What materials can be soldered by the syringe type laser solder paste soldering machine?

With the emergence of solder paste laser welding machine, it gives everyone another choice when buying a welding machine, but it also brings more problems. For laser welding machine, everyone may stay in the old welding process, so they always don't know how to choose between the old welding machine and the laser welding machine when choosing the welding machine. The reason why people are so hesitant is because they don't know enough about laser welding machines. Some people who use laser welding machines ask, ‘What is a laser welding machine? What industries can I use a laser welding machine for?

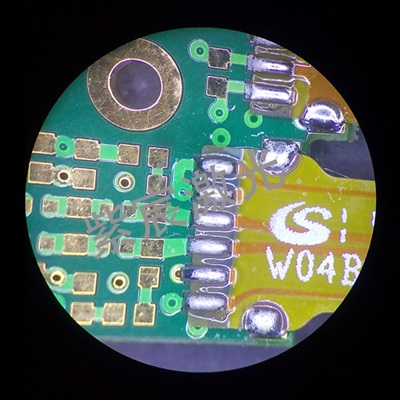

The basic principle of the Sintec Optronics syringe type solder paste welding machine is through the ‘wetting’, ‘diffusion’ and ‘metallurgy’ three processes are completed. Solder through the high-energy laser pulse in a small area of local heating and melting, wetting the solder joints and more solder inherent tension to the solder joints diffusion, and the solder joints of the metal layer contact to form an alloy layer, so that the two are firmly combined. It is a new type of welding, mainly used for welding thin-walled material precision parts, can achieve spot welding butt welding stacked seal welding, etc., weld width is small, small heat-affected zone of small deformation, welding speed, weld seam flat, welding quality, precision can be accurately controlled, high positioning accuracy, and it is very easy for customers to achieve automated production for customers to solve the cost of labour, production capacity, efficiency and management difficulties of the traditional old-fashioned The welding machine brings the trouble.

The welding process of laser soldering is divided into two steps: firstly, the laser solder paste is preheated, while the solder paste is preheated, the solder joints are also preheated, and then the high temperature melts the solder paste into a tin liquid, allowing the tin liquid to completely wet the pads, and ultimately forming a weld. The use of laser solder paste welding, with high energy density, high heat transfer efficiency, non-contact welding, solder can be solder paste or tin wire, especially suitable for welding in a narrow space or small solder joints precision welding. As well as for products with particularly high quality requirements, products that must be heated locally.

In response to the electronic market demand for automatic precision soldering, such as in the BGA outer lead bump, Flip chip chip on the bump, BGA bump rework, TAB device package lead connection, sensors, inductors, hard disk heads, camera modules, vcm voice coil motor, CCM, FPC, optical communication components, connectors, antennas, speakers, speakers, heat-sensitive components, photosensitive components and other products difficult to solder by traditional methods. components and other products that are difficult to solder in the traditional way, the application of laser soldering equipment is becoming more and more widespread.

Almost all of these industries use laser welding machines. The advantages of laser welding machines are energy concentration, non-pollution, small weld joints, wide range of weldable materials, high applicability, high efficiency and high welding speed. Also, the following requirements apply to laser welding.

1 Products that require a weld seam to be welded are welded with laser welding, not only is the weld small, but also does not need to be welded.

2 Products with a high degree of automation in which case the laser welding equipment can be programmed manually and the path is automatic.

3 Products to be welded at room temperature or under special conditions can be stopped at room temperature or under special conditions and the laser welding equipment is easy to install.

4 Some inaccessible parts require laser welding equipment It can weld inaccessible parts and achieve non-contact long distance welding with high sensitivity.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்