Picosecond Glass Cutting in Life

The figure of glass can be seen everywhere in our daily life, from small cell phone screens and drinking glasses to large automobile glass and skyscrapers. Every piece of glass you can see is likely to be closely related to industrial laser technology.

Despite the many advantages of glass material, its fragile characteristics bring a lot of difficulties to the processing, such as easy to crack, rough edges and so on. The traditional glass cutting process is plagued with brittleness, high hardness, poor heat dissipation, large coefficient of thermal expansion, and large amount of chipping. How to solve the processing problems of glass materials and improve the yield rate has become a common goal in the industry.

Glass laser cutting is an easy-to-control, non-contact, less-polluting cutting technology that guarantees the advantages of neat edges, good perpendicularity and low internal damage at high cutting speeds. Especially for high-precision cutting, picosecond ultra-fast lasers show great advantages due to their extremely narrow pulse widths. Utilizing the characteristics of low heat diffusion, the material interruption is completed before heat conduction to the surrounding material, which shows good results in the cutting of brittle materials. With the development of laser technology, glass cutting also appeared in the figure of the laser.

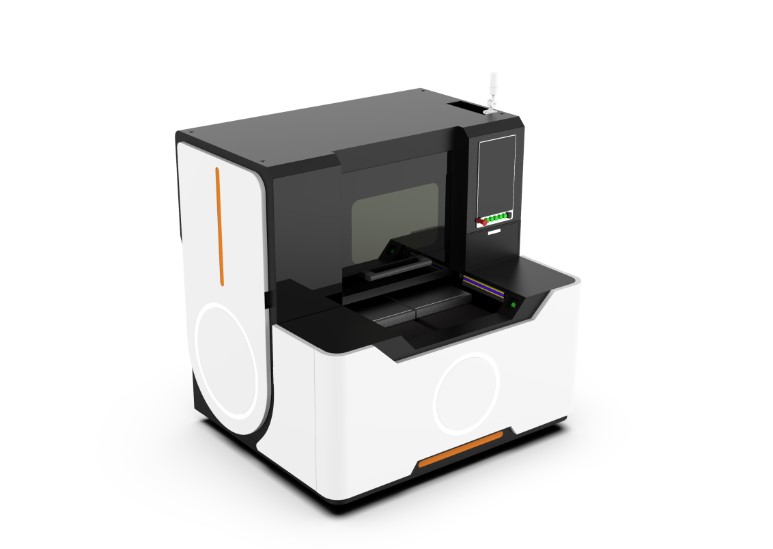

Wuhan Sintec Optronics independent research and development of infrared picosecond glass cutting products once the market has won the favor of many users recognized.

1. The use of picosecond laser, ultra-short pulse processing without heat conduction; infrared picosecond glass cutting product features:

2. 0 perishable consumables, ultra-high stability;

3. The use of picosecond filament cutting process technology on the material "direct cut through";

4. Equipped with CCD visual positioning, offset correction compensation, "infinite correction";

5. PSO control-u level precision, path control real-time synchronization, to achieve "anisotropic cutting";

6. Cutting width can be customized.

In the future, Wuhan Sintec Optronics will also pay more attention to automation, precision cutting, new energy field of exploration and deep plowing, the whole series of Sintec Optronics family products are being updated and upgraded, with better quality and more professional service to the market. New laser infrared picosecond glass cutting technology as an innovative technology has been widely used in sapphire, optical glass, semiconductor packaging chips, silicon wafers, glass cover, 3C electronic glass cover and other transparent and brittle materials cutting and drilling process. Sintec Optronics has been focusing on laser industrial applications for many years, and is committed to providing professional laser industrial application solutions. Under the strategic planning of specialization, diversification and grouping, the product users have covered all the provinces in China and established business relationships with more than 160 countries and regions overseas, the localization of sales and service at home and abroad continues to upgrade, with professional quality and service in the laser industry market to establish a good brand image.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்