Glass Laser Cutting Market Analysis

I. Market Overview

1. Global market status

In recent years, glass laser cutting technology has risen rapidly and has become an important part of modern manufacturing. According to market research firms, the global glass laser cutting market reached billions of dollars in 2023 and is expected to continue growing at a compound annual growth rate (CAGR) of approximately 8% over the next five years. Key drivers include increasing demand for high-precision cutting, continued growth in the construction industry, and the rise of smart home products.

2. Regional market analysis

- North American market: Benefiting from technological innovation and the concentration of high-end manufacturing, the North American market has a high demand for laser cutting technology, especially in the automotive and electronics industries.

- Europe market: The European region with its stringent quality standards and environmental regulations is driving the adoption of glass cutting technology, especially in the construction and high-end consumer goods sectors.

- Asia-Pacific: The Asia-Pacific region is the world's fastest-growing market, especially in China and India. With the acceleration of urbanization, the demand for glass in the construction industry continues to increase, and the laser cutting technology is gradually gaining importance.

II. Main Types of Glasses Used in the Market

In the glass laser cutting market, the main types of glass used each with its own characteristics, to adapt to different industry needs.

1. Float glass

Float glass is the most common construction material, its production process is simple, suitable for mass production. Due to its good optical properties and high flatness, it is widely used in windows, curtain walls and partitions. Laser cutting can realize precise size and complex shape to meet the needs of modern architectural design.

2. Tempered glass

Tempered glass is processed by heating and rapid cooling, and has extremely high strength and heat resistance, commonly used in automobiles, home appliances and high-grade furniture. Laser cutting enables efficient and fine cutting when processing tempered glass, ensuring that the cut glass has good physical properties.

3. Laminated glass

Laminated glass consists of multiple layers of glass and intermediate materials (e.g., PVB film), providing excellent safety and sound insulation. Its use in automobile windshields and building security windows is becoming more and more common. Laser cutting technology can precisely cut laminated glass to ensure its structural integrity and aesthetic appeal.

4. Art glass

Art glass is favored for its unique appearance and design, and is widely used in interior decoration and art production. Laser cutting technology can achieve complex patterns and meticulous craftsmanship to meet the needs of artists and designers, giving the glass works more creativity and personalization.

III. Main Ways of Glass Cutting and Comparison

In the glass processing industry, the choice of cutting method has a direct impact on production efficiency and quality of finished products. The following are several major cutting methods and their comparison:

1. Mechanical cutting

Mechanical cutting is the most traditional cutting method, using a knife to scribe a line on the surface of the glass, and then break along the scribed line. Although this method has simple equipment and low cost, it has obvious shortcomings in cutting accuracy, surface smoothness and material utilization.

Advantages and Disadvantages:

- Advantages:

o Low cost and suitable for small-scale production.

o Simple equipment maintenance.

- Disadvantages:

o Lower cutting precision, difficult to handle complex shapes.

o It is easy to cause glass edge breakage, which affects the aesthetics.

2. Waterjet cutting

Waterjet cutting uses high-pressure water flow and abrasive cutting, which can realize high cutting precision and is suitable for handling various materials, including metal and glass. This method is characterized by a smooth cutting surface and is particularly suitable for cutting complex shapes.

Advantages and Disadvantages:

- Advantages:

o Smooth cutting surface with virtually no heat-affected zone.

o Can handle a wide range of materials and is suitable for a wide range of applications.

- Disadvantages:

o Higher equipment costs and high operating costs.

o Relatively slow speed and limited productivity.

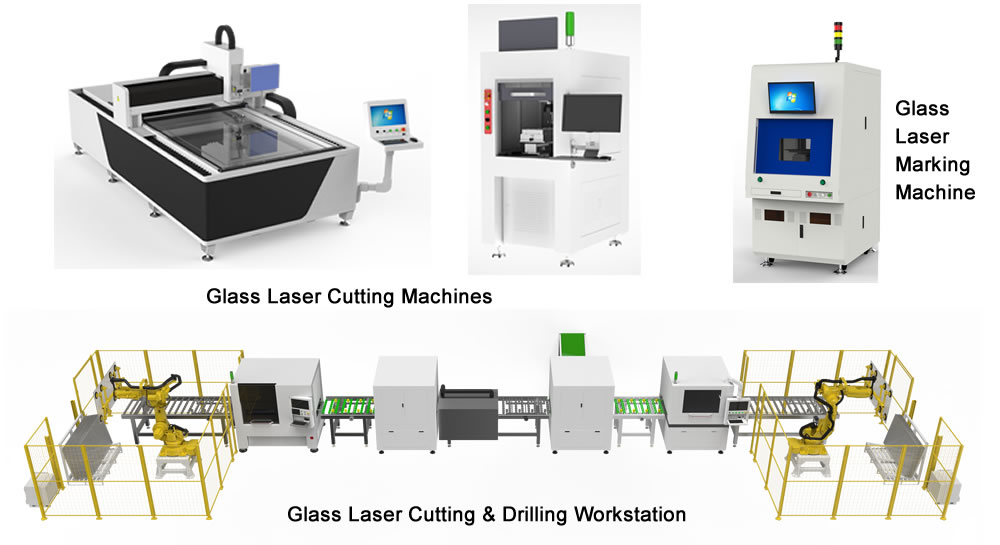

3. Laser cutting

Laser cutting is currently the most advanced cutting technology, through the high-energy laser beam on the material to carry out accurate cutting, with very high cutting speed and precision. Laser cutting is suitable for a wide range of thicknesses and types of glass and is capable of handling complex patterns.

Advantages and Disadvantages:

- Advantages:

o High accuracy and efficiency for mass production.

o No contact during the cutting process, reducing physical damage to the material.

o Flexibility, allowing cutting parameters to be quickly adjusted to suit different needs.

- Disadvantages:

o Higher initial equipment investment.

o Higher technical requirements for operators.

Comparison table of several cutting methods

Table: Comparison of Cutting Methods

Cutting methods | Advantages | Disadvantages |

Mechanical cutting | Low cost, simple equipment | Low precision, easy to break |

Waterjet cutting | Smooth cutting surface, wide range of applications | High cost, slow speed |

Laser cutting | High precision, high efficiency, non-contact processing | High initial investment, high technical requirements |

IV. Principle and Advantages of Glass Laser Cutting

1. Basic principle of laser cutting

The principle of glass laser cutting is based on the high energy density of the laser beam. When the laser beam irradiates the glass surface, the laser energy will be rapidly absorbed by the glass, resulting in a sharp rise in temperature. The heat of the laser beam causes the glass to melt or evaporate in an instant, forming the cutting line. Subsequently, the molten material is blown away by an auxiliary gas (e.g. nitrogen or oxygen), resulting in high-precision cutting.

2. Technical parameters of laser cutting

During the laser cutting process, several key technical parameters directly affect the cutting effect:

- Laser power: the higher the power, the faster the cutting speed, but may also lead to excessive thermal effects.

- Cutting speed: too fast may lead to incomplete cutting, while too slow may lead to material overheating.

- Focal length: Adjustment of the focal position can affect the accuracy and quality of the cut.

- Gas pressure: the pressure of the auxiliary gas can affect the removal of molten material.

3. Advantages of laser cutting

- High precision: laser cutting technology can achieve micron-level cutting accuracy to meet the needs of high-end products.

- Fast cutting speed: laser cutting is relatively fast, which significantly improves the production efficiency and reduces the production cycle.

- Strong material adaptability: Whether it is thin glass or thick glass, laser cutting can be competent, and can flexibly cut various shapes and patterns.

- Non-contact processing: laser cutting is non-contact processing, does not cause mechanical stress on the material, reducing the risk of physical damage and breakage.

- Environmental protection: laser cutting process is almost no waste generated, reducing the burden on the environment.

V. Application Cases of Laser Cutting in Various Industries

1. Construction industry

In the construction industry, glass, as an important building material, is widely used in curtain walls, windows and partitions. Laser cutting technology can realize a variety of complex shapes and designs to enhance the aesthetics and functionality of the building. For example, the glass curtain walls of some high-grade office buildings adopt laser cutting technology, which ensures the accuracy of size and diversity of shapes.

2. Automobile industry

The automotive industry has extremely strict requirements for glass, especially windshield and side window glass. Laser cutting technology can realize high-precision cutting in the production of tempered glass, which improves the safety and comfort of automobiles. Modern automotive design tends to use large areas of glass, and the flexibility of laser cutting allows designers to create a more visually appealing appearance.

3. Electronics industry

In the electronics industry, glass is widely used in displays and touch screens. Laser cutting enables the cutting of extremely small sizes and complex patterns, ensuring high quality and precision in displays. With the development of 5G and smart devices, the demand for glass cutting technology will further increase.

4. Home decoration

In the field of home decoration, the demand for art glass and decorative glass continues to rise. Laser cutting technology can produce a variety of unique patterns and designs to meet consumers' personalized needs. For example, customized laser-cut glass partitions and wall decorations are becoming increasingly popular as home design

VI. Conclusion

With the development of science and technology, glass laser cutting technology will show its potential in more fields. High precision, high efficiency and good adaptability make it an indispensable cutting method in modern industry. With the increase in market demand, the future of laser cutting technology will certainly usher in a broader space for development.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்