WhatsApp: +65 90013656 E-mail: sales@SintecOptronics.cn

WhatsApp: +65 90013656 E-mail: sales@SintecOptronics.cn

The advantages of air-cooled handheld laser welding machines mainly include the following points:l Compact size and strong portability: Its size is similar to that of a computer host, so it is very suitable for on-site operations in terms of operation. On site operations or occasions that requ

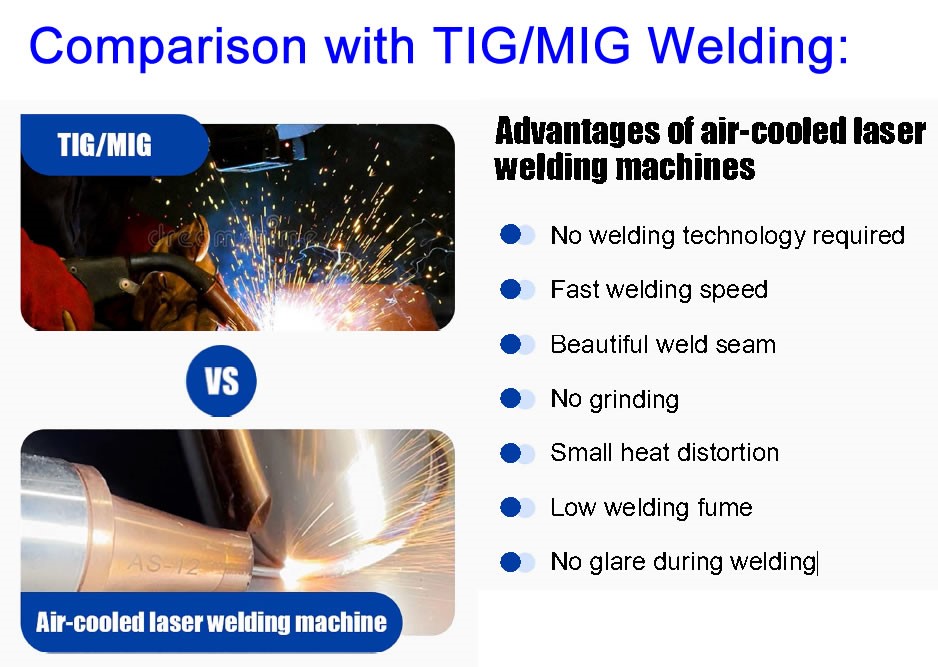

The advantages of air-cooled handheld laser welding machines mainly include the following points:

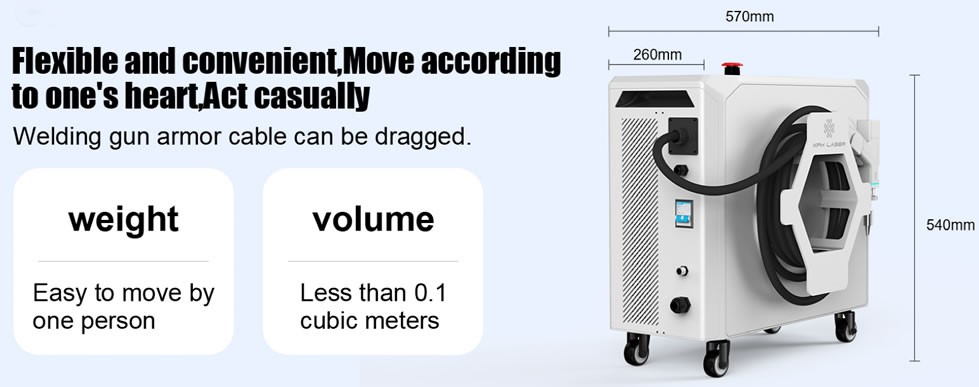

l Compact size and strong portability: Its size is similar to that of a computer host, so it is very suitable for on-site operations in terms of operation. On site operations or occasions that require mobile welding.

l Multiple power options available: offers three power options, 700W, 1200W and 1500W, which can adapt to different welding needs, whether it is precision welding or welding of thicker materials.

l Wide welding thickness range: 700W of power is suitable for welding with a thickness of 0.4 to 3 mm, while 1500W of power can handle materials with a thickness of 0.4 to 5mm, covering the most common welding needs.

l Easy to operate: Simply press to start welding, suitable for operators with different skill levels.

l Accurate control of welding parameters: capable of accurately controlling key parameters during the welding process, ensuring welding quality, and meeting high standard welding requirements.

These advantages make air-cooled handheld laser welding machines efficient, flexible, and reliable welding tools, suitable for various industrial and manual welding scenarios.

Technical Specifications

Model Number | SXF-700W | SXF-1200W | SXF-1500W |

Laser power | 700W | 1200W | 1500W |

Dimension | 570x260x540mm | 570x260x540mm | 570x260x540mm |

Weight | 29kg | 43kg | 48kh |

Max. power required | 2.5kW | 4kW | 4.5kW |

Input voltage | 220VAC, 50/60Hz | 220VAC, 50/60Hz | 220VAC, 50/60Hz |

Cooling method | Air-cooled | Air-cooled | Air-cooled |

Operation temp. | -20 ~ 40 degree C | -20 ~ 40 degree C | -20 ~ 40 degree C |

Laser wavelength | 1070nm | 1070nm | 1070nm |

Welding handle length | 10m | 10m | 10m |

Welding speed | 0-2m/min | 0-2m/min | 0-2m/min |

Welding thickness | 0.4-3mm | 0.4-4mm | 0.4-5mm |

Scan width | 0-8mm | 0-8mm | 0-8mm |

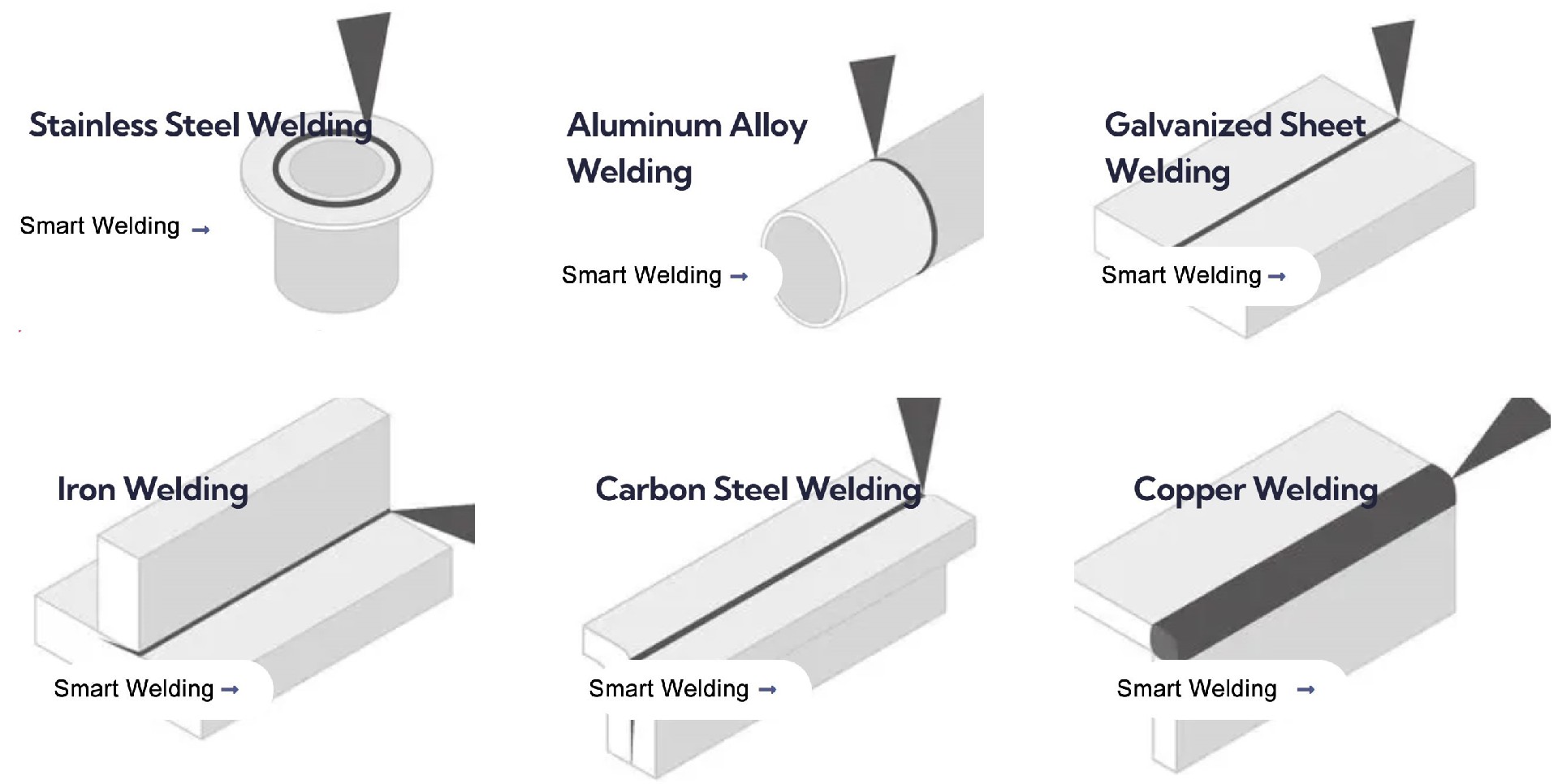

Welding material | Carbon steel, stainless steel, aluminum, galvanized material & other metal materials | ||

Pointing light | Red light | Red light | Red light |

Capable of functionality | Welding, cutting, cleaning | ||

Adapted welding wire dia. | 0.8/1.0/1.2/1.6/2.0mm | ||

Automatic wire feeding | Standard configuration | ||

Welding wire specs. | Solid coiled wire, same as gas-shielded wire | ||

Welding wire material | Same as welded base material | ||

Protective gas | Nitrogen, argon, carbon dioxide | ||

Protective gas flow rate | 10-15 liters per minute | ||

Packing List

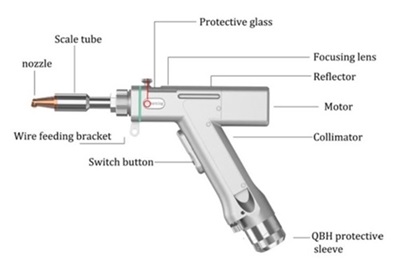

1) Laser welding machine, including 10m of welding wire, one unit

2) Wire feeder, including wire feed tube, wire feed wheel accessories, one set

3) Safety goggles, one pair

4) Welding nozzle, five pcs

5) Protective lens, 18*2, five pcs (disposables)

6) Nozzle assembly, including 0.8/1.0/1.2/1.6mm wire nozzle and wire feeder, one set

7) Protective gas connection fittings, one piece

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 18 South Liu Fang Yuan Road, Sintec Industrial Park, Optics Valley of China, Wuhan Hubei, 430205 PR China

Tel: +86 27 51858962

Fax: +86 27 51858989

Mobile/Wechat: +86 13871137266

Whatsapp: +65 90013656

E-mail: sales@SintecOptronics.cn