WhatsApp: +65 90013656 E-mail: sales@SintecOptronics.cn

WhatsApp: +65 90013656 E-mail: sales@SintecOptronics.cn

Laser cleaning is a new technology based on the interaction of laser and material, which can achieve the effect of removing surface pollution and attachment. Compared with traditional cleaning methods, laser cleaning has the advantages of non-contact, no damage to the substrate, accurate clean

Laser cleaning is a new technology based on the interaction of laser and material, which can achieve the effect of removing surface pollution and attachment. Compared with traditional cleaning methods, laser cleaning has the advantages of non-contact, no damage to the substrate, accurate cleaning , 'green' environmental protection and on-line, especially suitable for high-speed on-line cleaning in designated areas. The laser cleaning equipment produced by our company is a new generation of high-tech products for surface treatment, which is easy to install, control and realize automation. Simple operation, power supply, open equipment, can be no chemical reagent, no medium, no dust, no water cleaning, can fit surface cleaning, cleaning surface cleanliness is high, can remove object surface resin, paint, oil stains, dirt, rust, coating, coating and oxidation layer, and the industry is widely used, covering ships, auto repair, rubber mold, high-end machine tools, tracks and environmental protection.

Features:

l Non-contact cleaning without damaging the matrix of the parts;

l Accurate cleaning, can achieve precise position, accurate size selective cleaning;

l Do not need any chemical cleaning liquid, no consumables, safety and environmental protection;

l Simple operation, hand-held or with the manipulator to achieve automatic cleaning;

l Ergonomics design, operating labor intensity greatly reduced;

l Trolley design, with its own moving wheel, easy to move;

l High cleaning efficiency, save time;

l Laser cleaning system is stable with little maintenance;

Technical Specifications:

Supply voltage | Single phase 220V±10%, 50/60Hz AC |

Power consumption | ≤800W |

Working environment temperature | 5℃~40℃ |

Working environment humidity | ≤80% |

Average laser power | ≥100W |

Power instability | <5% |

Laser Working Mode | Pulse |

Maximum monopulse energy | 1.5mJ |

Power regulation range | 0-100% (Gradient Adjustable) |

Repeat frequency | 1-3000kHz (Gradient Adjustable) |

Fiber length | 5m |

Cooling mode | Air cooling |

San range | Uniaxial: 0mm-100mm, continuously adjustable; |

Biaxial: supporting 8 scanning modes | |

Scanning frequency | The maximum is not less than 300Hz |

Field mirror focal length | 160mm(Optional 10mm/254mm/330mm/420mm) |

Depth of focus | About 5 mm |

Mode of operation | Handheld/automated |

Application industry:

l Marine automotive parts

l Rubber mold

l High-end machine tool

l Tire mold

l Track environmental industry

l Other

l Printing Shops,

l Manufacturing Plant,

l Food & Beverage Factory,

l Farms

l Hotels,

l Home Use,

l Garment Shops,

l Construction works ,

l Machinery Repair Shops,

l Advertising Company,

l Energy & Mining,

l Building Material Shops

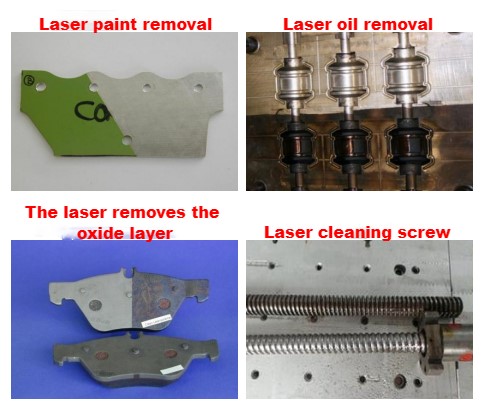

Applied range samples:

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 18 South Liu Fang Yuan Road, Sintec Industrial Park, Optics Valley of China, Wuhan Hubei, 430205 PR China

Tel: +86 27 51858962

Fax: +86 27 51858989

Mobile/Wechat: +86 13871137266

Whatsapp: +65 90013656

E-mail: sales@SintecOptronics.cn