SHC Series Servo Motors and DriversWe are a leading global provider of industrial automation solutions to OEMs and end users with servo motors & drivers, PLCs and motion controllers. The company’s flexible production techniques and expert understanding of all industry sectors – from plas

We are a leading global provider of industrial automation solutions to OEMs and end users with servo motors & drivers, PLCs and motion controllers. The company’s flexible production techniques and expert understanding of all industry sectors – from plastics to printing to packaging to iron & steel production – have allowed it to establish globally leading industry-specific business units. Over the years, we have built an engineering team with specialist expertise in industrial automation. Their combined knowledge makes the company one of the world’s foremost industrial automation partners, and enables it to form long-term relationships with customers. This means that we can provide ongoing advice about how to get the most out of their automation solutions today, and how to stay prepared for the market and technology changes that are coming in future.

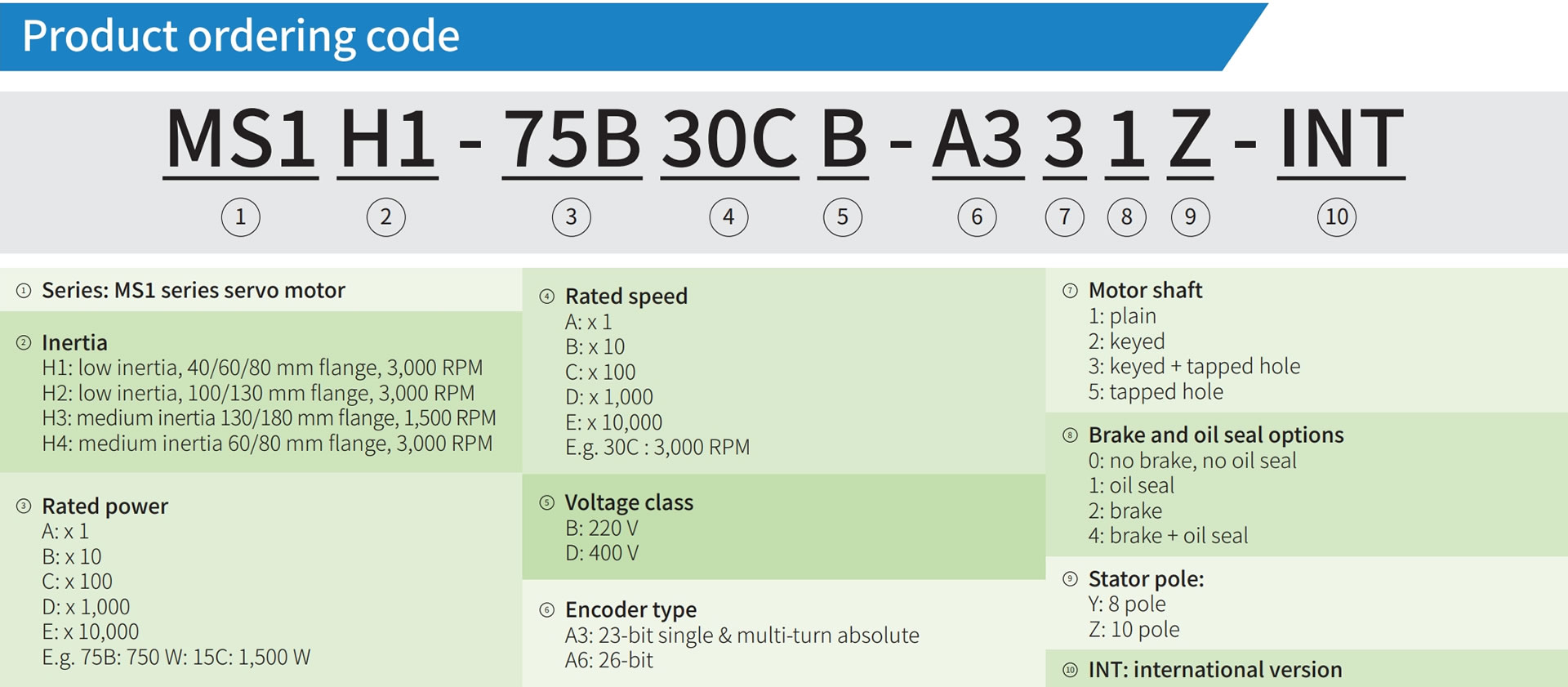

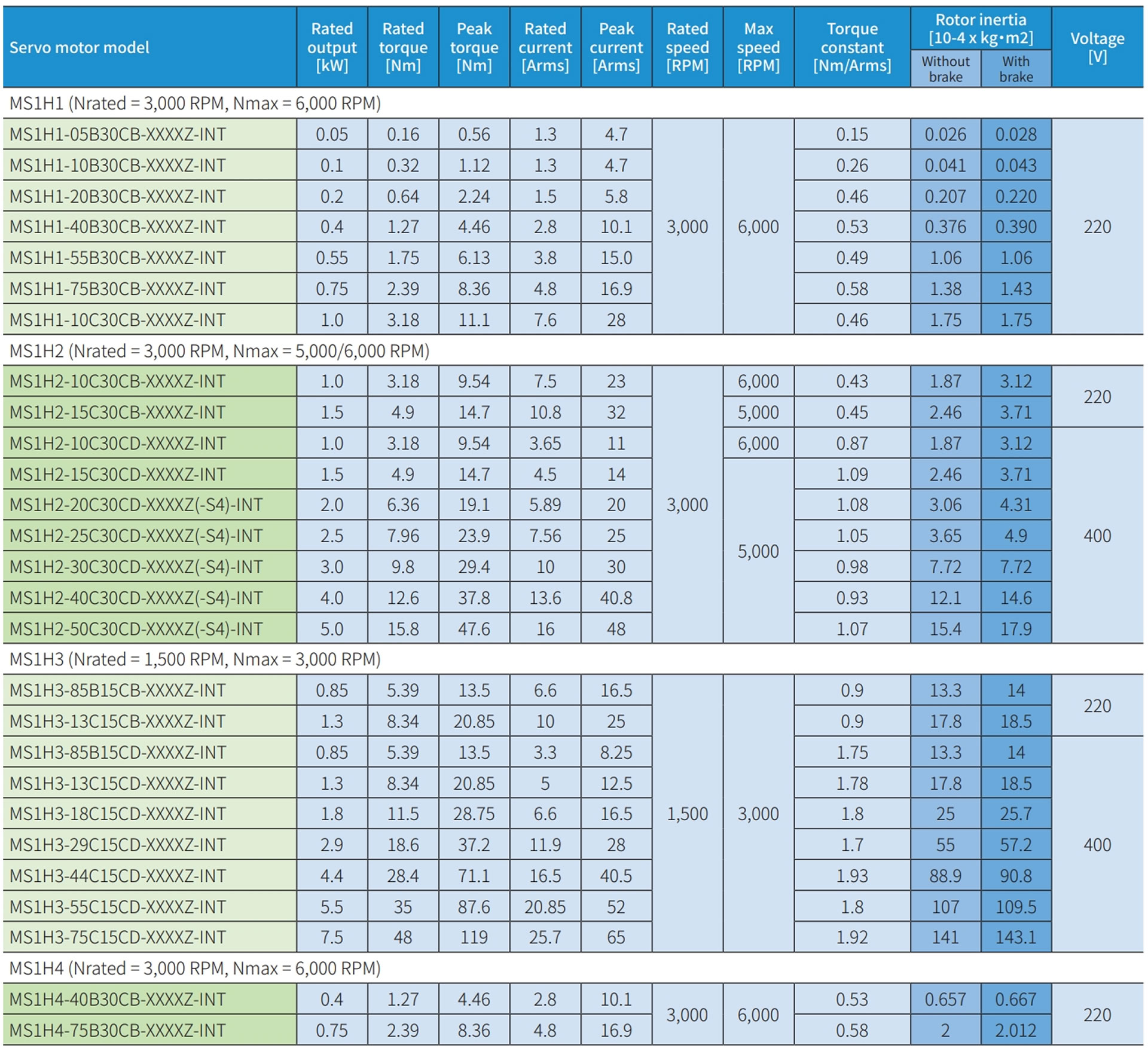

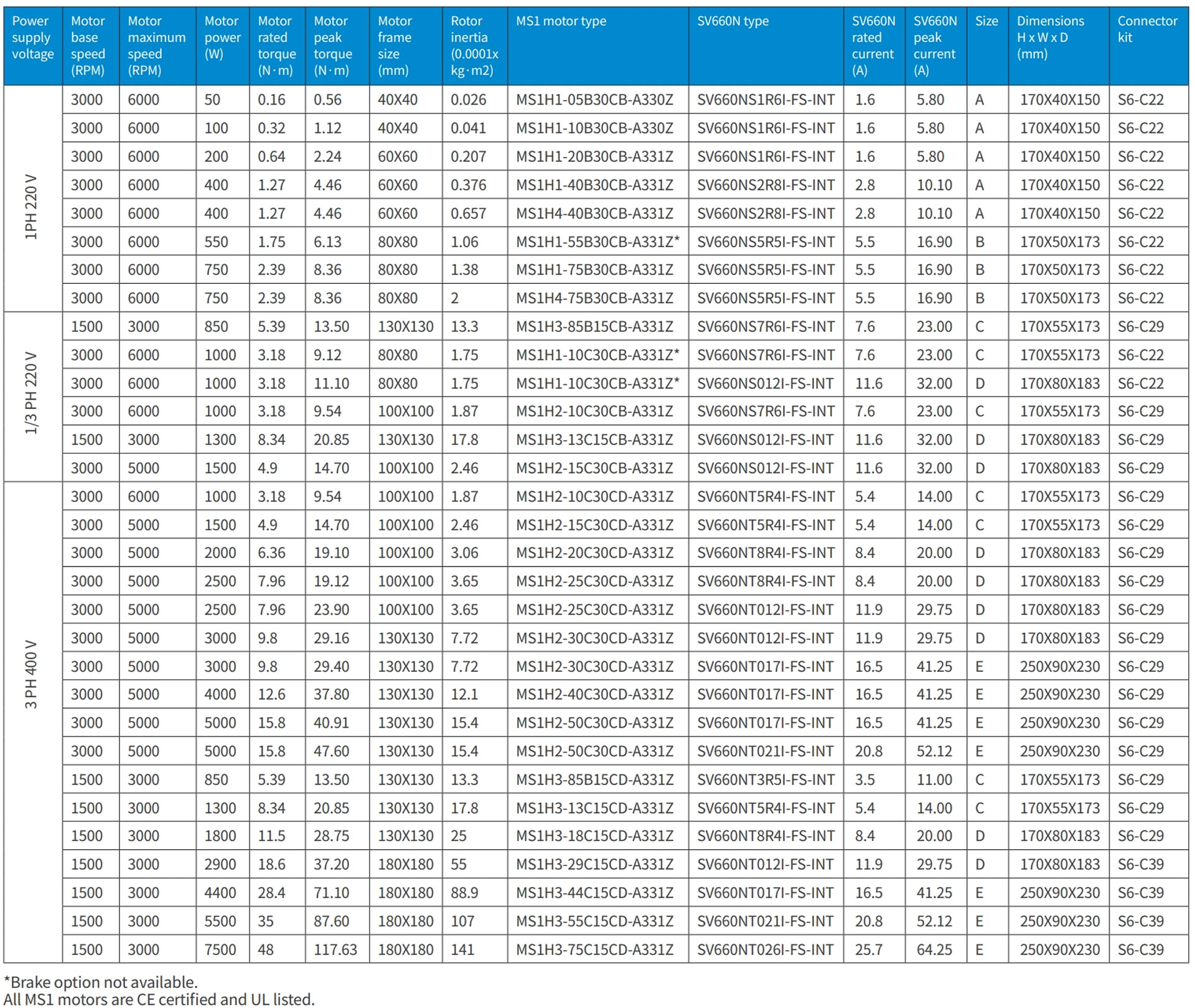

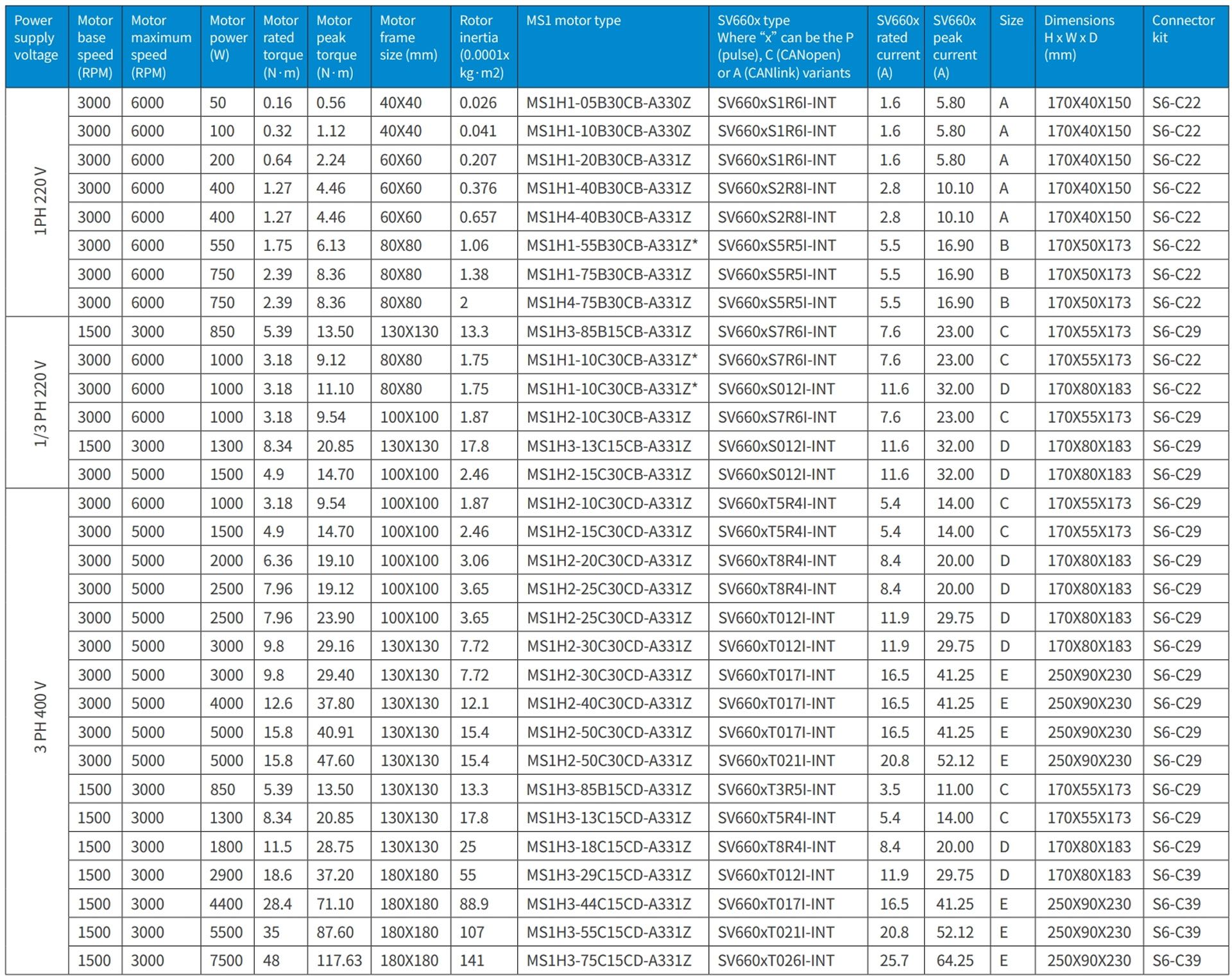

1.1 MS1 series servo motors

The highly dynamic MS1 servo motor range has a wide variety of power ratings, as well as flange and brake options. The motor family benefits from a small footprint that reduces overall machine size.

MS1H1/H4 series

From 0.16 to 3.2 Nm

Easy motor and encoder connections

23 bit motor encoder feedback: +/-15 arcseconds

Up to 350% maximum peak torque

Torque fluctuation <0.5%

IP67 rating

Complies with CE and UL

MS1H2/H3 series

From 3.2 to 47 Nm

23 bit motor encoder feedback: +/-15 arcseconds

Up to 300% maximum peak torque

Torque fluctuation <1%

IP67 rating

Complies with CE and UL

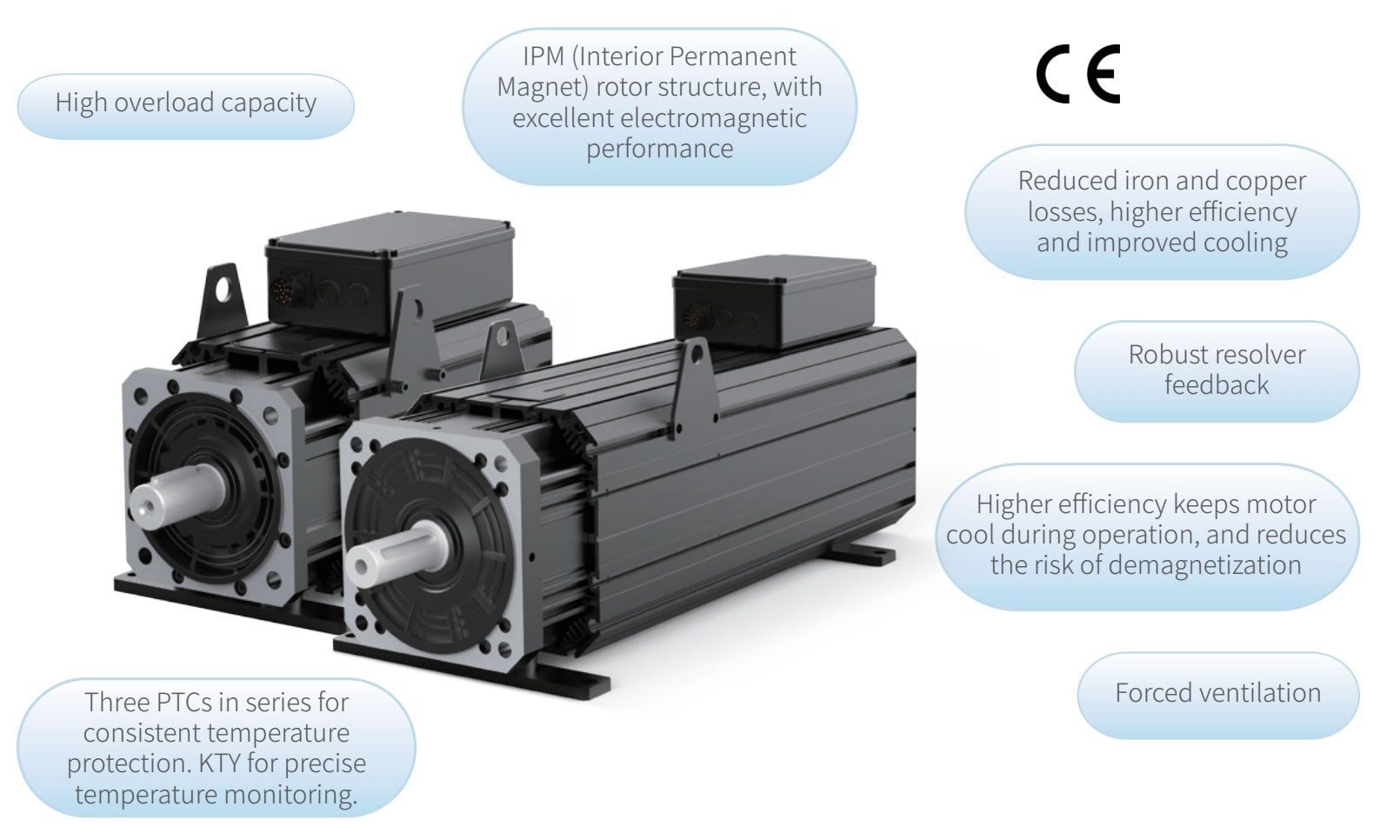

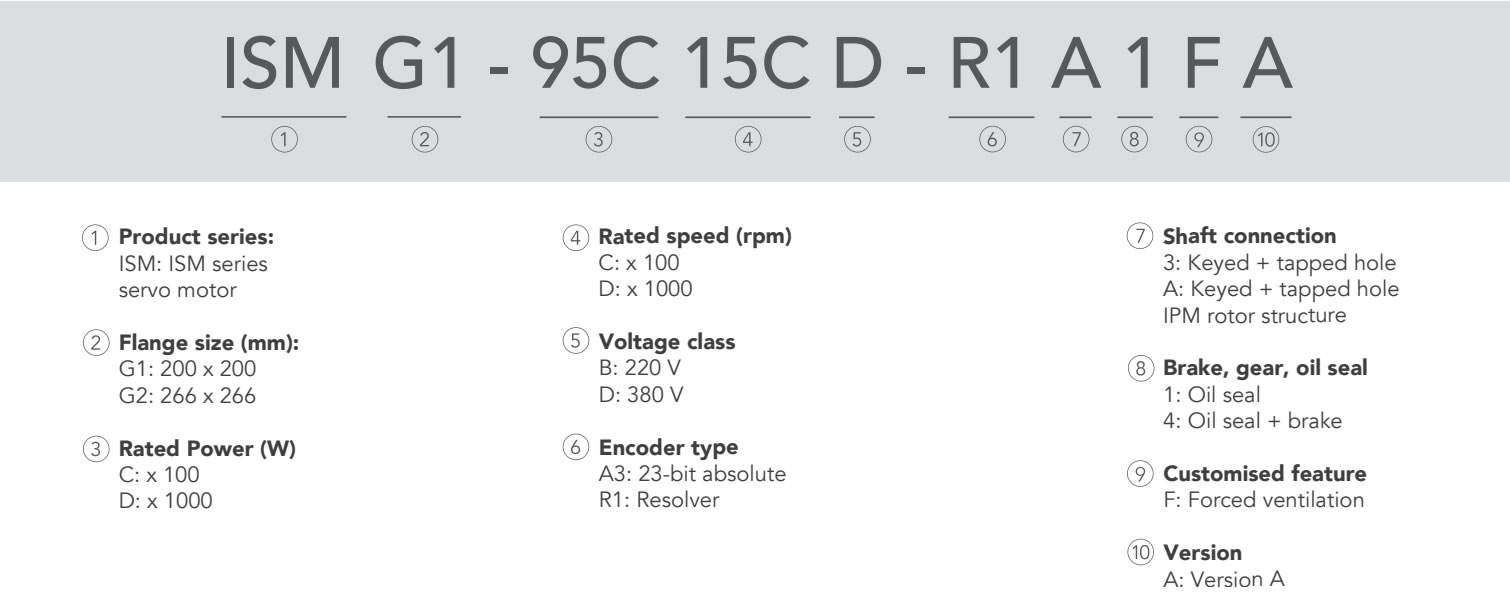

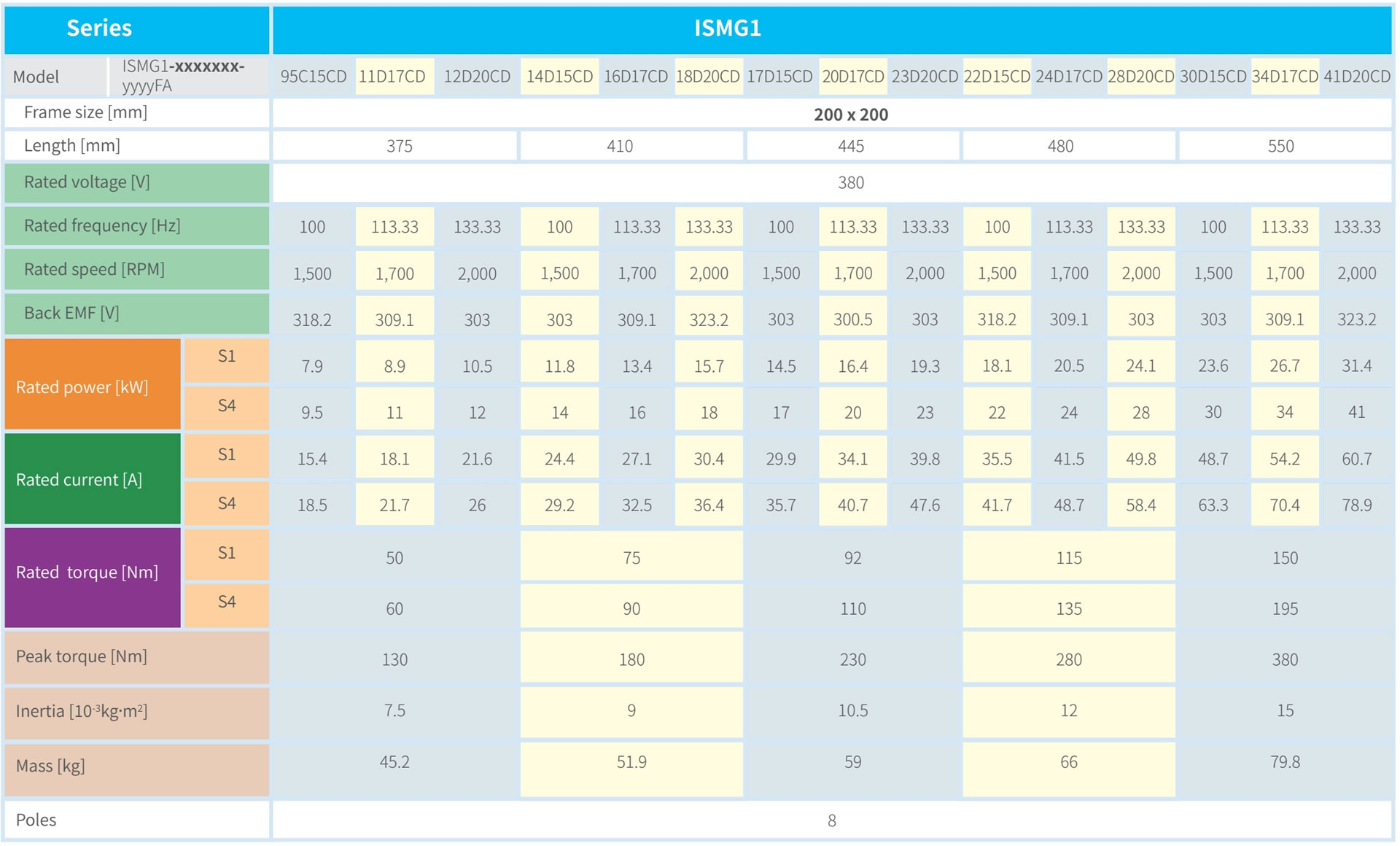

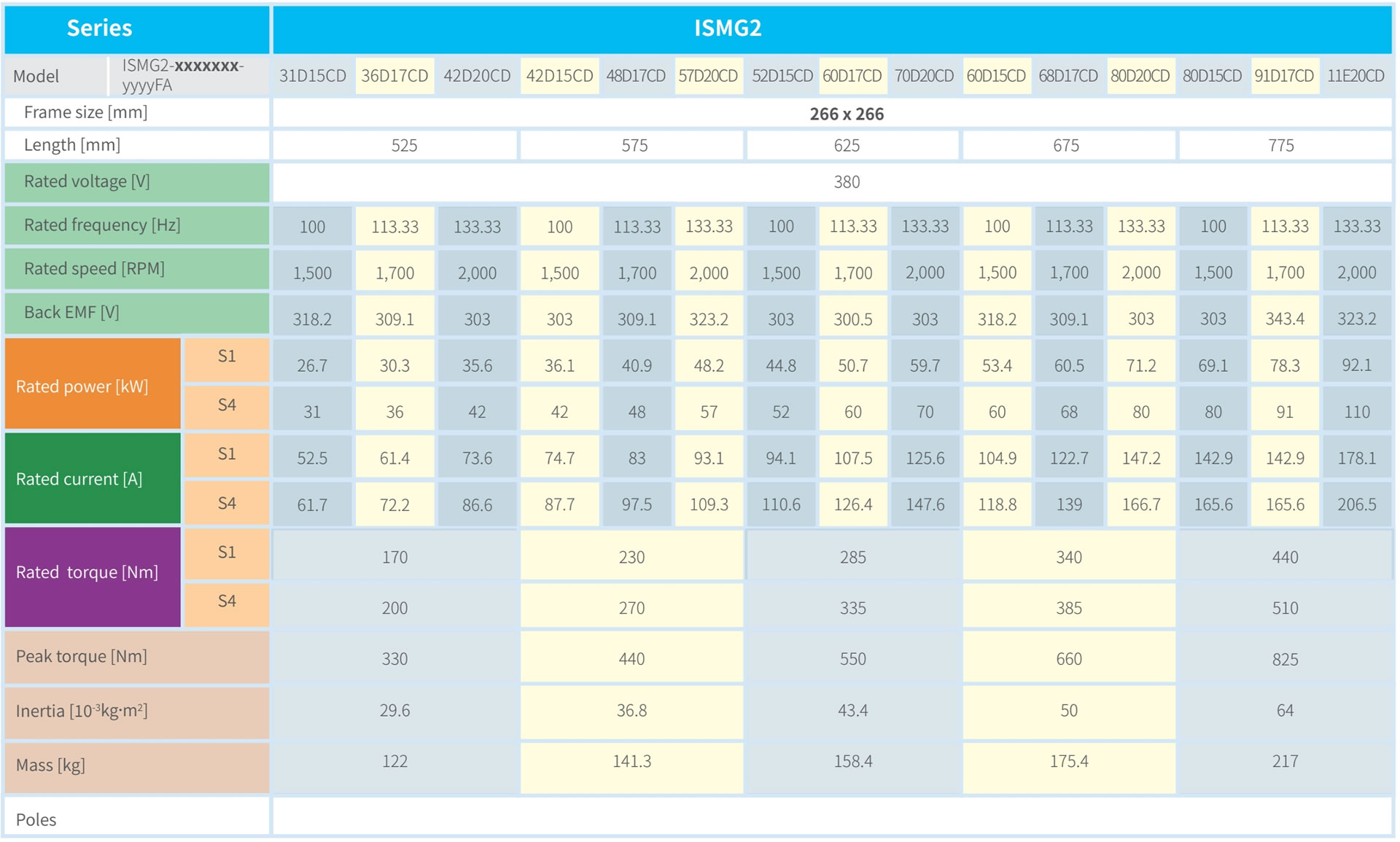

1.2 ISMG series servo motors

Servo motor designed for energy saving servo pump applications

High overload capacity

Excellent electromagnetic performance with interior permanent magnet rotor structure

Higher efficiency and improved cooling with reduced iron and copper losses

Robust resolver feedback

Higher efficiency keeps motor cool during operation, and reduces the risk of demagnetization

Forced ventilation

Consistent temperature protection with three PTCs in series

Precise temperature monitoring with KTY

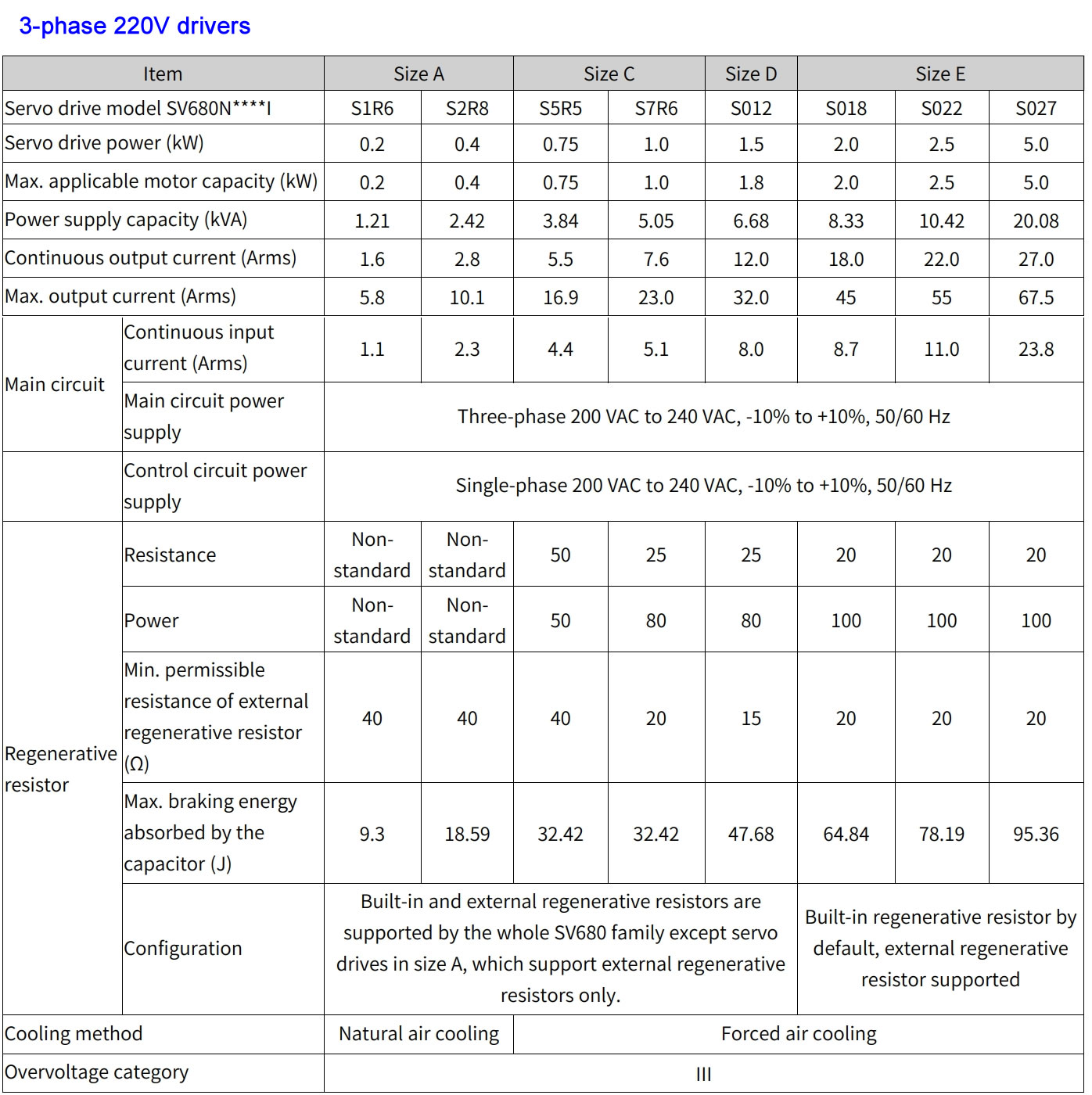

2.1 SV660N servo drivers

High dynamic performance with a compact footprint: the SV660N servo solution for industrial automation applications

User friendly installation

Easy set-up and tuning

Ultra-fast 4.5kHz current loop

Speed loop bandwidth up to 3kHz

Supply voltage: Single phase 220V; Three phase 220V; Three phase 380V

0.1-7.5kW

Safe Torque Off - SIL3

Complies with CE and UL

2.2 SV660P - Single-Axis Pulse Servo Driver

Performance and flexibility in a compact footprint.

User friendly installation

Easy set-up and tuning

CANopen (C) and CANlink (A) variants also available

Speed loop bandwidth up to 2kHz

Supply voltage: Single phase 220V; Three phase 220V; Three phase 380V

0.1-7.5 kW

Complies with CE and U

Product variants:

(1) SV660P - pulse control variant

Pulse interface for position control (4MHz maximum input frequency).

(2) SV660C - CANopen variant

Compliant with CiA 402 device profile (IEC 61800-7-201/301), supporting several operation modes.

(3) SV660A - CANlink variant

Uses our proprietary protocol, in combination with our controller products

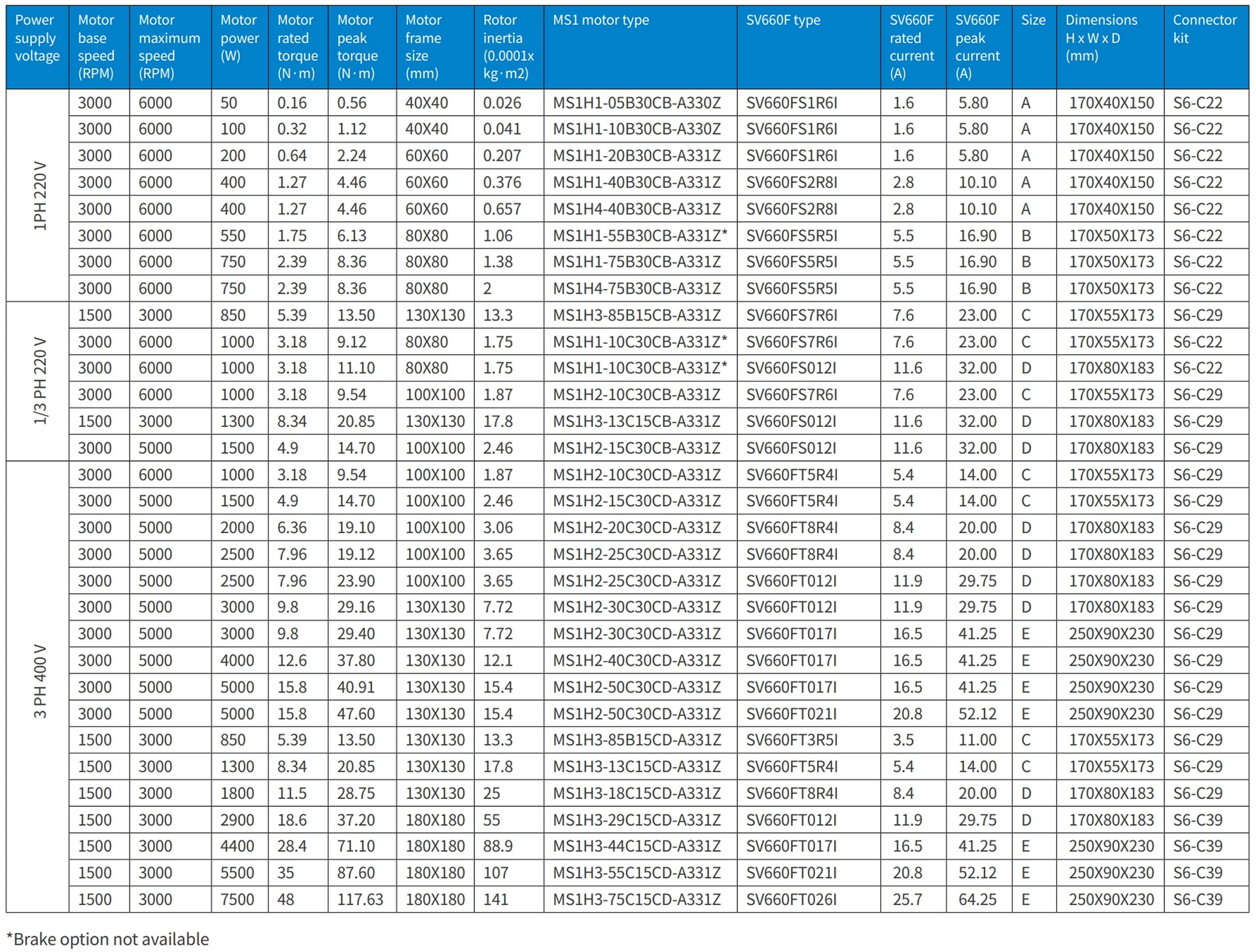

2.3 SV660F – Single-Axis PROFINET Servo Driver

High dynamic performance with a compact footprint:

the SV660F servo solution for industrial automation applications.

User friendly installation

Easy set-up and tuning

Ultra-fast 4.5kHz current loop

Safe Torque Off - SIL3

PROFINET RT and IRT communication

Supports PROFIdrive device profile

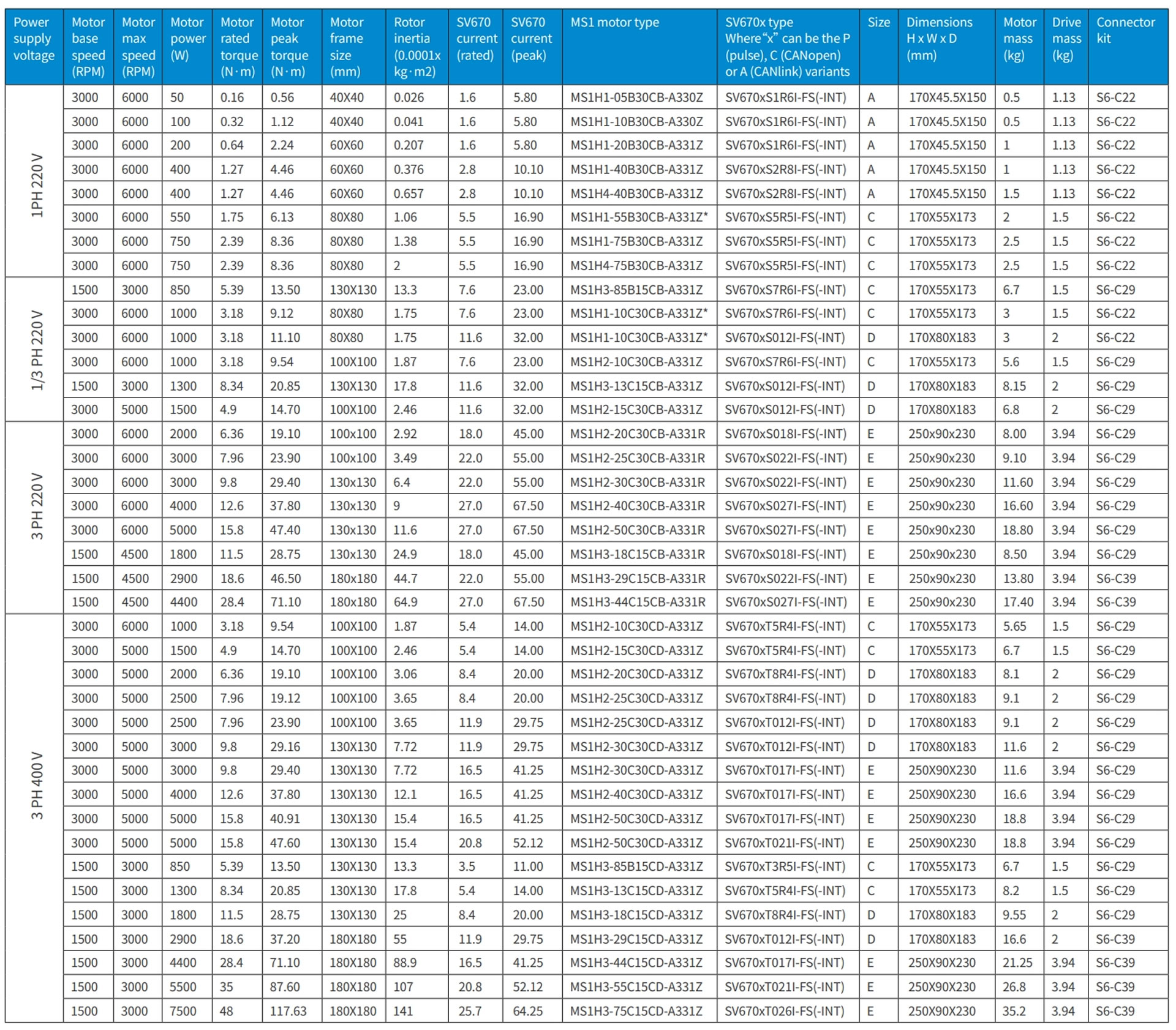

2.4 SV670P – Single-Axis Pulse Servo Driver

User friendly installation

Easy set-up and tuning

CANopen (C) and CANlink (A) variants also available

Safe Torque Off - SIL 3

1/3 ph 200V, 3 ph 400V, kW to 7.5kW

Ultra-fast 4.5kHz current loop

Feedback encoder interface: serial (Weton), Nikon and Tamagawa

Second encoder interface: incremental quadrature

+24VDC backup control supply variant available

Product variants:

(1) SV670P - pulse control variant

Pulse interface for position control (4MHz maximum input frequency).

(2) SV670C - CANopen variant

Compliant with CiA 402 device profile (IEC 61800-7-201/301), supporting several operation modes.

(3) SV670A - CANlink variant

Uses our proprietary protocol, in combination with our controller products

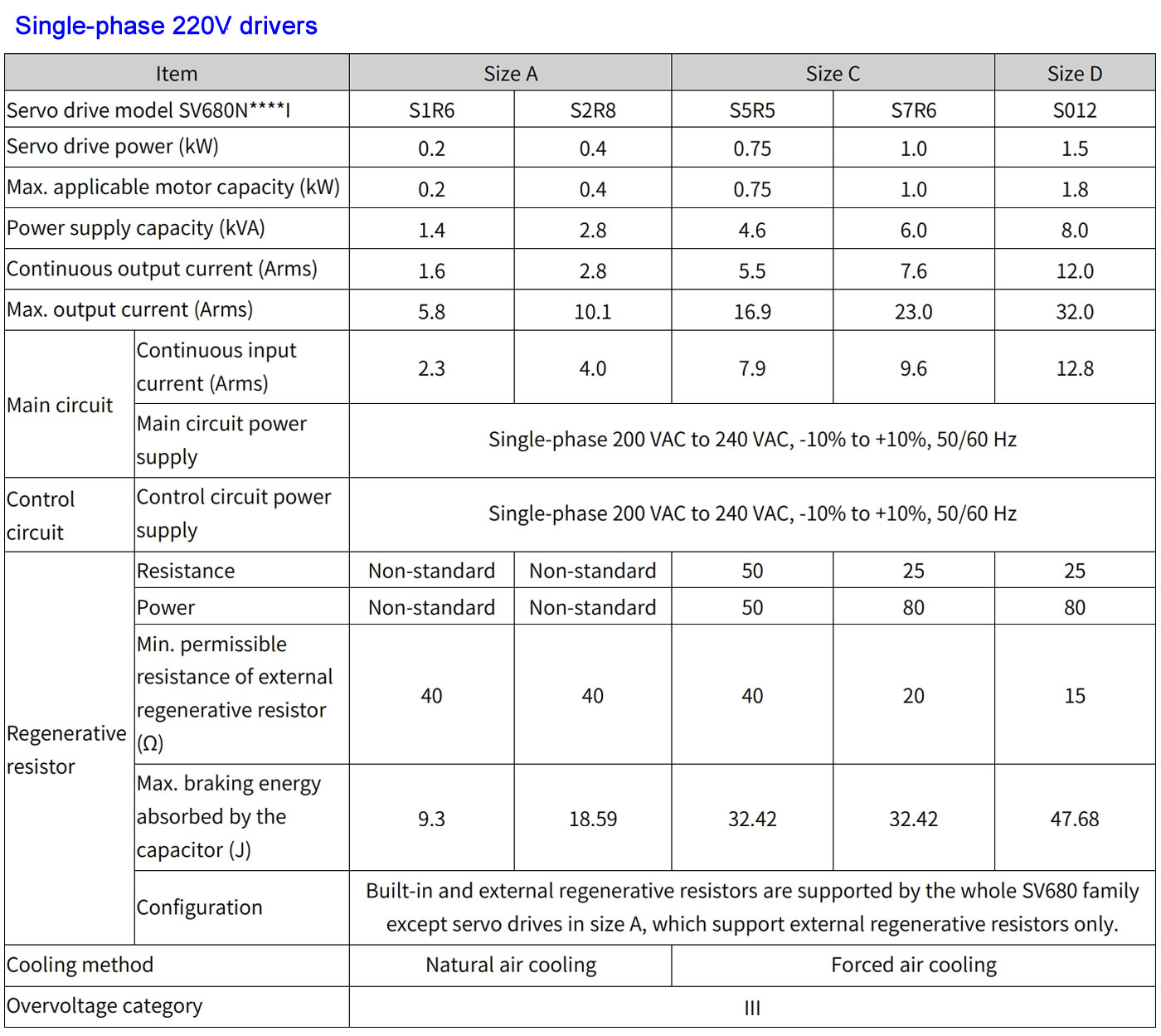

2.5 SV680N servo driver

The SV680N series servo driver is a high-end servo drive designed based on global[1]leading standards and high-end application needs. It is featured with high speed, high precision, high performance, and tuning-free function. Covering a power range from 0.05kW to 7.5kW, the SV680N series servo driver carries EtherCAT communication interfaces to work with the host controller for a networked operation of multiple servo drivers. It is equipped with the latest ITune function that allows adaptive stiffness level setting, inertia auto-tuning, and vibration suppression for easy control. The SV680N series servo driver, together with an MS1 series high[1]response servo motor (with ultra-low, low or medium inertia) equipped with a 26-bit single-turn/multi-turn absolute encoder, aims to deliver a quiet and stable operation and accurate process control through the fully closed-loop function and internal process segment function.

SV680N | |

Control mode | Cyclic synchronous position mode |

Cyclic synchronous velocity mode | |

Cyclic synchronous torque mode | |

Profile position mode | |

Profile velocity mode | |

Profile torque mode | |

Homing mode | |

Fully closed‑loop control | |

Terminal | STO |

CN1 16‑pin I/O terminal | |

DB44 | |

DB15 | |

Communication protocol | EtherCAT |

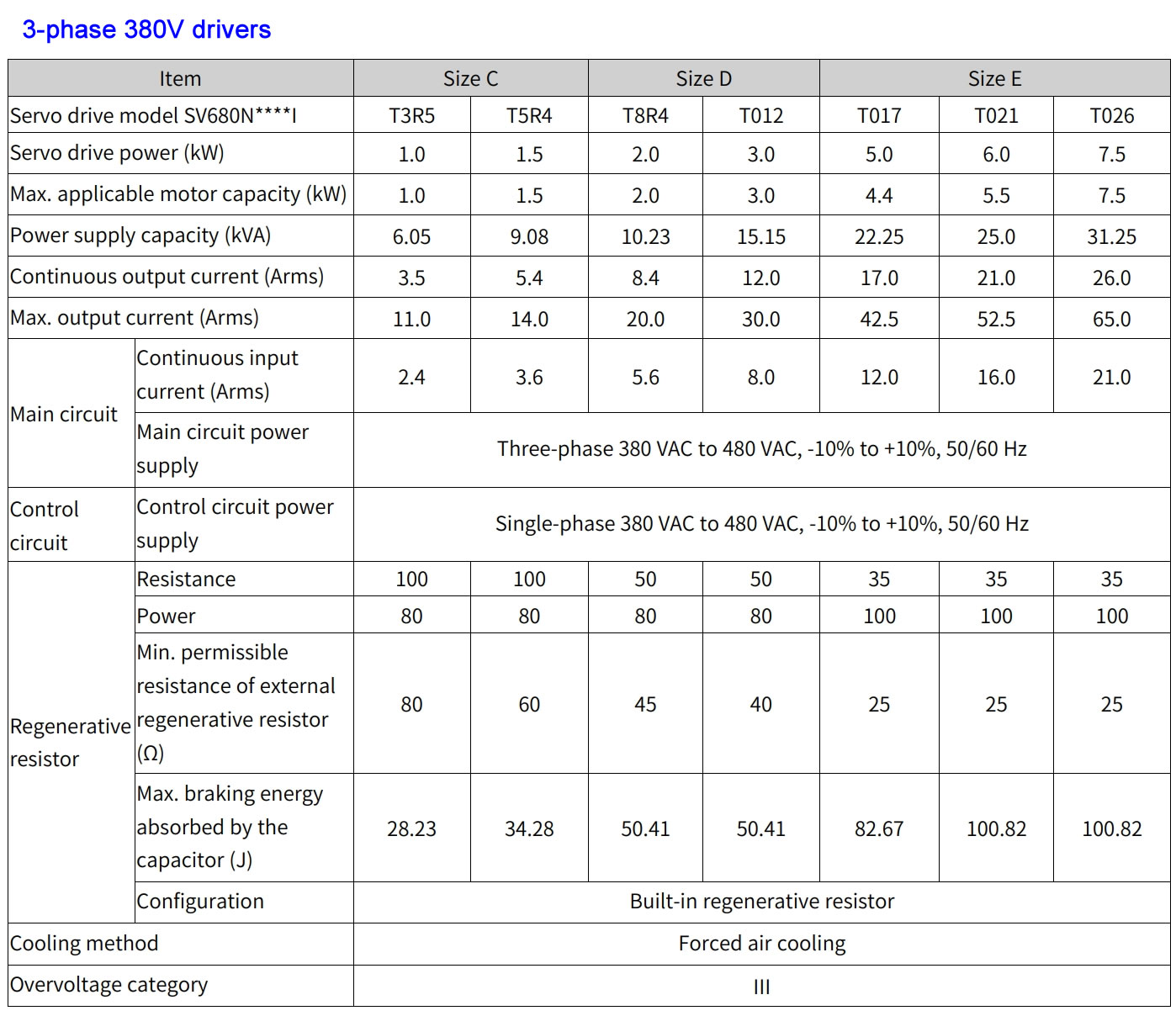

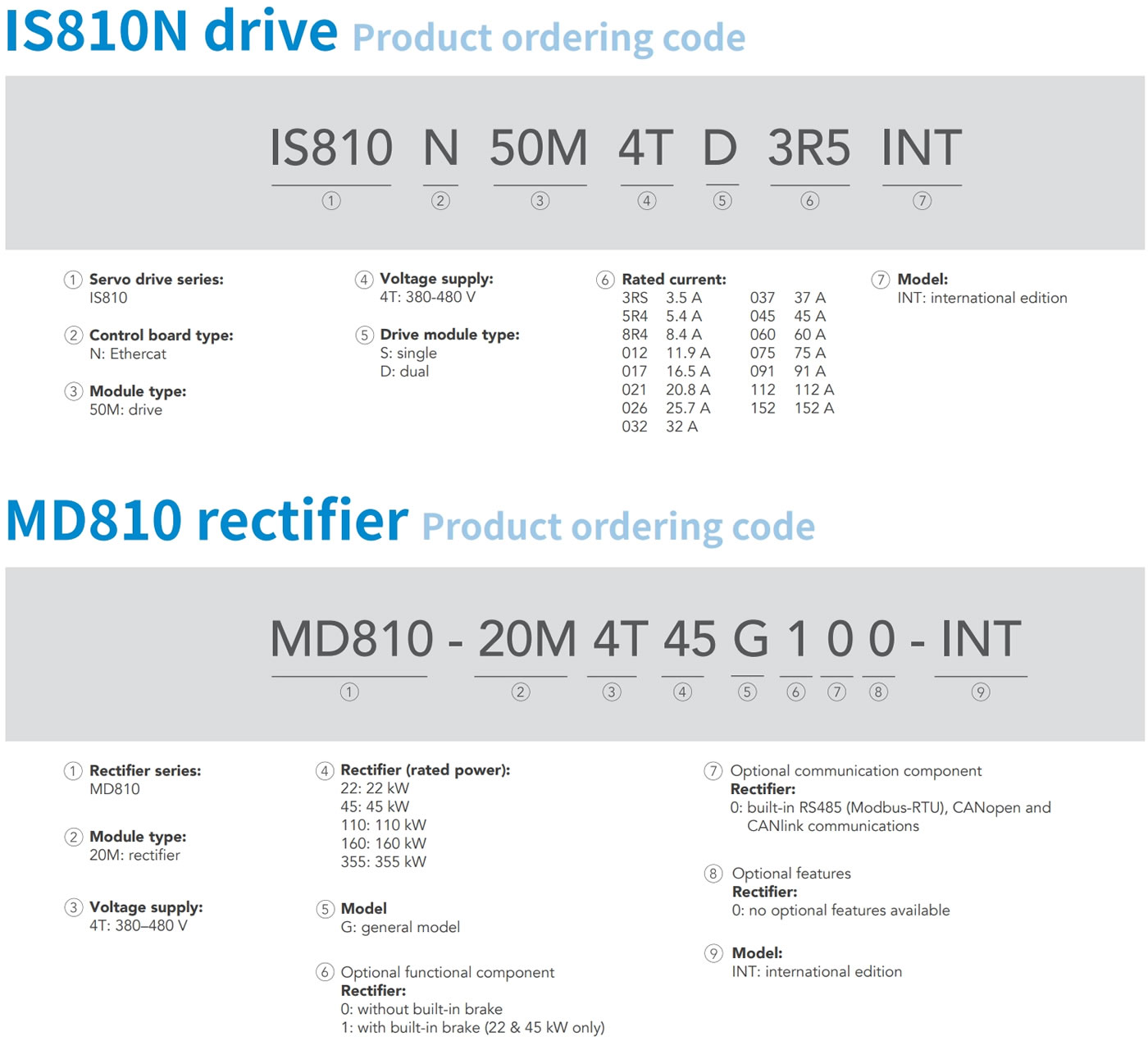

2.6 IS810N servo drivers

Multi-axes servo drive platform – for maximum performance in the most demanding applications

Common power supply module: 22-355kW

Single and dual axes modules: 850 W -75kW*

Three phase 400V supply voltage

Ultra-fast 4.5kHz current loop

Speed loop bandwidth up to 2kHz

Safe Torque Off – SIL 3

Complies with CE

* dual axes available up to 18.5kW

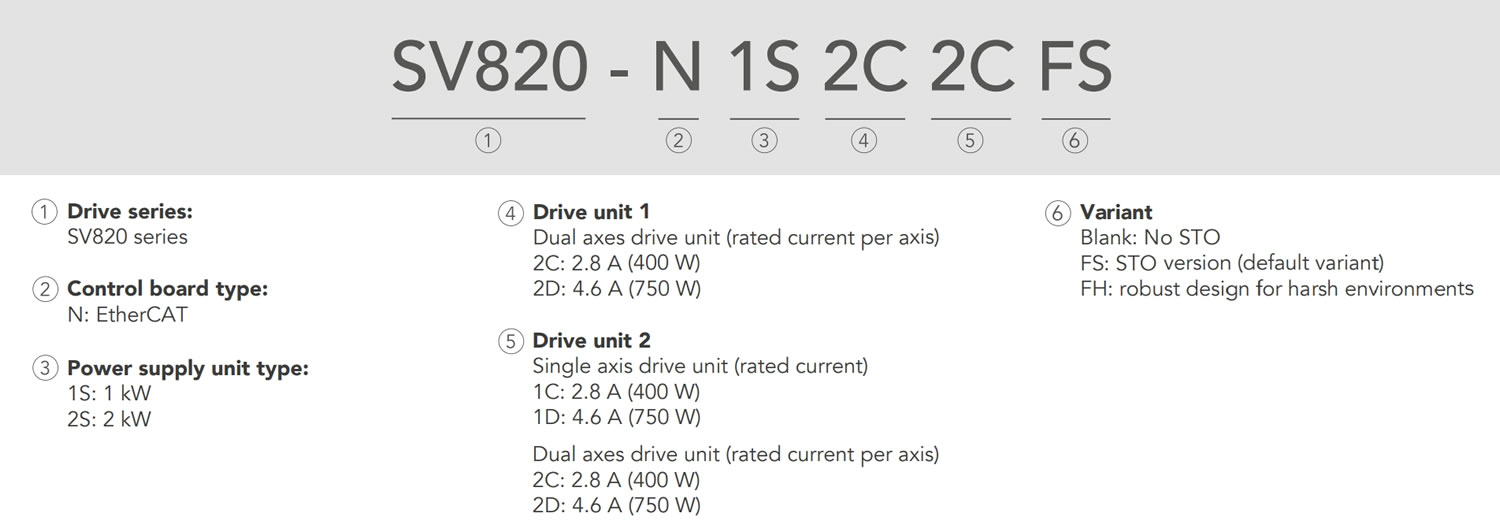

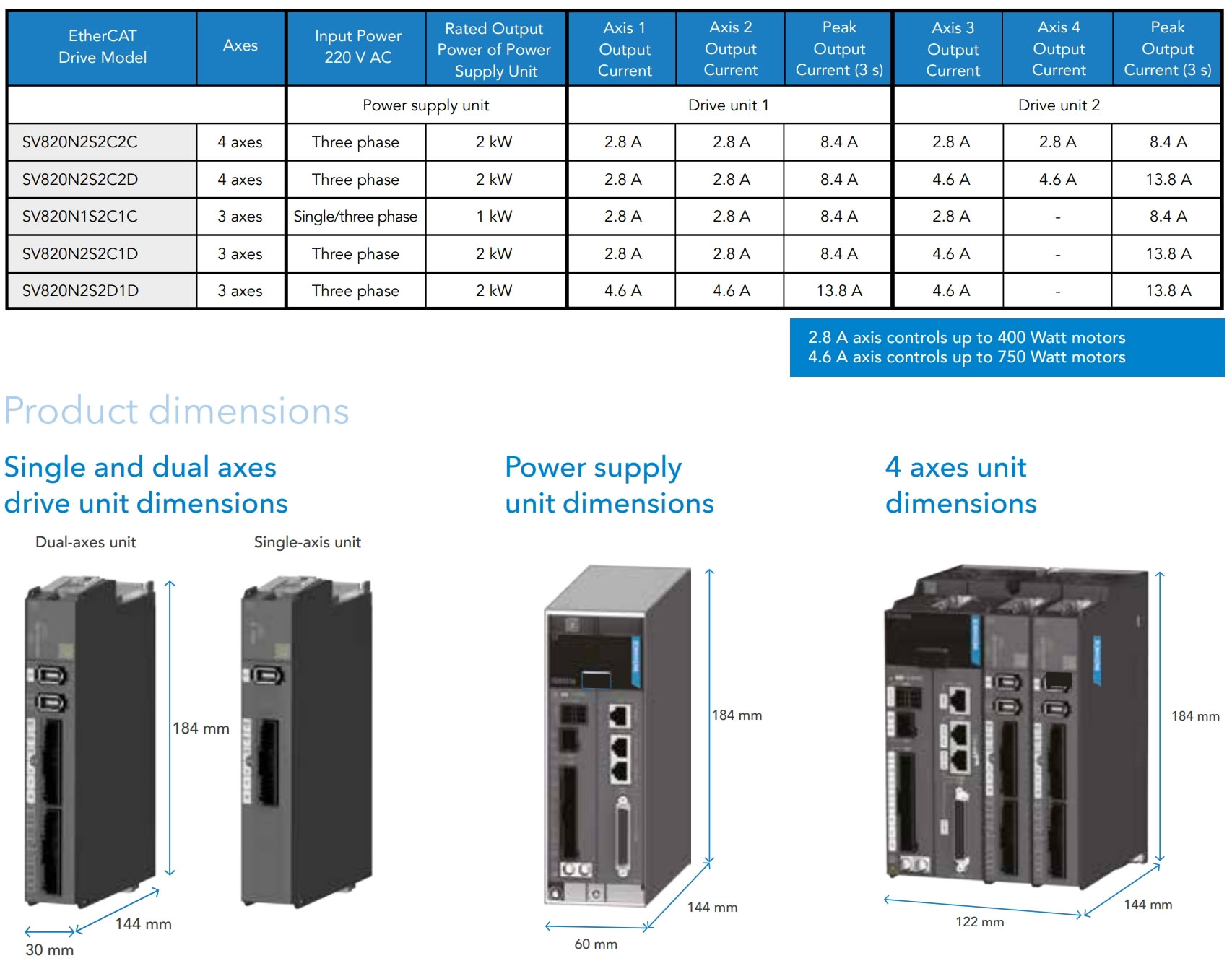

2.7 SV820N multi-axes servo drivers

A multi-axes servo platform, available in 3 or 4 axes versions, with a common power supply module. The drive features an ultra-fast control loop regulator and a high dynamic response rate. It is designed to seamlessly integrate with MS1 motors from 50-750W. Supports CANopen and EtherCAT communications

Power supply unit: 1-2kW

Single/double unit axis module: 1.1-7.6A

Ultra-fast current loop

STO SIL 3 – in accordance with EN/IEC 61800-5-2

EtherCAT CiA 402 motion profile as standard

Easy commissioning and installation

Small footprint for robot applications

IP67

Complies with CE

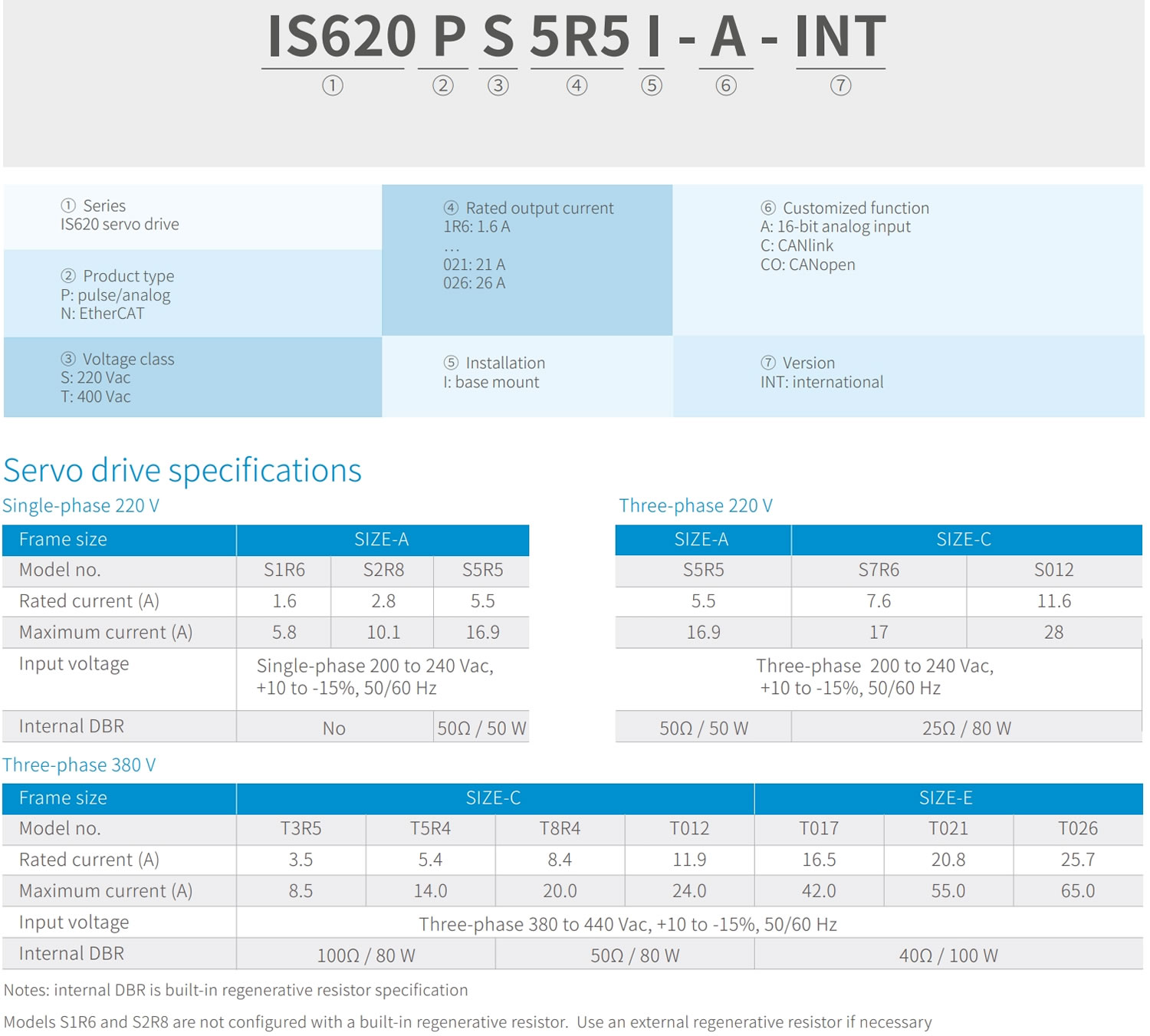

2.8 IS620 servo drivers

2.8.1 IS620N servo driver

Ethercat servo driver for industrial applications

Speed loop bandwidth up to 1.2kHz

Supply voltage: Single phase 220V; Three phase 220V; Three phase 380V

0.1-7.5kW

EtherCAT communications

Built-in keypad

Fine tuning with PC software (InoServoShop)

Inertia auto-tuning (on-line/off-line)

Automatic gain tuning

Adaptive notch filter

Automatic/manual damping filter for low frequency resonance

Complies with CE

2.8.2 IS620P servo driver

High performance servo system

High speed loop bandwidth: up to 1.2kHz

Supply voltage: Single phase 220V; Three phase 220V; Three phase 380V

0.1-7.5 kW

Pulse/direction

CANopen communications (IS620P-CO variant)

Built-in keypad

Fine tuning with PC software (InoServoShop)

Inertia auto-tuning (on-line/off-line)

Automatic gain tuning

Adaptive notch filter

Automatic/manual damping filter for low frequency resonance

Complies with CE

A complete product range – from the simplest to the most complex motion control capable PLC. Our PLCs are reliable and durable. They are available in small and medium sizes, support bus applications, and can be flexibly combined. Meanwhile, our HMIs offer clear displays and an easy-to-use format. They can be integrated with any third party equipment, but, for optimal performance, are designed to be used as a package with other products, such as PLCs and variable speed drives.

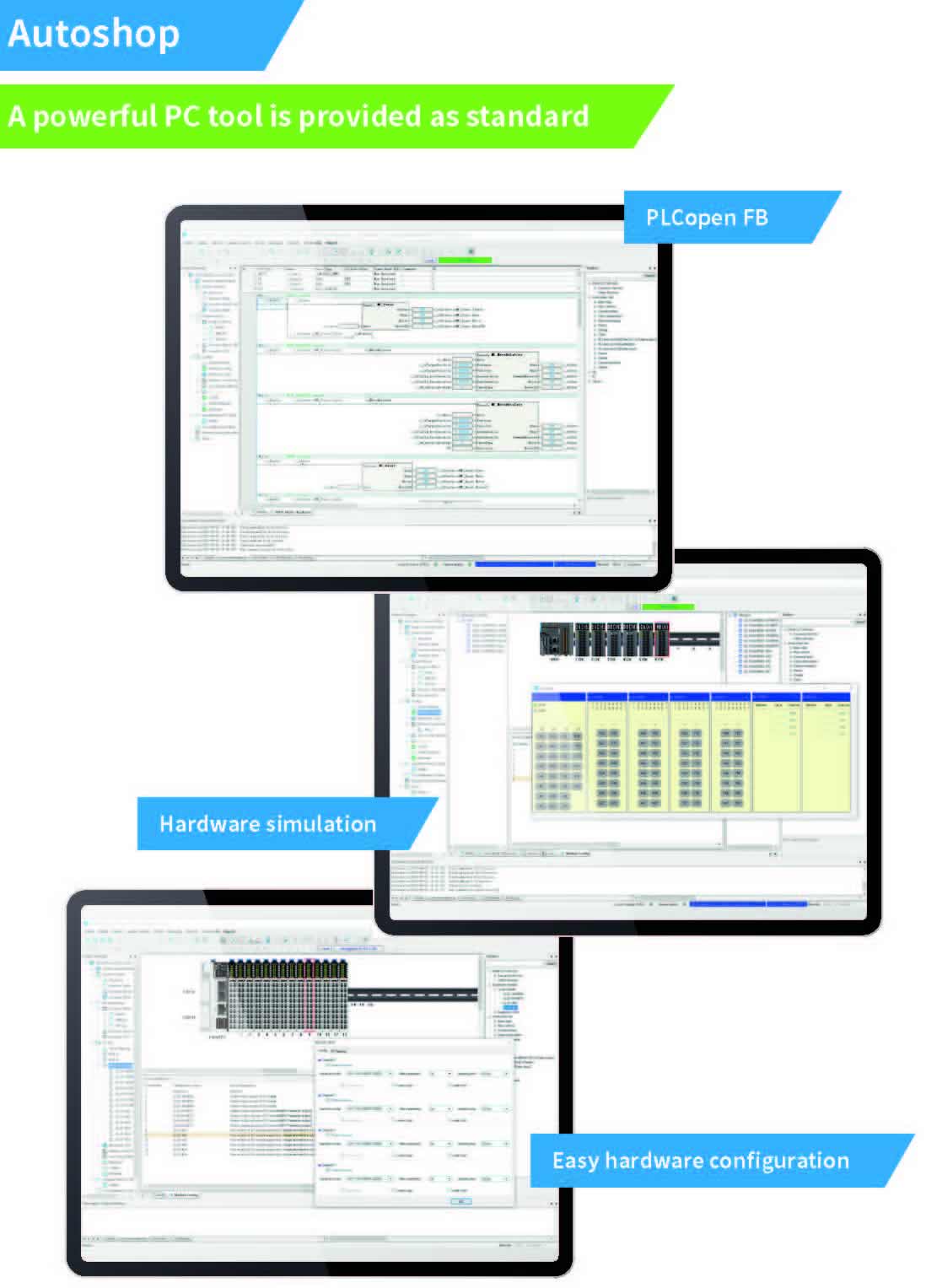

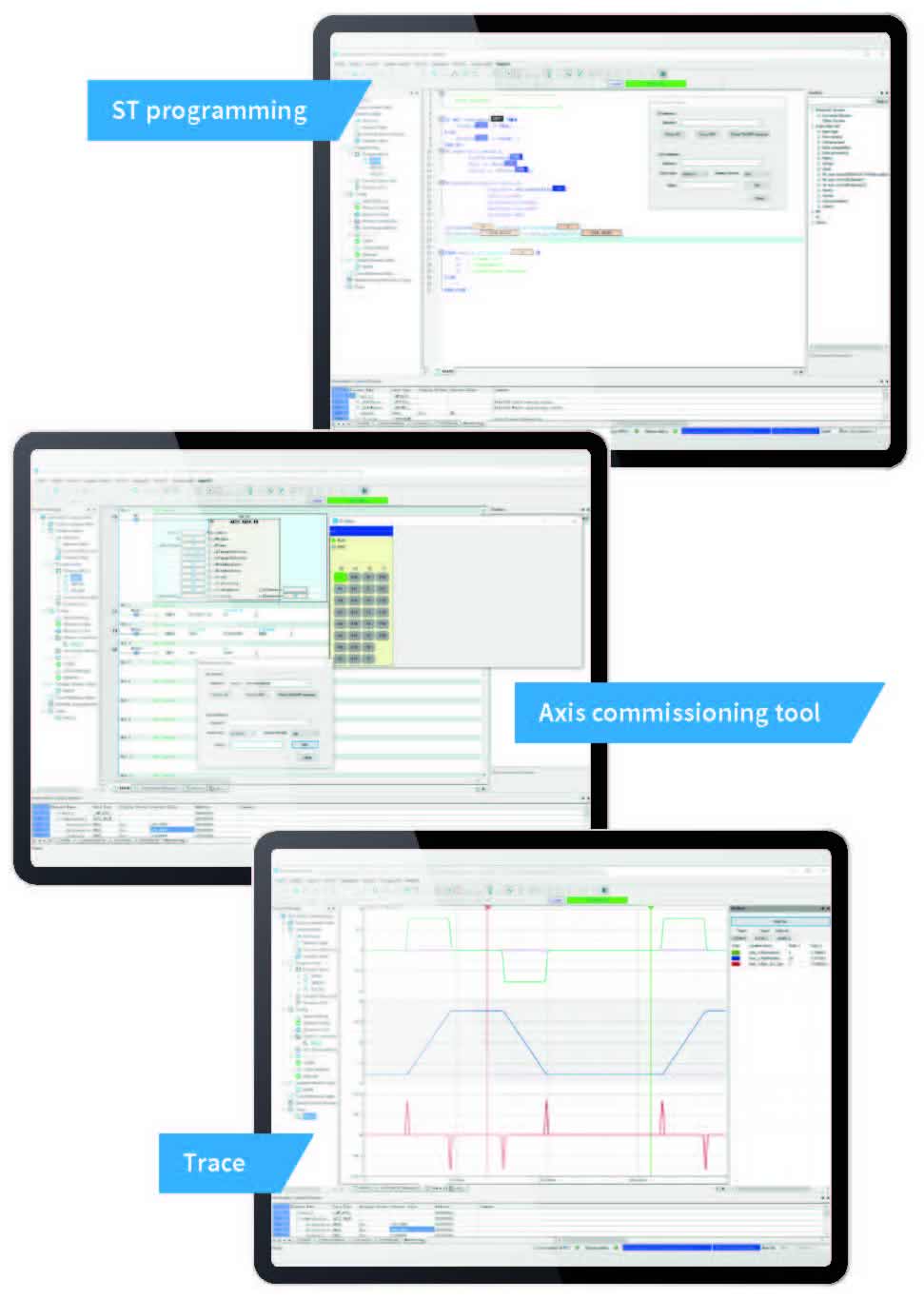

PLCopen compliant axis control

Simulation mode for offline debugging

Real-time fieldbus

Axis group for lineal and circular interpolation, CAM table functionality

Supports function block and function for encapsulation, code reusability, and scalability

ST, LD, SFC language support

Multiple communication protocols: Modbus RTU/TCP; CANopen (optional); Ethernet/IP (scanner)

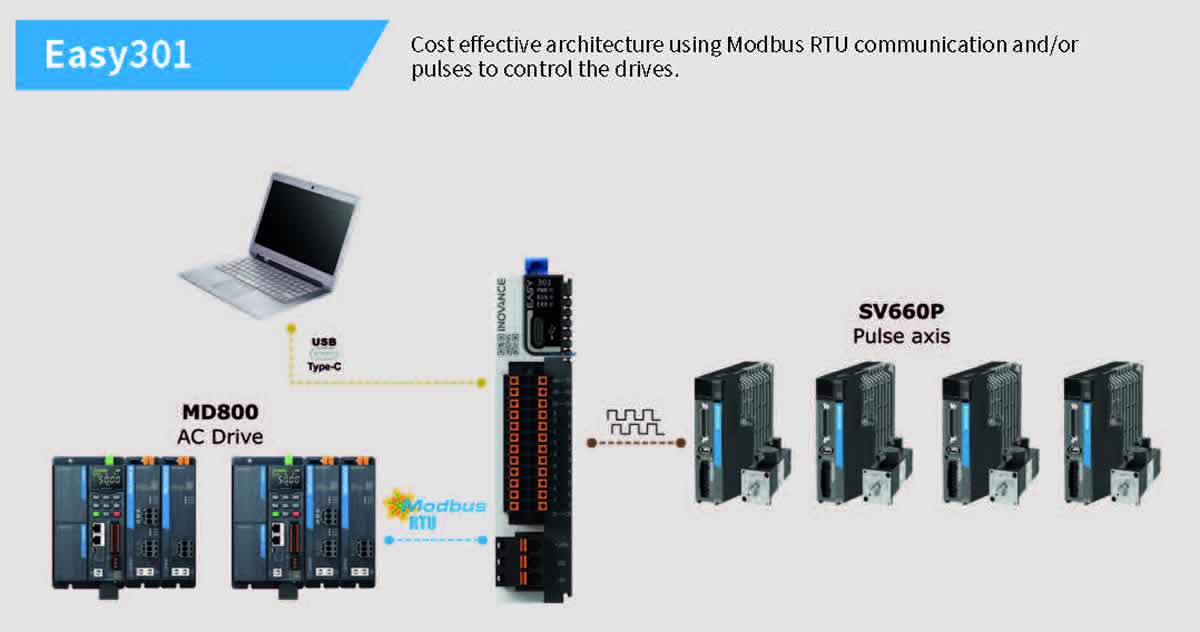

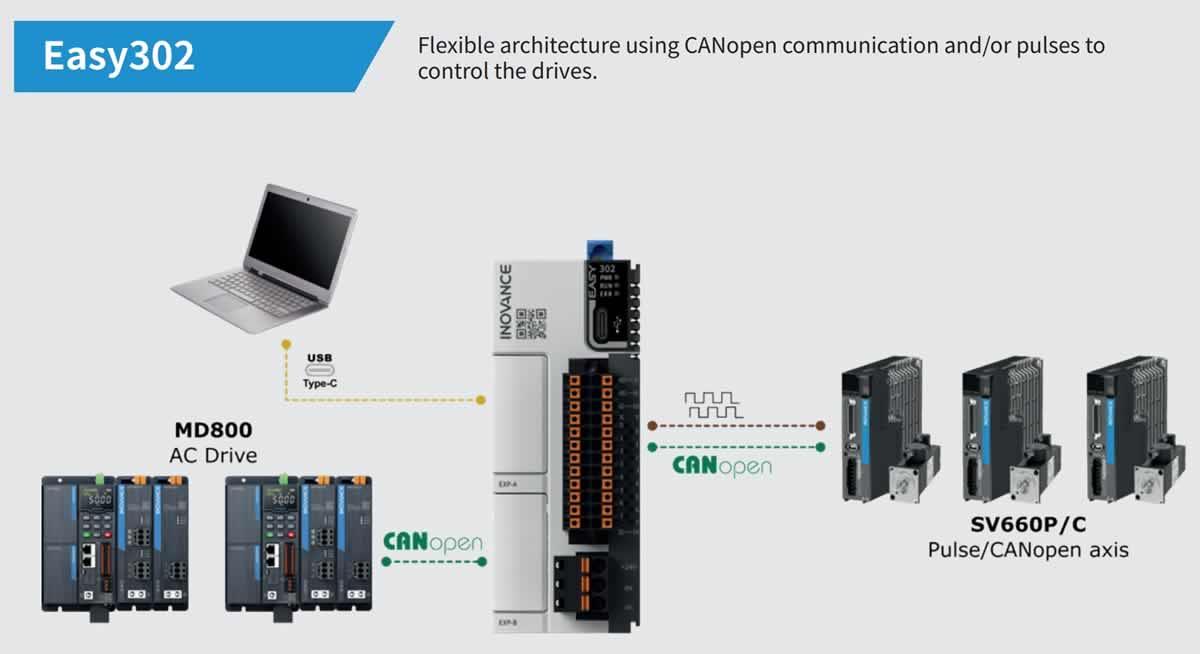

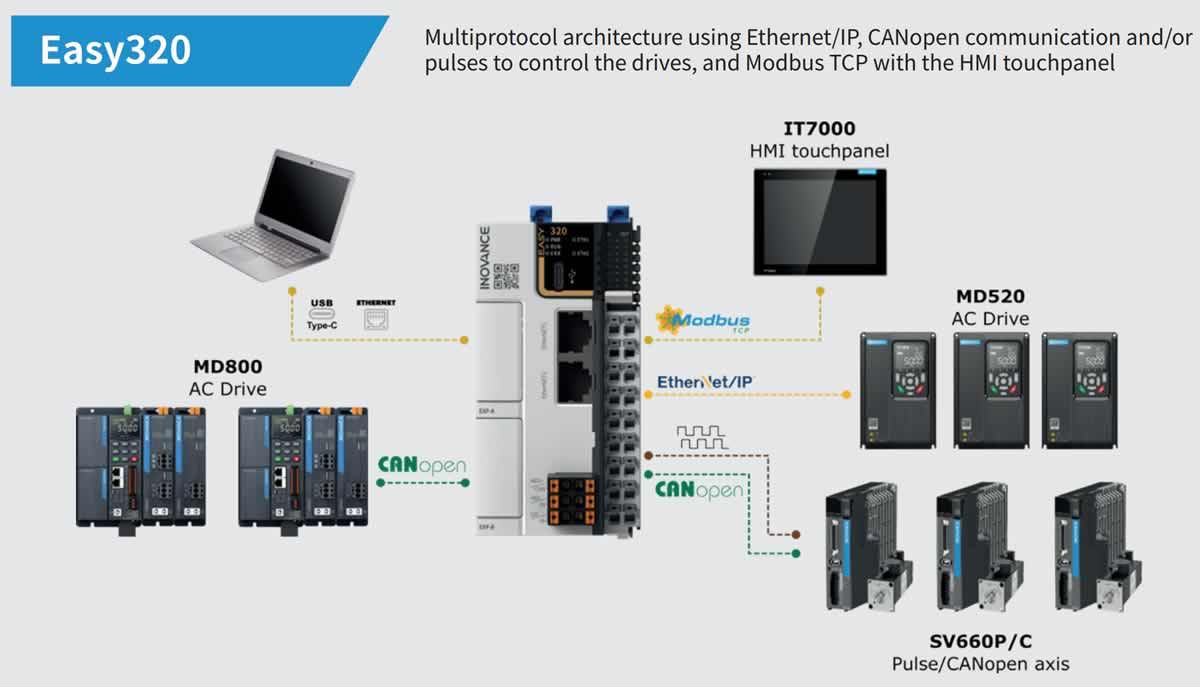

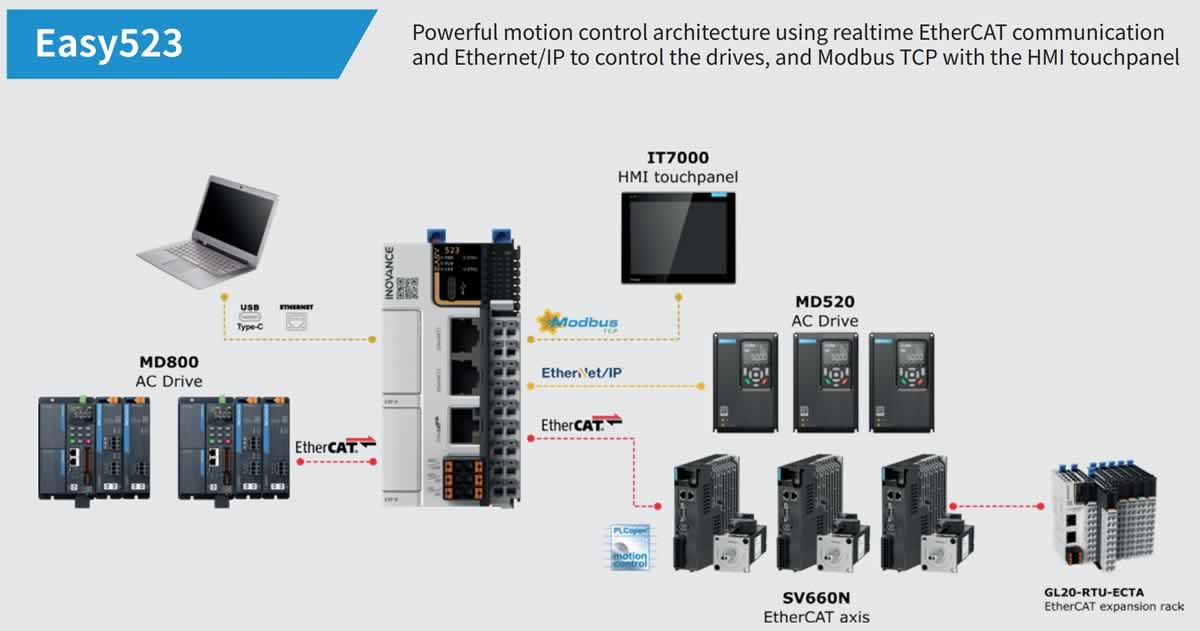

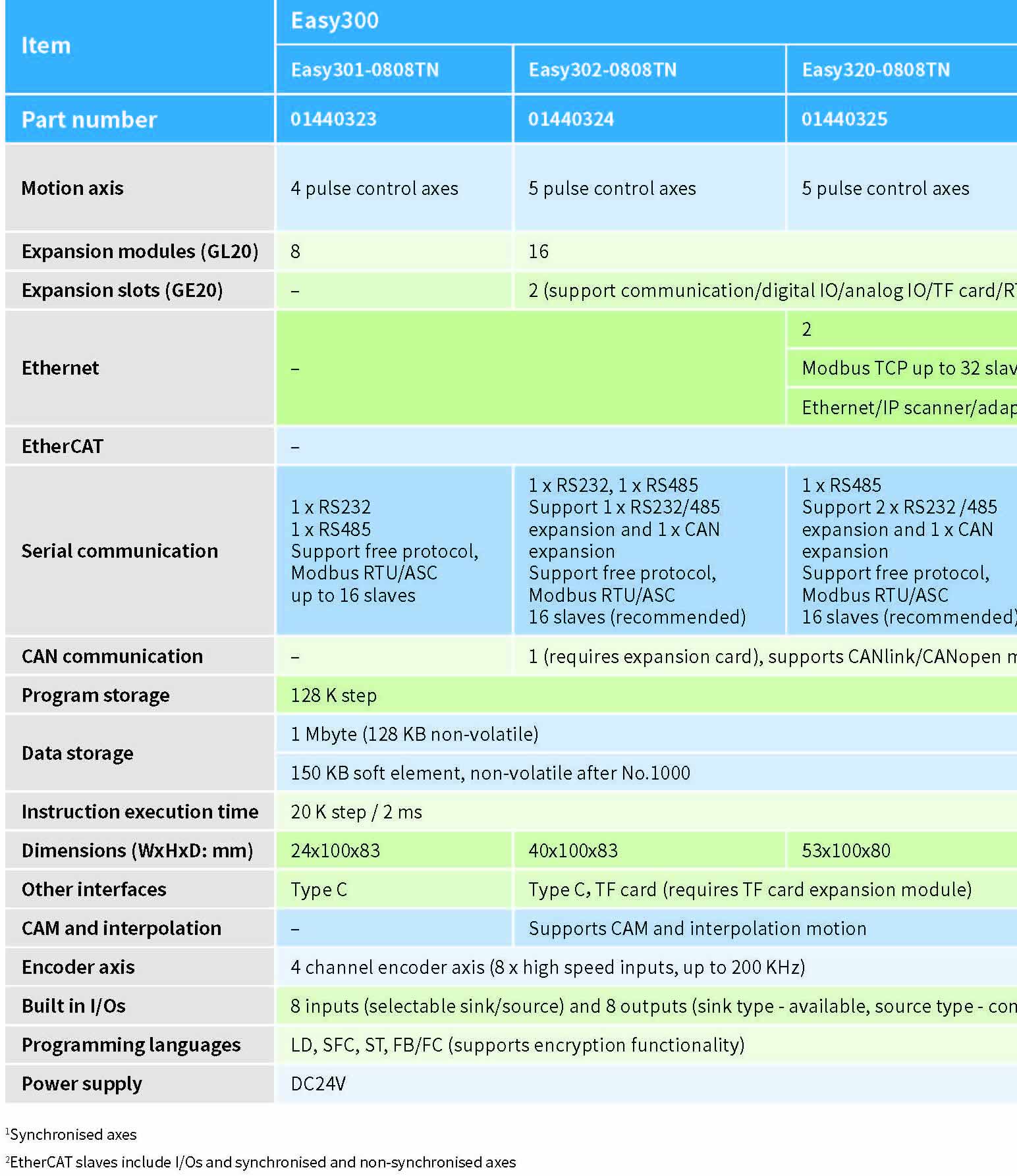

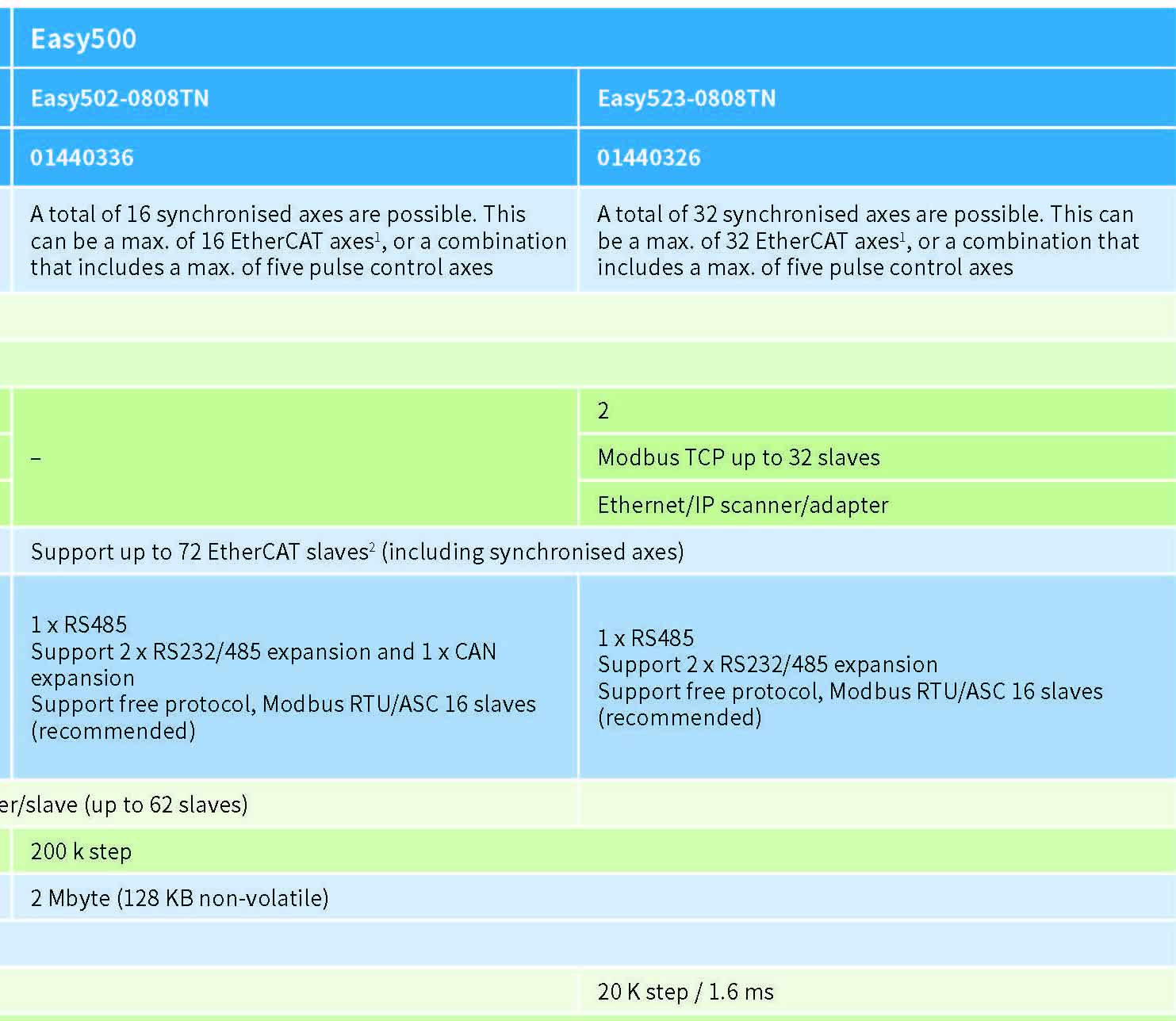

There are series Easy301, 302, 520, 502 & 523.

Easy301: Ultra compact CPU, RS232 + RS485

Easy302: General CPU, RS232 + RS485

Easy320: CPU with Ethernet, Dual Ethernet + RS485

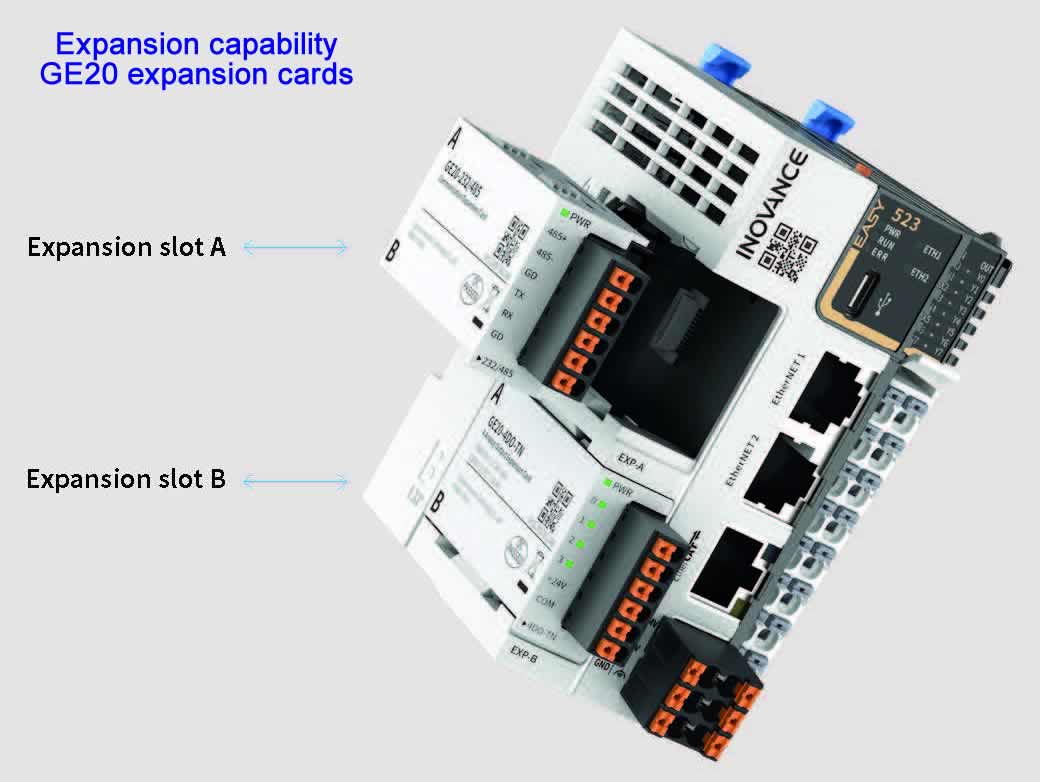

Easy502: Motion control CPU, EtherCAT + RS485

Easy523: Motion control CPU with Ethernet, Dual Ethernet+ EtherCAT + RS485

We have following advantages:

EASY programming: Customized FB/FC self defined variable programming assistant.

EASY assembly & wiring: Easy to add and/or replace modules. Plug in wires directly with spring clamp terminals.

EASY commissioning: Auto device scanning, easy configuration, servo debug without programming, offline simulation.

The type-C port works as a programming port allowing support programs, uploading/downloading and debugging.

Easy wiring with spring clamp terminals.

Slim and compact I/O expansion

Modules (GL20). Easy to plug in and remove for fast replacement.

Scalable system architecture & multiple configurations.

Communications capabilities:

RS485 connection - up to 31 slaves

CANopen - up to 62 slaves

CANlink - up to 62 slaves

Modbus TCP - up to 32 slaves (working as client/master)

Modbus TCP - up to 16 masters (working as server/slave)

Up to 3 serial ports (RS232/485) - 1 onboard and 2 GE20 expansion cards

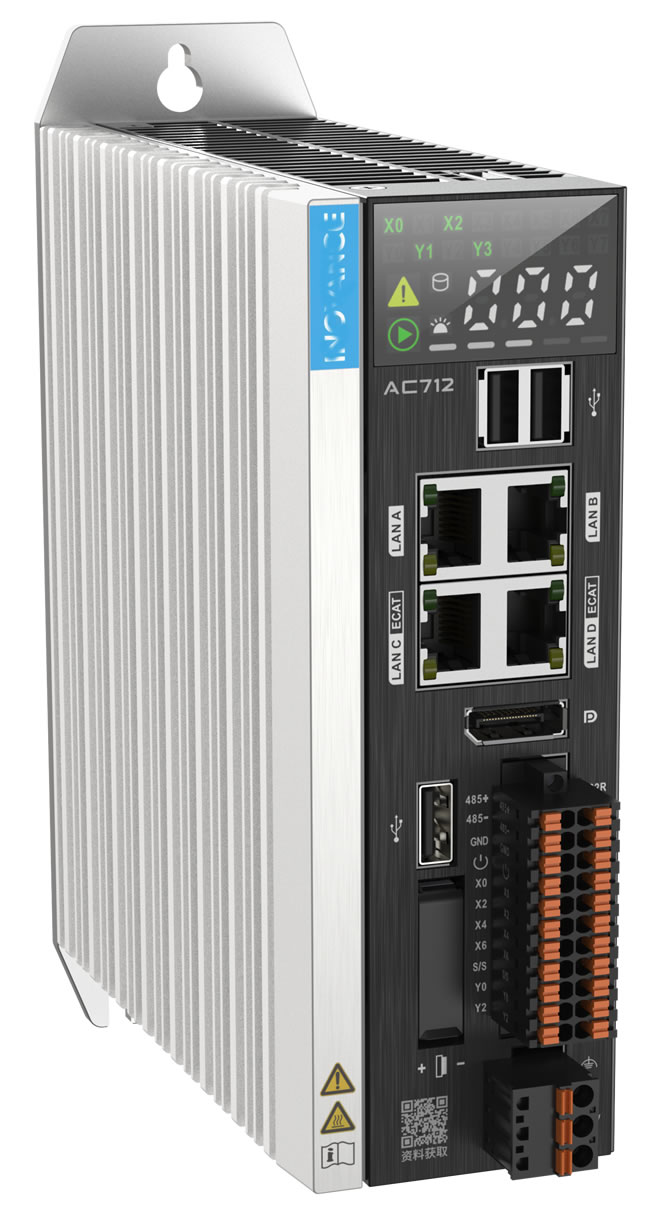

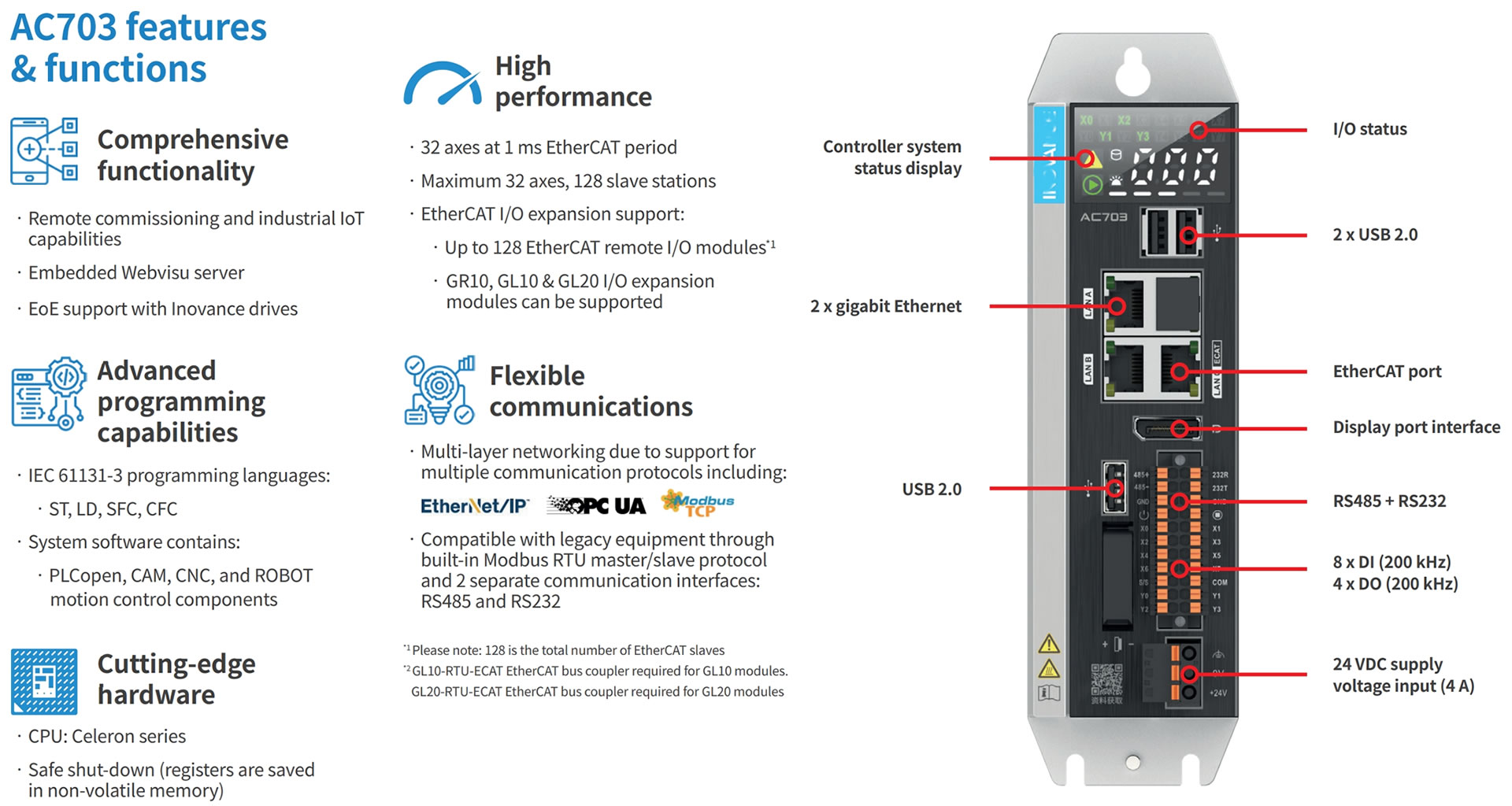

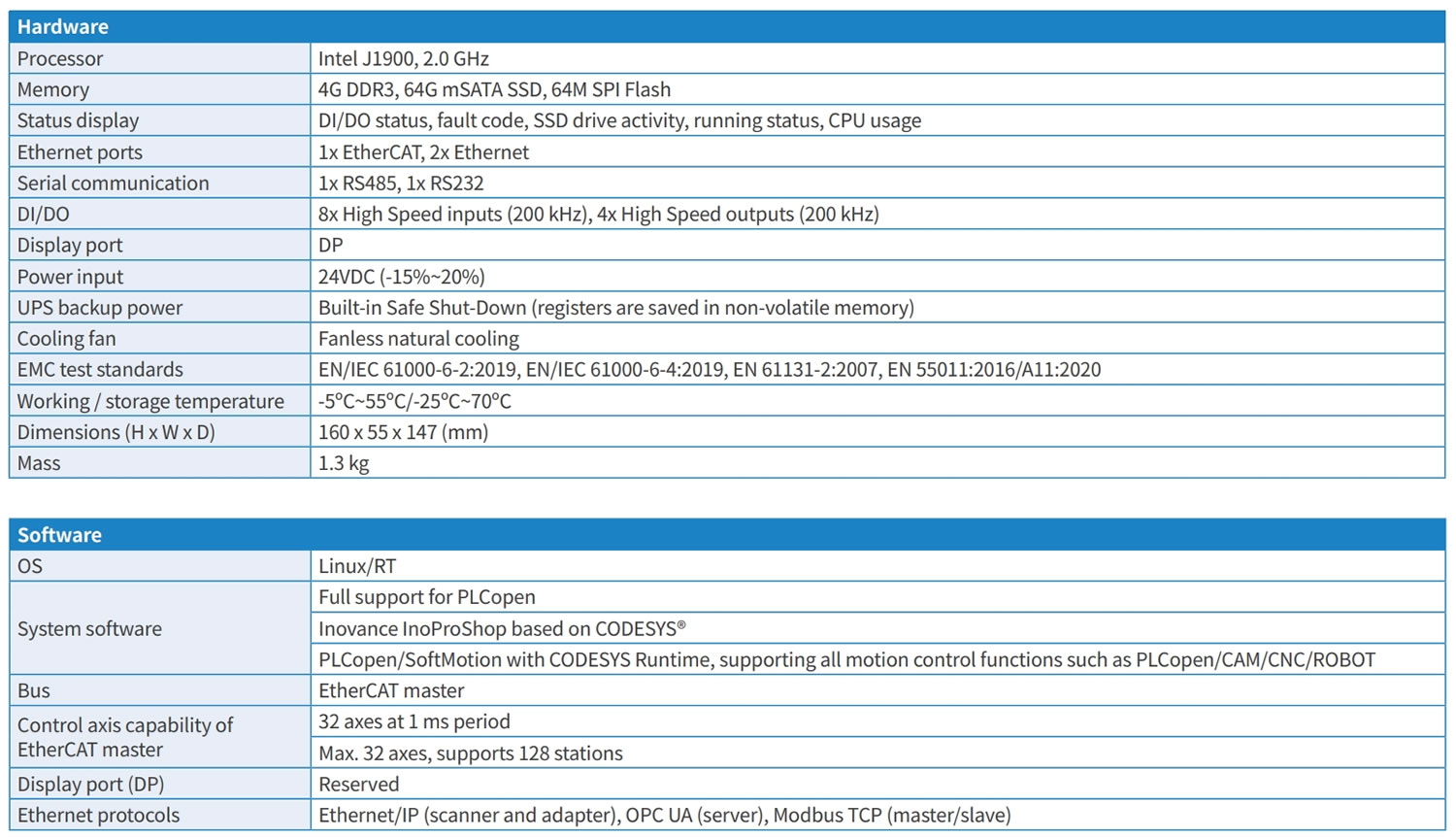

High Performance Intelligent Controller for demanding industrial applications

CPU: Intel Celeron J1900 2.0GHzz

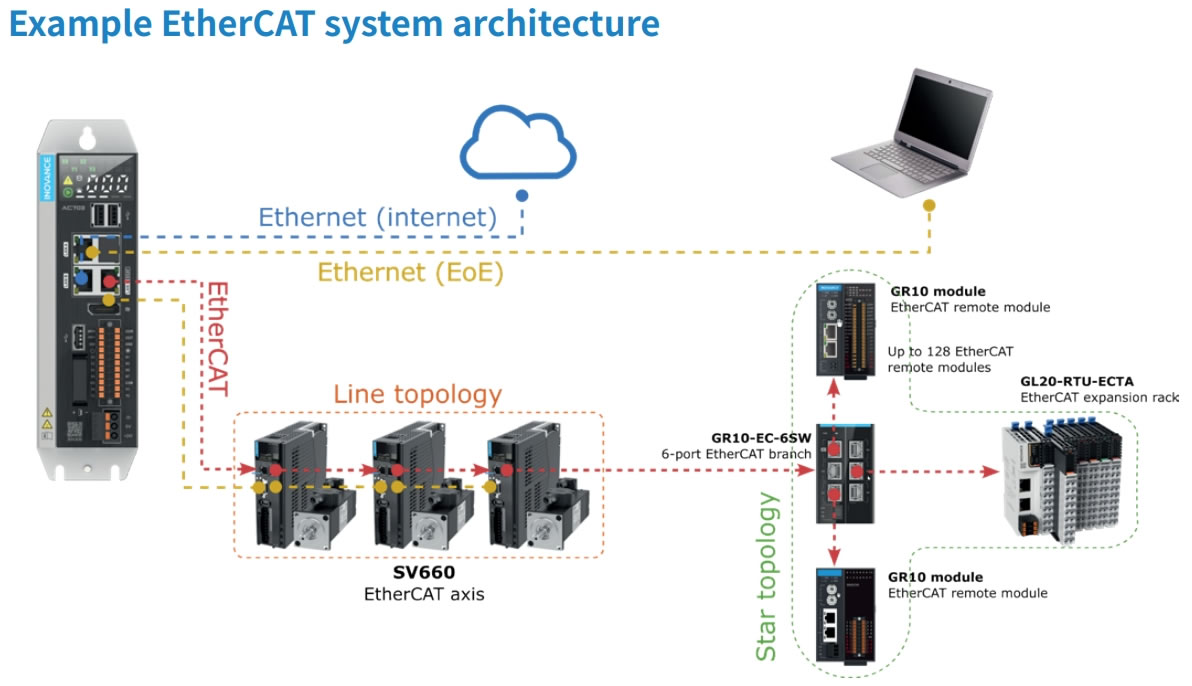

32 axes at 1 ms EtherCAT period: Maximum 32 axes, 128 slave stations; EtherCAT I/O expansion support. Up to 128 EtherCAT remote I/O modules

Multi-layer networking due to support for multiple communication protocols including: EtherCAT, Modbus TCP/RTU, Ethernet IP, OPC UA

Compatible with legacy equipment through built-in Modbus RTU master/slave protocol and 2 separate communication interfaces: RS485 and RS232

IEC 61131-3 programming languages: ST, LD, SFC, CFC

System software contains: PLCopen, CAM, CNC, and ROBOT motion control components

Remote commissioning and industrial IoT capabilities

Embedded Webvisu server

EoE support with SV660N drives

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 18 South Liu Fang Yuan Road, Sintec Industrial Park, Optics Valley of China, Wuhan Hubei, 430205 PR China

Mobile/Wechat: +86 19913132317

Whatsapp: +86 19913132317

E-mail: sales@SintecOptronics.cn