WhatsApp: +65 90013656 E-mail: sales@SintecOptronics.cn

WhatsApp: +65 90013656 E-mail: sales@SintecOptronics.cn

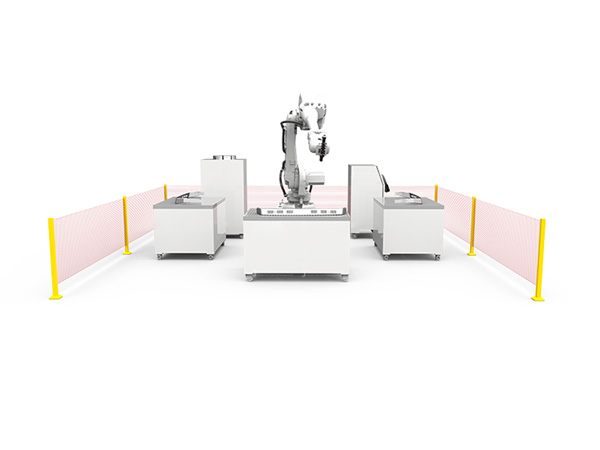

3D Six Axis Robot Laser Welding Machine can achieve 3D part processing; Robot laser welding has good adaptability to the shape of welded parts, and can weld any trajectory in spaces such as points, lines, circles, ellipses, and squares. It can perform spot welding, butt welding, overlap welding, and seal welding on workpieces, and can customize the extension axis to achieve circumferential welding. It also increases wire feeding function, providing perfect flexibility to meet the needs of comple

Adopting original imported industrial robots, with high positioning accuracy, wide processing range, and six axis linkage, it meets the needs of large stroke and high-precision spatial welding, and can achieve 3D part processing; Robot laser welding has good adaptability to the shape of welded parts, and can weld any trajectory in spaces such as points, lines, circles, ellipses, and squares. It can perform spot welding, butt welding, overlap welding, and seal welding on workpieces, and can customize the extension axis to achieve circumferential welding. It also increases wire feeding function, providing perfect flexibility to meet the needs of complex workpieces; It is very suitable for situations with high workload, high precision requirements, simplified processes, diverse workpieces, and complex surfaces. It is suitable for assembly line operations, automation integration, etc. It has no pollution to the environment, basically no spatter, is not easy to form welding scars, does not require secondary treatment, and is basically consumables free. It is mainly used for laser welding of automotive parts, bridge laser welding, and so on.

Adopting imported industrial robots with six axis linkage, high positioning accuracy, and large processing range;

Configure a weld seam tracking system for real-time detection and correction to ensure qualified welds are obtained;

Robots can be controlled through handles, enabling efficient operation even under harsh conditions;

High flexibility welding system, which can achieve automatic control and long-distance welding;

The core components are basically maintenance-free and have low usage costs;

Robot laser welding has good adaptability to welding materials, size and shape of welded parts;

The operation is simple and fast, with a rich process database embedded, which can be called or modified with one click;

Stable and reliable performance, efficient and energy-saving, low maintenance costs, and long service life;

Can design multi workstation collaborative work, rotating loading and unloading to improve production efficiency;

I currently have no information available,

Mainly used in scanning welding of electronic, 3C, optical communication, new energy batteries and other industries, it can achieve simultaneous spot welding and continuous welding of single or multiple lasers, and can achieve welding of various metal materials. For example, the welding of mobile communication, electronic components, glasses and watches, hardware and bathroom, medical equipment, automotive parts and other components can achieve spot welding, splicing welding, penetration welding, sealing welding, etc.

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 18 South Liu Fang Yuan Road, Sintec Industrial Park, Optics Valley of China, Wuhan Hubei, 430205 PR China

Tel: +86 27 51858962

Fax: +86 27 51858989

Mobile/Wechat: +86 13871137266

Whatsapp: +65 90013656

E-mail: sales@SintecOptronics.cn