WhatsApp: +65 90013656 E-mail: sales@SintecOptronics.cn

WhatsApp: +65 90013656 E-mail: sales@SintecOptronics.cn

The high-precision fiber laser cutting machine has the characteristics of high single machine processing efficiency, complete dust free, stress free, burr free, and smooth and neat cutting edges. One time cutting and forming, without the need for mold development and secondary grinding processing, the process is simple, reducing labor and time investment costs. Compared with traditional stamping and forming, the processing cost of a single workpiece is lower, the efficiency is increased by more

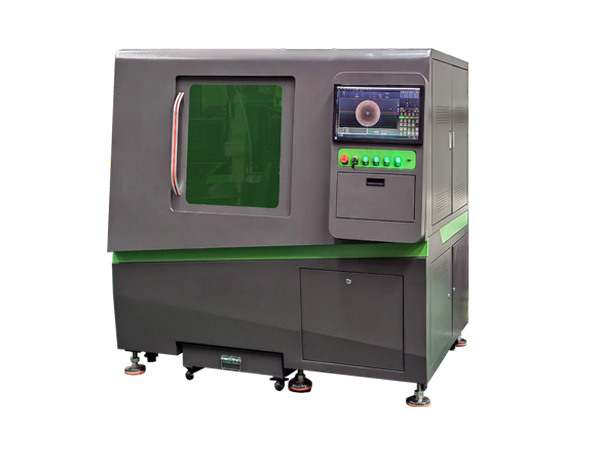

High precision fiber laser cutting machine is a high-end fiber laser cutting and processing system that integrates advanced fiber laser technology, numerical control technology, and precision mechanical technology. It is a perfect fusion of laser technology and numerical control technology, representing a leading level of cutting and processing. It is equipped with an independently developed precision cutting control system, with continuous and fast curve cutting functions and the shortest processing path optimization function, which is not affected by the shape of the workpiece, It can process any shape, with smooth and beautiful cutting seams. It can perform precise cutting of any shape on small workpieces, making your production process simpler and more efficient. The high-precision fiber laser cutting machine has the characteristics of high single machine processing efficiency, complete dust free, stress free, burr free, and smooth and neat cutting edges. One time cutting and forming, without the need for mold development and secondary grinding processing, the process is simple, reducing labor and time investment costs. Compared with traditional stamping and forming, the processing cost of a single workpiece is lower, the efficiency is increased by more than twice, and the subsequent maintenance cost is only 1/3 to 1/4 of the same efficiency CNC punch. It can be applied to sapphire, ceramics, silicon, and various metal sheets to quickly achieve precision cutting, punching, chamfering, and surface treatment. It is widely used in industries such as precision machinery and hardware that require high cutting accuracy.

Strong adaptability to materials, able to adapt to the cutting and processing of various irregular small hardware parts;

High production efficiency, which can replace traditional manufacturing processes such as CNC punching, shearing, and manual work;

Fast cutting speed, no edge collapse phenomenon, no damage to the workpiece, with a high yield rate;

High cutting accuracy, smooth cut surface without burrs, good verticality, and no need for subsequent secondary processing;

The operation is simple and fast, with a rich process database embedded, which can be called or modified with one click;

Stable and reliable performance, efficient and energy-saving, low maintenance costs, and long service life;

Various non-standard models and fully automatic feeding devices can be customized to shorten the feeding time;

Green and environmentally friendly processing, no pollutants, no consumables, and high yield rate;

Model STC-XXXX-YY-AABB

| STC | XXXX Laser power (W) | YY model | AA X-axis stroke | BB Travel Y-axis |

| laser cutting | one thousand and five hundred | LS: Screw guide rail | 04:400mm | 04:400mm |

| two thousand | LM: Linear motor | 06:600mm | 06:600mm | |

| three thousand | ||||

| Q150: QCW150W | ||||

| Q300: QCW300W | ||||

| Q450: QCW450W |

| Laser generator | High performance anti high reflection fiber laser |

| Laser power | QCW: 150W/300W/450W; CW: 1500W/2000W/3000W |

| X.Y-axis positioning accuracy | Linear motor: ± 0.003mm; Screw rod: ± 0.02mm |

| Repetitive positioning accuracy | Linear motor: ± 0.005mm; Screw rod: ± 0.03mm |

| Maximum positioning speed of the machine tool | 100m/min |

| Cutting width | 0.05-0.1mm |

| Processing format | 600mm * 600mm, customizable |

| Z-axis travel | 100mm |

| acceleration | 2G |

| Platform material | Grade 00 marble |

| Maximum cutting speed and thickness | 0.05-3.0mm stainless steel plate, 45, 20Cr |

| Maximum air travel speed | 100m/min |

| Overall power | 11KW |

| Continuous working hours | 24 hours |

| Cooling method | water-cooling |

| Power requirements | Three phase five wire system AC380V 50HZ |

| Equipment size | Dual drive: 1820 * 1450 * 1780mm; Single drive: 1400 * 1400 * 1850mm |

Remarks:

1.1 The above parameters are based on the 150W QC W laser and 6060 dual drive cutting cabinet, which can be customized non-standard according to customer requirements. The configuration and parameters of each model are subject to the technical solution provided by our company; 2. Although the processed workpiece belongs to the same specification variety, there may be differences in processing performance and quality due to differences in actual processing parts, surface conditions, material composition, or processing shapes; 3. The positioning accuracy is greatly affected by environmental temperature, and repeated positioning accuracy may be affected by electrical interference, control system errors, etc., resulting in a certain degree of deviation (≤ 1 μ m) .

Mainly designed for high-precision micro hole cutting of various metal sheets below 5mm, it is particularly suitable for precision cutting of metal materials such as stainless steel, aluminized zinc plate, silicon steel, alloy steel, copper, and non-metallic brittle materials such as sapphire, ceramics, wafer, etc. It is widely used in industries such as 3C electronics, medical equipment, military industry, aerospace, metal crafts, gold and silver jewelry, hardware products, precision machinery, automotive parts, glasses, and saw blades.

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 18 South Liu Fang Yuan Road, Sintec Industrial Park, Optics Valley of China, Wuhan Hubei, 430205 PR China

Tel: +86 27 51858962

Fax: +86 27 51858989

Mobile/Wechat: +86 13871137266

Whatsapp: +65 90013656

E-mail: sales@SintecOptronics.cn