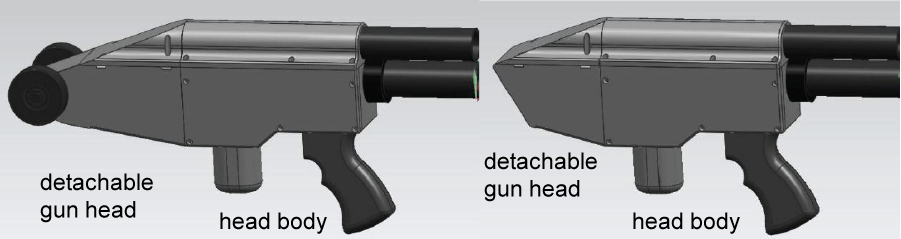

Laser Cleaning Head

It is equipped with a long exhaust nozzle and a short exhaust nozzle. The long exhaust nozzle is equipped with a roller, which can directly roll on the surface of the workpiece and it is convenient for manual hand-held cleaning operation to fix the focus. The short exhaust nozzle without roller can set the cleaning length up to 110mm. The hand-held cleaning gun can realize the spiral cleaning mode, which has obvious advantages over the ordinary linear cleaning method. The linear cleaning method will form color difference marks (called zebra stripes) on the surface of the parts due to the unstable hand speed of the operator. The spiral cleaning method makes the laser focus run in spiral lines, and does not form color difference marks on the surface of the parts.

Model | STF-FED-CLD200R | STF-FED-CLD300R |

Average laser power | 200W | 300W |

Single pulse energy | 10mJ | 12.5mJ |

Repeat frequency | 20-50kHz | 20-50kz |

Beam mode | Top hat | Top hat |

Wavelength | 1064±5nm | 1064±5nm |

Focus length | 160mm | 160mm |

Scan length | 1-100mm | 1-100mm |

Scan width(in spiral mode) | 1-10mm | 1-10mm |

Cooling method | Water | Water |

Max consumption | 2500W | 3300W |

Environment temperature | 0~40℃ | 0~40℃ |

Weight | 200kg | 220kg |

Size | 1060x620x1020mm | 1060x620x1020mm |

Cleaning paint / rust (20um) | 9.5㎡/h | 13㎡/h |

Cleaning oil pollution (20um) | 11㎡/h | 15㎡/h |

Cleaning oxide film of titanium alloy | 7㎡/h | 9.5㎡/h |

Model | STF-FED-LCD200I |

Fiber Laser | IPG |

Laser power | 200W |

Beam Mode | Top hat |

Power adjustment range | 10~100(%) |

Stability of laser power | <5% |

Beam Quality(M2) | 9~10 |

Wavelength | 1064±5 |

Polarization | random |

Repeat frequency adjustment range | 10~50kHz |

Output fiber length | 3m (other lengths available) |

Environment temperature | 10~40℃ |

Cooling method | Water |

Power supply | 220VAV, 50/60Hz, 2.5kW |

Scan length | 5-110mm |

Scan depth of focus | ±20mm |

Scan width (in spiral mode) | 2-10mm |

Cleaning oxide film of titanium alloy | 7㎡/h |

Cleaning paint / rust (20um) | 9.5㎡/h |

Cleaning oil pollution (20um) | 11㎡/h |

Dust extractor & filter

Model | STF-LB-JZ150 | STF-LB-JZ1500 |

Power | 150W | 1500W |

Working noise | 60dB | |

air volume flow | 320m3/h | 1500m3/h |

Purification rate (0.5um) | 99.7% | 99.9% |

Power Supply | 220VAC | 380VAC |

Remark:

STF-LB-JZ150 is a built-in extractor, which is placed in the cleaning machine control system.

STF-LB-JZ1500 is an external extractor. It is better to add the external extractor when the cleaning head is over 10 meters away from the control system.

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 18 South Liu Fang Yuan Road, Sintec Industrial Park, Optics Valley of China, Wuhan Hubei, 430205 PR China

Mobile/Wechat: +86 19913132317

Whatsapp: +86 19913132317

E-mail: sales@SintecOptronics.cn