Laser Tube Cutting VS Conventional Tube Processing Similarities and Differences

Post epidemic era, with the trend of intelligent manufacturing, laser industry rapid development, laser technology and laser products are also becoming more mature. Laser processing subvert the traditional processing methods, help enterprises to transform and upgrade, intelligent manufacturing accelerate. Traditional tube processing methods have many steps, need to saw, milling, punching, drilling, etc., compared with the laser tube cutting, laser tube cutting only needs a piece of equipment and an operator, greatly improving efficiency, reducing costs, and forming competitive differentiation.

Light cut tube is widely used in various industries, continuous innovation and breakthroughs in tube splicing process, can realize riveting, round tube coherent line, square tube bending lap, bevel cutting lap and other processes.

1.Riveting

It can realize round tube and round tube riveting, square tube and square tube riveting, square tube and round tube riveting and so on.

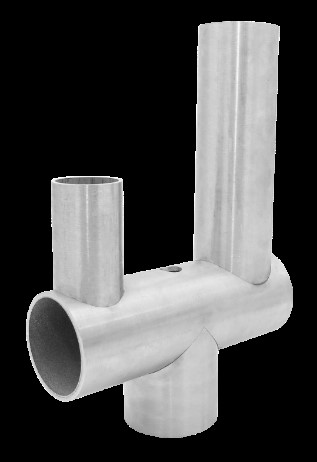

2 Round tube coherent line

Round tube coherent line cutting, mostly used in electric cars, bicycles and other industries for tube cutting.

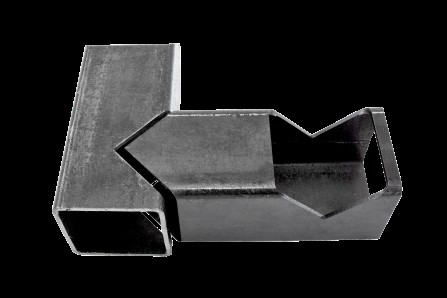

3 Square Tube Bending Lap

Square tube can be programmed to achieve V, R-port cutting, bending, can realize the seam is small, directly after the process of welding, mostly used in the furniture industry.

4 Bevel Cutting Lap

The bevel cutting head realizes ±45 degree swing cutting, and the splicing is tight and seamless to ensure the subsequent welding precision.

Laser Tube Cutting Machine - The Answer to Cost-Effective Needs

Efficient & Affordable: Explore an optimal solution in the trade-off of efficiency, reliability, and cost-effectiveness, so as to be both efficient and affordable; modular design, can be paired with different performance and price point of loading and unloading, to satisfy what you want.

Simple & Practical: A new generation of full-stroke pneumatic chucks and the seamless connection of rows of material loading and unloading to achieve accurate feeding, one-key clamping, automatic centering, simple and practical.

Saving & assured: equipped with a new generation of " intelligent brain " and the integration of Sintec Optronics exclusive " process formula ", so that the cutting process is more worry; a full range of software upgrade services and perfect after-sales service system allows you to use worry-free, buy assured.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்