Innovation of Laser Robot Cutting Technology for Electric Vehicle Frame Parts

In this era of pursuing efficiency and precision, every technological innovation is like injecting a strong vitality into the manufacturing industry. The laser robot 3D cutting technology launched by Honglei Laser, which cuts electric bicycle frame parts, is bringing a disruptive technological revolution to the field of sports equipment pipe processing with its unprecedented advantages, making the future of "smart manufacturing" within reach.

At present, most bicycle frames are made of pipes, which have the following two advantages: first, relatively light weight; second, pipes have a certain strength. The majority of pipe materials used for bicycles are aluminum alloy, titanium alloy, chromium molybdenum steel, carbon fiber, etc. Improving pipe and structural design capabilities and innovating processing technologies have become an eternal melody for the innovative development of the bicycle industry.

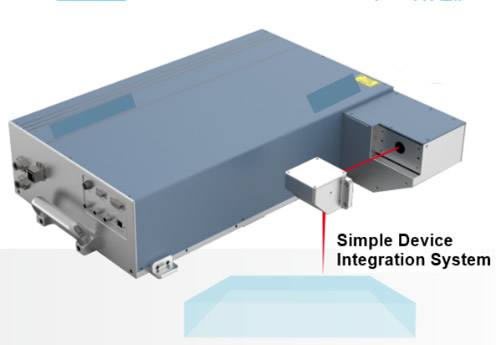

Bicycle fittings are an important technological innovation in the field of modern bicycle manufacturing. This device uses laser technology to efficiently and accurately cut bicycle fittings, greatly improving the efficiency and quality of bicycle manufacturing.

Imagine a perfect encounter between industrial robots and laser technology, where they join forces to perform not only a technological feast, but also a profound transformation of traditional processing modes. The cutting tasks of pipe fittings that used to require multiple processes and time-consuming labor can now be easily completed with just a gentle touch. The cut is as smooth as a mirror, without any subsequent polishing, and can directly enter the next process, greatly shortening the production cycle. Achieved a one-time leap in processing technology.

What's even more amazing is that this laser robot 3D cutting solution, like a precise surgical knife, not only has excellent cutting quality - the incision width is extremely narrow, the heat affected zone is minimal, the surface is smooth as new, but also has amazing speed and full flexibility. It can handle complex geometric shapes and diverse types of materials with ease and ease. This not only improves the overall quality of the product, but also allows designers' creativity to be freely realized.

The previously tedious process of cutting and trimming has now become both fast and efficient, greatly improving the flexibility and response speed of the production line. Especially in the current era of frequent vehicle model changes, Honglei Laser's 3D laser cutting robot has demonstrated its unparalleled advantages. By simply adjusting the laser processing program without changing the mold, it can quickly adapt to the production needs of new car models. The tooling is simple, the construction period is greatly shortened, and the cost is sharply reduced, truly realizing the heroic goal of "one machine in hand, I have it all".

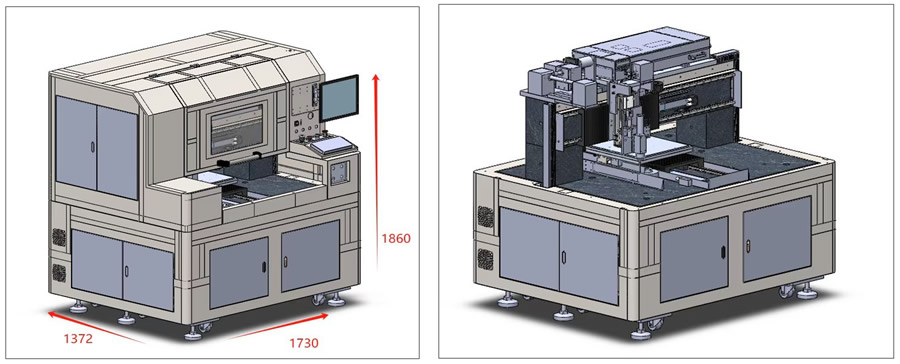

In addition, from an economic perspective, the application of laser robot 3D cutting technology has brought tangible benefits to enterprises. It not only reduces labor costs and initial investment such as mold costs, but also saves a lot of expenses for enterprises by improving efficiency, reducing energy consumption, and decreasing maintenance costs. More importantly, it occupies a small area, providing more flexible layout possibilities for modern factories that value every inch of land.

In summary, the emergence of Honglei laser robot 3D cutting technology is not only a comprehensive upgrade to traditional processing methods, but also a profound exploration of future intelligent manufacturing. It is driving the sports equipment and pipe fittings processing industry towards higher, faster, and stronger directions with the power of technology, opening a new chapter in intelligent manufacturing.

The 3D robot cutting machine has significant technical advantages in cutting bicycle pipe fittings. Firstly, it has fast cutting speed, high efficiency, and can achieve mass production, thus meeting the demand for efficient production in the bicycle manufacturing industry. Secondly, 3D laser cutting has high precision, stable cutting quality, no need for secondary processing, reduces production costs, and improves product quality. In addition, the 3D laser cutting machine is easy to operate, highly automated, reduces manual intervention, and improves production efficiency.

In summary, the 3D robot laser cutting machine has brought revolutionary changes to the bicycle manufacturing industry with its high efficiency, precision, and automation characteristics. With the continuous development of technology, it is believed that 3D laser cutting technology will play a greater role in the field of bicycle manufacturing and promote the continuous progress of the bicycle industry.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்